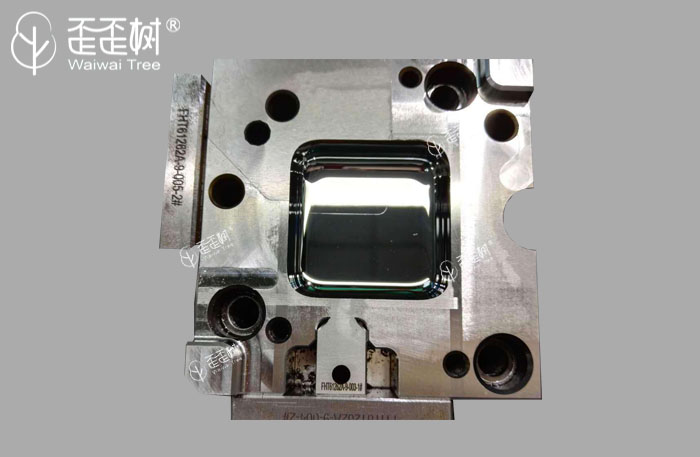

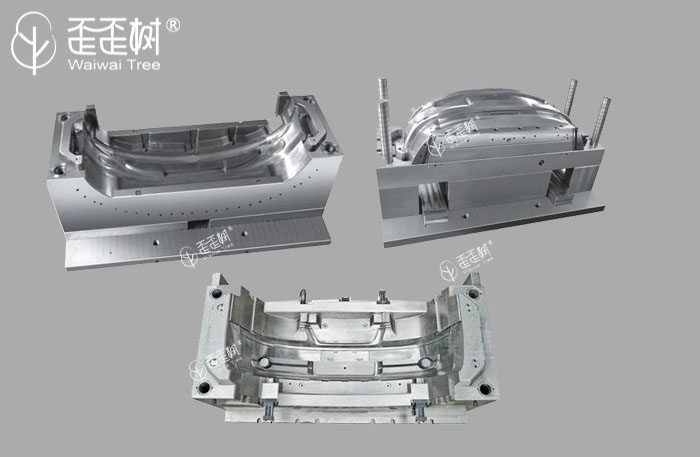

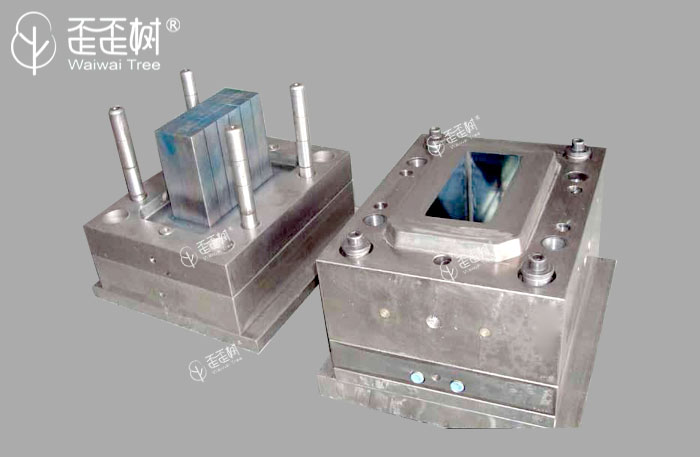

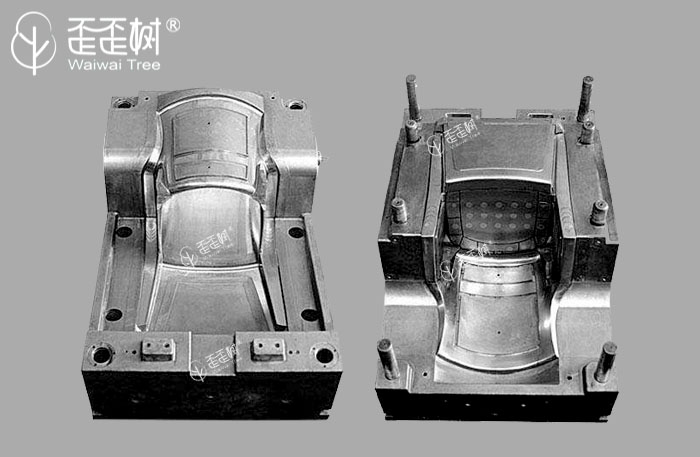

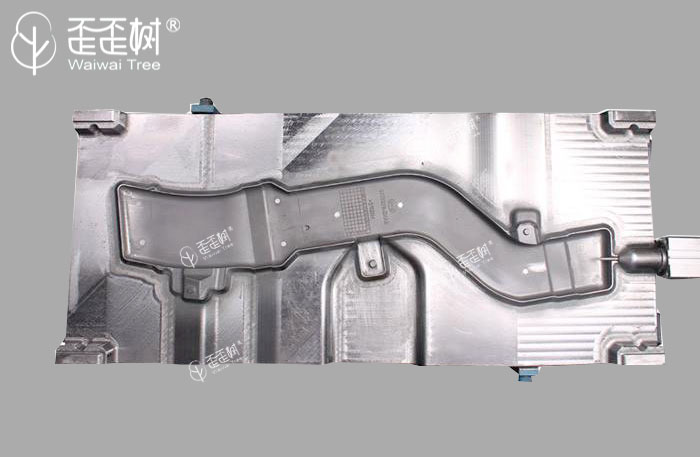

Auto Parts Mould

BMC Auto

Automobiles are different in size and shape. That means automobile suppliers always need flexible auto parts molds, once there occurs a new model of automobile. Over 90% of auto parts production depend on mold. BMC and SMC auto parts molds enable massive production and uniform specifications in production. Not only do the auto parts moulds successfully address the problems of light weight, electric leakage and automobile aging, but they also greatly reduce the costs and improve the quality of automobiles. BMC and SMC auto parts molds help lower the production cost and improve quality.

Auto Parts MouldManufacturer

A wide range of auto parts rely onauto part mould, from headlamp housings to under-the-hood electrical and heat-shielding components to exterior body parts and interior structural and cosmetic components. Our auto parts mould supply covers bumper molds, battery box molds, lamp molds, seat molds, engine intake pipe molds, electric control box molds and so on.

We have good knowledge and rich experience in SMC and BMC auto parts mould. For more information about car parts mould, please feel free to contact us by call or :

What BMC Auto Parts Mould Achieves

Long service life

Elegant appearance

Integral parts

No limits for shape and size

low weight

Easy assembly

Receptive to paint

Stable performance

High precision

Pressure Molding & Injection Molding for Auto Parts Mold

Pressure Molding for Auto Parts Mould

Make BMC auto partswith pressure molding starts with the fitting material into the mold. The raw material for the car parts mold will be heated with a hydraulic press until it has become more flexible and soft. This process is actually not easy in the way as it sounds. First, a carefully developed plan is required. The plan neeed to outline heat to be applied, the materials that are needed, the amount of force, and close monitoring to assure the final car parts mould can be produced with appropriate shape and dimension. The parts are ready for the finishing process as soon as the mold is opened. The finishing process of a qualified car parts mold includes painting, bonding, flashing, and installation of inserts for fasteners.

Injection Molding for Car Parts Mould

injection molding process is favored by the automotive industry due to its consistency and reliability. Automotive industry always involves mass production. Injection molding is an ideal for mass production requiring high quality. In addition, auto parts molds made in thermoset plastic materials are lighter and comparably durable to the metal BMC automobiles parts produced through the conventional means.

Aobang provide bmc composite, mbc automotiveparts, smc automobileparts, smc motor factorsand etc. Contact us to know bulk molding compound processor more.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

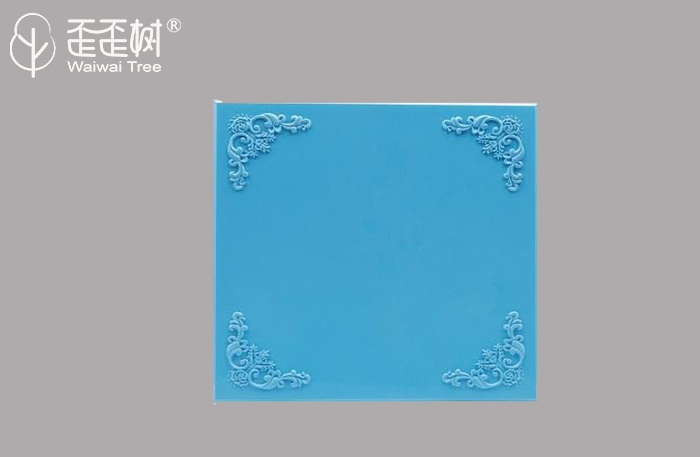

| BMC, SMC, GRP, GFK Wall Panel | Are you looking for smc composite? Aobang composite Wall Panel is divided into: BMC Wall Panel, SMC Wall Panel, GRP Wall Panel, GFK Wall Panel. Co... | |

| SMC/BMC Household Goods | SMC/BMC Household Goods Description Including: washbasin, laundry basin, trash can, platen, ceiling. SMC (sheet molding compound) materials are... | |

| SMC Auto Parts | SMC Auto Parts Description SMCauto partsmade from sheet molding compound (SMC) are typically 25-35% lighter than steel parts and aluminum produc... | |

| BMC, SMC, GRP, GFK Roof Tiles | What Is GFK Material BMC, SMC, GFK material, GRP roofing materialsare glassfiber reinforced plastic, also known as glassfiber roof, which are co... | |

| BMC, SMC, GRP, GFK Ceiling | Aobang composite ceiling is divided into: BMC ceiling, SMC ceiling, GRP ceiling, GFK Ceiling. The ceiling materials have been developed for more t... |

Похожие товары

| Motorcycle Body and Frame Plastic Mold | Продавец: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | Продавец: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | Продавец: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould | Продавец: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | Продавец: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |