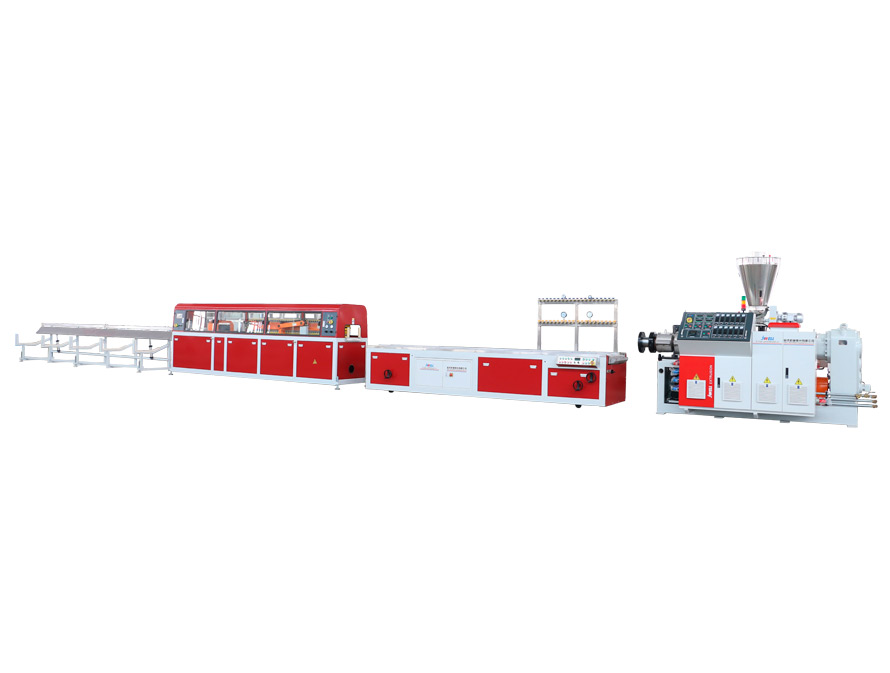

CPP, CPE Cast Film Extrusion Line

We are professional at manufacturing complete cast film extrusionline with over 25 years' rich experience, highly improving the production efficiency and extrusion technology. We also have exported many high-quality film production lines to different countries and provided reliable after-sales service including installation and operation on site or online. Our CPP, CPE cast film production line adopts good computer control system, special designed screw produced by our own company, high precision mold and professional pressure and temperature control system.

The cast film extrusion processis a plastic film production process, in which the raw materials are plasticized and melted by the extruder. The film is extruded through the T-shaped structure forming die and cast in sheet form onto the roll surface of the cooling roller that rotates smoothly. The film is cooled and cooled on the cooling roller to form a shape, and then the product is wound up after being pulled and trimmed.

Introduction of CPP cast film machine

We choose special T-Die for better extrusion efficiency and film quality, uniform flow mold channel with optimized design and simulation.

As one of cast film extrusion machine manufacturers, we have decades of rich experience in extrusion screw design based on our own screw manufacturing company founded in 1978, which means we're also professional at screw design and could provide reliable screw maintenance.

As one of extrusion machine manufacturers in china, we also have high-level CNC to ensure the precision processing of the core components.

We have a mature design and technical team to make the cast film linemore efficient and more stable for the long-term production.

Technical parameter of CPP Casting Film Extrusion Line

|

ModeI |

Width of die (mm) |

Products width (mm) |

Products thickness (mm) |

Max line speed (m/min) |

Max capacity (kg/h) |

|

JCF-3000PP |

3000 |

2700 |

250 |

800 |

|

|

JCF-3500PP |

3500 |

3200 |

250 |

1000 |

|

|

JCF-4500PP |

4500 |

4200 |

250 |

1400 |

|

|

JCF-5500PP |

5500 |

5200 |

250 |

1600 |

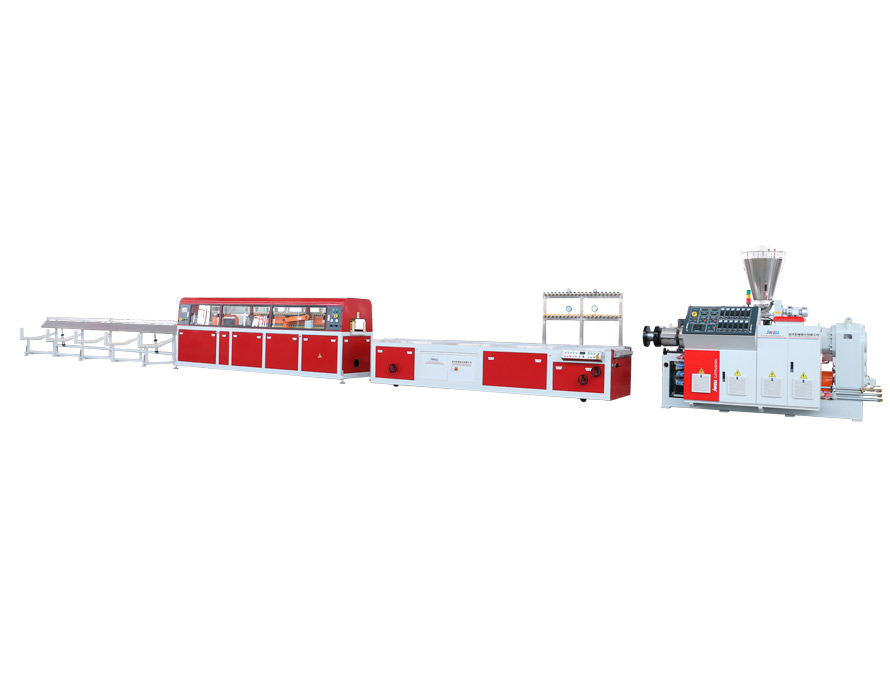

Introduction of CPE Casting Film Extrusion Line

Automatic and adjustable die head can realize on-line closed loop control, easy disassembly.

Thin wall and high efficient cooling roller, special spiral flow design, to ensure the high speed production film shaping effect.

Equipped with negative pressure double chamber vacuum box and static edge locking device to ensure the stability of film fusion.

High stability corona treatment device, low failure rate, according to the need to change direction, treatment of both sides of film.

Technical parameter of CPE Casting Film Extrusion Line

|

Model |

Width of die (mm) |

Products width (mm) |

Products thickness (mm) |

Max line speed (m/min) |

Max capacity (kg/h) |

|

JCF-2500PE |

2500 |

2200 |

250 |

600 |

|

|

JCF-3000PE |

3000 |

2700 |

200 |

750 |

|

|

JCF-3500PE |

3500 |

3200 |

200 |

900 |

The Application of CPP, CPE Cast Film Extrusion Line

CPP film after printing, bag making, can be used as clothing, knitwear, flower packaging bags, food packaging, candy packaging, and medicine packaging, etc.

CPE film laminated base material: It can be laminate with BOPA, BOPET, BOPP etc. heat sealing and bag making, used in food, clothing, and other fields;CPE single-layer printing film: Printing - heat sealing - bag making, used for roll paper bag, independent packaging for paper towels etc. CPE aluminum film: widely used in soft packaging, composite packaging, decoration, laser holographic anti-counterfeiting, laser embossing laser and so on.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Profile Extrusion Line | We have specialized in various plastic profile extruder machinefor over 25 years and accumulated rich experience of export and extrusion technology... | |

| PVC Ceiling Panel Extrusion Line | We've focused on providing good quality PVC ceiling panel extrusion linefor over 25 years since 1997, and have accumulated rich experience and matu... | |

| Corrugated Pipe Extrusion Line | Our company JWELL has accumulated extensive research and manufacture experience in various plastic pipe extrusion machines and relevant professiona... | |

| PLA Biodegradable Straw Extrusion Line | As a plastic extrusion line supplier, we have been focused on plastic pipe extrusion linetechnology since 1997, accumulating rich manufacture exper... | |

| PVC Wall Panel Extrusion Line | PVC Wall Panel Extrusion Line JWELL Machinery specializes in complete solutions for various PVC wall panel extrusion lines, from plant planing to ... |

Похожие товары

| High Vacuum Pump 2be 203 Series Water Ring Pump | Продавец: Greentech International (Zhangqiu) Co., Ltd | Application scope and characteristics: Greentech International (Zhangqiu) Co., Ltd is the profes... | |

| Advanced technology Electric regulating valve T967H-64 for thermal power plant | Продавец: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Advanced technology Electric regulating valve T967H-64 for thermal power plant The use of advanc... | |

| High Security Superheater outlet plug valve SD61H-P54.5150V for power plant | Продавец: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "High Security Superheater outlet plug valve SD61H-P54.5150V for power plant Deyang YOYIK is a st... | |

| "Low Failure Rate Bellows valves WJ10F-1.6 for power plant | Продавец: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Low Failure Rate Bellows valves WJ10F-1.6 for power plant Deyang Dongfang Yoyik is a trade produ... | |

| Customized Check valve H42H-16C for power station | Продавец: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Customized Check valve H42H-16C for power station Our company is equipped with high-precision cu... |