PDC Cutters for Oil Drilling and Coal Mining

Description ofDiamond coated inserts PDC inserts

1.PDCcutters are sintered with selected diamond powder and tingsten carbide compact under high temperature and ultra high pressure.

2. The PDC cutters have high hardness, high abrasion resistance and high impact resistance.

3. PDC bttons bits can be widely used for oil and gas well drill bits, geological drill and mining drill bits. The PDC cutters can also be used as cutting tools with diamond for cutting, griding and polishing.

Application of PDC cutters:

PDC cutters are widely used for petroleum and oil field PDC bit, geological PDC exploration bits, gas exploration bits, PDC coal mining drill bits. PDC is mainly applicable for PDC drilling bit for drilling into soft and intermediate-hardness stratum.

Advantages of PDC cutters:

1.New cutting surfaces will appear during the course of abrasion, which keeps effective cutting rocks

2.high strength, high hardness and high wearing property of diamond layer as well as good self-sharpening

3.PDC drilling bit made of such PDC will break up rocks depending on shearing action when it works, which is more effective than crushing of rocks by roller cone bit or plowing and grinding of rocks by diamond impregnated bit

4.The serrate structure combination between polycrystalline diamond layer and hard alloy substrate allows more fixed combination between the two layers and more impact resistance of the whole PDC.

Sort by bit material

The mole PDC bit

The matrix diamond composite (PDC) bit is a cutting bit which is welded to the drill head via brazing.The matrix bit is sintered with tungsten-carbide powder, brazed on the tungsten carbide matrix with synthetic polycrystalline diamond composite sheet, and preserved with natural diamond.

Steel PDC bit

Steel PDC bit is machined with nickel, chromium and molybdenum alloys.After heat treatment, drill holes were drilled into the bit body, and the strong synthetic polycrystalline diamond composite was pressed into (tightly matched) the bit body.

According to applicable industry classification

The composite bit for geological exploration

The composite drill bit, mainly used in geological survey and exploration, is suitable for soft to medium hard rock layers. Now some manufacturers have developed a new composite sheet which can be applied to the rock layers with a tenth degree of hardness.

The utility model relates to a composite chip drill

It is mainly used for coal seam drilling and mining.Generally speaking, rock strata of coal field are relatively soft, and composite bit is widely used, such as anchor bit and three-wing bit.

Composite bit for petroleum exploration

Mainly used in oil and gas field drill bit.At present, the composite drill bit used in oil field is the cost and requirement of all composite drill bits.It's sort of the aristocracy of the composite drill bit.

The specifications of PDC cutter for oil drilling bits:

|

PDC Rock Cutter for Oil Well Drilling Bits |

|||

|

model |

product number |

size |

|

|

D(Mm) |

H(Mm) |

||

|

PDC-F |

F0505 |

5 |

5 |

|

F0804 |

8 |

4 |

|

|

F0808 |

8 |

8 |

|

|

F0810 |

8 |

10 |

|

|

F1008 |

10 |

8 |

|

|

PCD-C |

C1308 |

8 |

|

|

C1313 |

|||

|

C1613 |

16 |

||

|

C1908 |

8 |

||

|

C1913 |

|||

|

C1916 |

|||

|

C1919 |

19 |

||

|

PCD-S |

S1308 |

8 |

|

|

S1313 |

|||

|

S1613 |

16 |

||

|

S1913 |

|||

|

S1916 |

|||

|

S1919 |

19 |

||

|

PDC-G |

G1308 |

8 |

|

|

G1313 |

|||

|

G1613 |

16 |

||

|

G1913 |

|||

|

G1916 |

|||

|

CPD-(CSC)-R |

R1320 |

13 |

20 |

|

R1925 |

19 |

25 |

|

|

R1929 |

19 |

29 |

|

HowPDC cuttersaremade?

Cutters are made using a combination of high heat and high pressure. Man made diamonds can be grown in 5-10 minutes. Because of this diamond content, a fixed cutter bit may also be known as a diamond drill bit.

High heat plus pressure creates a PDC (polycrystalline diamond compact) cutter.Cutters are made from a carbide substrate and diamond grit. High heat of around 2800 degrees and high pressure of approximately 1,000,000 psi forms the compact. A cobalt alloy is also present and acts as a catalyst to the sintering process. The cobalt helps bond the carbide and diamond.

During the cooling process, the tungsten carbide shrinks at a rate of 2.5 times faster than the diamond. Controlling this stress, as with most aspects of drill bit design, is called Intellectual Property, and manufacturers rarely, if ever, share their secrets.

PDC Cutter for oil Industry

The diamond composite is composed of a layer of polycrystalline diamond and a hard alloy matrix.

Oil pdc cutter is will micro diamond powder and cemented carbide substrate and super high pressure high temperature (about 60000 atmospheres, 1400 - a - 1500 ℃) under the condition of sintering, made of.

Suitable for drilling in various layers of king kong composite chip bit (PDC bit).

The diamond grains in the polycrystalline diamond layer have complete d-d bond bonding, which makes the diamond layer have high strength, high hardness and high abrasion resistance, as well as good self-sharpening.

The rock is broken by shearing action, which is more effective than the crushing rock of the cone bit or the plough cutting and grinding rock of the diamond impregnated bit.

The combination of polycrystalline diamond layer and hard alloy matrix is in the form of tooth structure, which makes the bond between the two layers more solid and ensures the drill bit to be more resistant to impact.

Oil pdc cutter features

1. The leading position of pdc cutter quality stability is a prominent feature of HMR products, pdc cutter has been unanimously recognized by customers at home and abroad.

2. The advanced application for pdc cutter is ultra-high pressure and high temperature sintering technology ensures that the pdc cutter quality is in the leading level in China.

3. Through the study of different geological conditions and the application of advanced computer simulation technology, reasonable and effective tooth structure was designed, pdc cutter greatly optimized the product performance.

Can provide a variety of products for customers to choose, composite films can also be customized according to customer requirements.

4. Cooperate with customers to design and provide applicable PDCcutter solutions for customers according to their different needs, and improve together with customers.

Why choose our product

More SuperHard Products Co., Ltd is dedicated to finding solutions that help our clients in all markets succeed. More SuperHard has been manufacturing high-quality, competitively priced superabrasivediamond and cbn tools that are designed to perform in a wide range of industrial ,such as pcd tools grinding, natural diamond polishing, auto parts processing , thermal spray coated industry, optical glass, semicon and led industry, woodworking tool , cnc tool grinding and roll machining ,others ultral precision industry.

The company production and sales of products covered vitrified bond tools, resin bond tools, metal bond tools, electroplated diamond/cbn tools, vaccum brazed products, cvd diamond tools, polycrystalline diamond (pcd) tools, cubic boron nitride (cbn) tools.our objective is to meet all the customers’ needs and help every customer achieve maximum benefits. more brings in revenue for you, you win, we win!

More SuperHard supplies the wheels for several application mainly:

- Carbide round tools on cnc machines : flute grinding, gash grinding, end facing, clearance angle and cylindrical grinding .

- Insert grinding for machines such as: agathon, wendt, haas, waida and ewag.

- Woodworking saw blade and tools .

- Hss tools

- Cutting wheels

Products Range:

- 2. PCD milling tools, PCD turning tools, PCD drilling tools, PCD engraving tools, PCD/pcbn inserts, PCD/pcbn cutting tools, PCD/pcbn grooving tools, CBN inserts3. PCD/TSP diamond, CVD diamond tools, large size synthetic diamond, Natural diamond tools, diamond abrasive tools4. diamond grinding&cutting discs, diamond cutting blade, diamond cup wheel, diamond dressers5. Roller cutting tools, PDC cutters, PDC drill bits& PDC core bits6. PCD tool grinder & PCD grinding machine

|

If you have any questions, please contact us |

Whats App:

Tel:

URL:

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Flexible Diamond Belts Diamond sand belt for polishing and | Specification: The open dot pattern provides flexibility, aggressive cutting and reduced loading. The flexible backing also means they run great o... | |

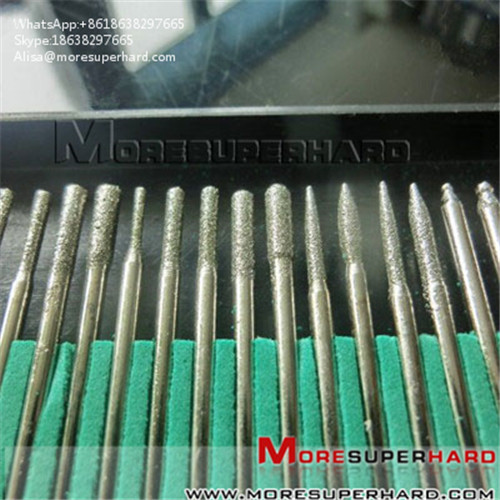

| Diamond Mounted Points & Diamond Burs | Applications of mounted points, diamond burs More Superhard diamond mounted points, diamond bur set are used for various applications, including c... | |

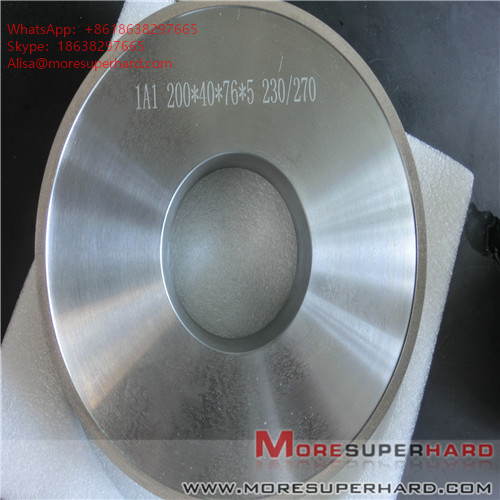

| 1A1Grinding wheels for magnetic materials | Description of metal bond diamond grinding wheel: Metal Bond Diamond Grinding Wheels are long grinding life, fast stock removal, excellent interru... | |

| electroplated diamond grinding head | Advantages of electroplaElectroplated diamond grinding head Electroplated diamond grinding head is a kind of grinding head grinding tool, which is... | |

| Surface coating hot spraying resin bond diamond grinding wheel | More SuperHard company provides a full range of thermal spray coating solution and service which includes OD grinding, inside grinding, cylindrical... |

Похожие товары

| hot-pressed diamond turbo cutting blade with protective teeth | Продавец: Corediam Tools Co.,Ltd | hot-pressed diamond turbo cutting blade with protective teeth The diameter of this segment blade... | |

| JXT Original Factory Precision Screwdriver Bit Set with6 Bits Magnetic Driver Kit Professional Repair Tool Kit | Продавец: 854584 | ||

| Titanium Alloy Mini Crowbar Multifunctional PortableEDC Tool with bottle opener flat head screwdriverkeychain ,Tritium slot | Продавец: 854584 | ||

| Multi Function Keychain Pry Tool EDC Key ChainCrowbar Titanium Pocket Tool Pry Bar With TimascusInserts | Продавец: 854584 | ||

| JXT Portable Titanium Professional Heavy DutyClimbing Carabiner Multi-Functional Tools Keychainwith Bottle Opener | Продавец: 854584 |