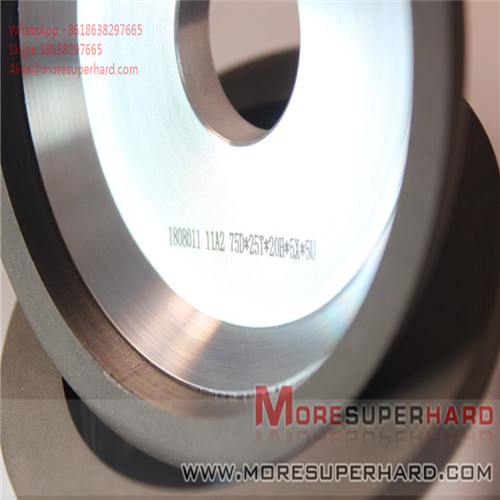

11A2 Diamond Grinding Wheel for Sharpening Drawing Dies and Tools Made of Hard Alloys

Introduction to resin diamond grinding wheel

The resin bond diamond wheels are mainly used for grinding tungsten carbide and non-metal materials. Various kinds of dimensions and shapes are available, such as flat shapes, cup shapes and dish shapes, etc.

Production of diamond grinding wheel with resin binder:

Resin as the bond material, metal powder, metal oxide, ordinary abrasive as filler mix to make the binding agent. The abrasive and binder are mixed into the molding material according to the requirements of concentration. The product is formed by hot pressing, curing and subsequent processing

Description:

brief description and superiorityResin Bond CBN Grinding Wheel1.High efficiency2.Little grinding heat3.Good sharpness4.Name brand product made in Chinadetailed descriptionResin Bond CBN Grinding Wheel

Application:

-11A2 Diamond grinding wheelsused for sharpening and finishing of front surface of reamer teeth,hobbing cutters,circular saws,drawing dies and tools made of hard alloys.

-Machining of glass,ceramics,quarts,semi-conductors, PCD & PCBN tools and other non-metallic materials.

*The abrasive layer of the diamond grinding wheel is made of synthetic diamond powder in resin or vitrified bonds.

Features of11A2 vitrified bond diamond grinding wheel:

Very Good Abrasion Resistance

Good Form-holding capability

Least Resistance to Damage

Chemical Stability

Controllable Stock Removal Rate and Surface Finish Characteristics

Heat Resistance

Well Performance

Specification of 11A2 diamond grinding wheel:

|

D(mm) |

T(mm) |

H(mm) |

X(mm) |

|

80 |

10-40 |

16, 20, 32, 40 Up on request |

Vitrified Bond wheel: 3,5,6,7,8,10 |

|

100 |

10-40 |

||

|

125 |

10-40 |

||

|

135 |

10-40 |

||

|

150 |

10-40 |

||

|

170 |

10-40 |

||

|

175 |

10-40 |

||

|

220 |

10-40 |

Resin diamond wheel products

1:resin cup diamond wheel

2:resin diamond polishing wheel

3: CNC resin diamond grinding wheel

4:resin diamond cutting wheel

5:resin diamond wheel for glass

6:resin centerless grinding wheel

Production process of Resin bond diamond grinding wheel

4: compression ring (let stand for a period of time to wait for molding)

5: back mould

6: the abrasive layer is air-dried

Cook for 10 hours at 7:670 degrees

8: cooling (prepare the matrix at the same time)

10: measure stationarity

Why choose our product

More SuperHard Products Co., Ltd is dedicated to finding solutions that help our clients in all markets succeed. More SuperHard has been manufacturing high-quality, competitively priced superabrasivediamond and cbn tools that are designed to perform in a wide range of industrial ,such as pcd tools grinding, natural diamond polishing, auto parts processing , thermal spray coated industry, optical glass, semicon and led industry, woodworking tool , cnc tool grinding and roll machining ,others ultral precision industry.

The company production and sales of products covered vitrified bond tools, resin bond tools, metal bond tools, electroplated diamond/cbn tools, vaccum brazed products, cvd diamond tools, polycrystalline diamond (pcd) tools, cubic boron nitride (cbn) tools.our objective is to meet all the customers’ needs and help every customer achieve maximum benefits. more brings in revenue for you, you win, we win!

More SuperHard supplies the wheels for several application mainly:

- Carbide round tools on cnc machines : flute grinding, gash grinding, end facing, clearance angle and cylindrical grinding .

- Insert grinding for machines such as: agathon, wendt, haas, waida and ewag.

- Woodworking saw blade and tools .

- Hss tools

- Cutting wheels

Products Range:

- 2. PCD milling tools, PCD turning tools, PCD drilling tools, PCD engraving tools, PCD/pcbn inserts, PCD/pcbn cutting tools, PCD/pcbn grooving tools, CBN inserts3. PCD/TSP diamond, CVD diamond tools, large size synthetic diamond, Natural diamond tools, diamond abrasive tools4. diamond grinding&cutting discs, diamond cutting blade, diamond cup wheel, diamond dressers5. Roller cutting tools, PDC cutters, PDC drill bits& PDC core bits6. PCD tool grinder & PCD grinding machine

If you have any questions, please contact us

Whats App:

Tel:

URL:

To meet your requirements in every way, we need the following information

----- Shape and Dimension of the wheels

----- Grit size (Mesh, refer to Table#1)

----- Concentration

----- Bond(Resinoid, Vitrified, Metallic, Electroplated)

----- Quantity

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| 14a1 resin CBN grinding wheel processed stainless steel plate | Introduction to resin diamond grinding wheel The resin bond diamond wheels are mainly used for grinding tungsten carbide and non-metal materials. ... | |

| Glass resin grinding wheel is used in straight edge machine and chamfering machine | Introduction to resin diamond grinding wheel The resin bond diamond wheels are mainly used for grinding tungsten carbide and non-metal materials. ... | |

| 164*6*105*3*3 metal bond diamond grinding wheels for stone/marble/granite grinding tools Manufacturer | Description of metal bond diamond grinding wheel: Metal Bond Diamond Grinding Wheels are long grinding life, fast stock removal, excellent interru... | |

| diamond and CBN honing stones are available for precisiom bore finishing | More Superhard product description: More Superhard Company specializes in the production of all kinds of high-end ceramic bonded and metal boned C... | |

| Metal Bond Diamond Grinding Wheel for Glass Machine | Brief introduction The superhard grinding wheel made by diamond or cubic boron nitride (CBN) is a metal sintering wheel with bronze and other meta... |

Похожие товары

| hot-pressed diamond turbo cutting blade with protective teeth | Продавец: Corediam Tools Co.,Ltd | hot-pressed diamond turbo cutting blade with protective teeth The diameter of this segment blade... | |

| JXT Original Factory Precision Screwdriver Bit Set with6 Bits Magnetic Driver Kit Professional Repair Tool Kit | Продавец: 854584 | ||

| Titanium Alloy Mini Crowbar Multifunctional PortableEDC Tool with bottle opener flat head screwdriverkeychain ,Tritium slot | Продавец: 854584 | ||

| Multi Function Keychain Pry Tool EDC Key ChainCrowbar Titanium Pocket Tool Pry Bar With TimascusInserts | Продавец: 854584 | ||

| JXT Portable Titanium Professional Heavy DutyClimbing Carabiner Multi-Functional Tools Keychainwith Bottle Opener | Продавец: 854584 |