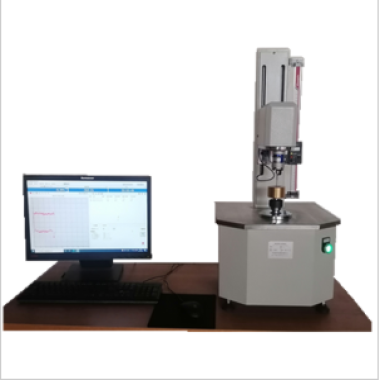

Dry Sand Rubber Wheel Wear Tester

The dry sand rubber wheel abrasion tester is mainly used to test the abrasion resistance of materials. Its working principle is to use a clockwise rotating rubber wheel to drive abrasive (such as quartz sand) to wear the sample, thereby evaluating the abrasion resistance of the material.

Application

Dry and wet sand abrasive wear testing machine is mainly used to evaluate the wear resistance of materials in dry and wet sand abrasive environment. By simulating the wear environment of dry sand or wet sand in actual working conditions, the testing machine can quantitatively test the wear resistance of different materials. This kind of equipment has a wide range of application value in material research and development, product quality control, industrial production and other fields.

Specifically, the main uses of dry and wet sand abrasive wear testing machines include:

Material research and development; In the development process of new materials, wear-resistant parts are an important performance index. Dry and wet abrasive wear testing machines can help developers quickly and accurately evaluate the wear resistance of new materials, thereby guiding the optimal design of materials.

Industrial production: In industrial production, many parts need to have good wear resistance to ensure product stability and service life. By using dry and wet sand abrasive wear testing machines to test parts, it can help enterprises screen out materials and processes with good wear resistance, thereby improving product quality.

Quality control: Dry and wet abrasive wear testing machines are also widely used in product quality control. Through the wear resistance test of the products produced, the unqualified products can be found and treated in time to ensure that the products flowing to the market have good resistance.

Standard

ASTM G65:Standard Test Method for Measuring Abrasion Using the Dry Sand/Rubber Wheel Apparatus

JBT_7705:Test Method for Abrasive Wear with Loose Abrasive Grains - Rubber Wheel Method

Dry and wet abrasive wear testing machines usually need to follow certain standards and specifications when testing. Here are some common applicable standards:

ASTM Standards: Standards developed by the American Society for Materials and Testing (ASTM) include content related to dry and wet abrasive wear testing. For example, the ASTM G65 standard may specify specific methods and requirements for abrasive wear tests of dry-sand rubber wheels; The ASTM G105 standard may specify specific requirements for abrasion test methods for wet sand rubber and rubber wheels. These standards specify parameters and requirements such as loading methods, abrasive types, test cycles, and data recording during the test process.

B Ash standard: China's machinery industry standard (B Ash) may also contain content related to dry and wet abrasive wear tests. For example, the JB/ 7705 standard specifies the rubber wheel method in the wear test method for loose abrasive particles, which can be used to evaluate the wear resistance of materials in dry sand environments. In addition, JB/T 9396 and other standards may specify the size of the sample, fixture design and other specific requirements.

When conducting dry and wet sand abrasive wear tests, it should be ensured that the selected standards are consistent with the test purposes and requirements, and the test methods and steps specified in the standards are strictly operated. At the same time, it is also necessary to pay attention to the calibration and maintenance of the testing machine to ensure the accuracy and reliability of the test results.

Feature

Its features include: Dry sand semi-free abrasive wear testing machine: such as the LGM-130 and MLG-130 models, conforming to ASTM G65 and JBT_7705-1995 standards, suitable for abrasion resistance testing of various metallic or non-metallic materials.

Wet sand semi-free abrasive wear testing machine: such as the LGM-225. conforming to ASTM G105 standard, suitable for wet sand abrasive wear testing.

Parameters

|

Model |

Q-27 |

|

Maximum load |

130 N |

|

rubber tire |

turn clockwise |

|

Rubber wheel speed |

200 + 10 rpm |

|

Rubber Wheel Diameter |

228.6 mm |

|

Rubber Wheel Hardness |

60 (Shore hardness) |

|

Size |

57*25.5 * 6mm |

|

Dimensions (L * W * H) |

710*740*1600 (mm) |

|

Weight |

420kg |

Accessoriess

Transmission system, sample fixture, fixture adjustment device, hardness measuring device, etc.

Test Procedures

Equipment Preparation: Ensure the testing machine is in good working order and inspect key components such as rubber wheels, abrasive jets, and clamps.

Sample Preparation: Prepare the specimens and perform necessary treatments according to the test requirements.

Test Procedure: Conduct wear tests, record wear data, and calculate the wear amount.

Result Calculation: Calculate the wear amount based on the test data and analyze the results.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Suitcases Vibration Impact Tester | This machine is used to test the shock resistance of various luggage handles, car stitches and overall structure. The method is to load the specifi... | |

| Bearing Friction Torque Measuring Instrument | Bearing friction torque is an important factor affecting bearing noise, vibration, and lifespan, and is a key indicator for measuring the dynamic p... | |

| Qinsun SUNTEST CPS+ | A practical desktop xenon lamp equipment with various accessories, customized to meet your SUNTEST needs. Here, you can see SunCool cooling devic... | |

| Fiber Composition Ratio Analyzer (for Fiber Blend Ratio Tester) | Product Introduction: It is used to measure the resistance value with a certain density under a certain geometry, and then converts it into the sp... | |

| Model Coin-cell Swelling System | The Model Coin-Cell Swelling System is designed for in-situ measurement of thickness and volume changes of coin-type lithium-ion cells during charg... |

Похожие товары

| Full-Body Garment Stress Tester,FZ/T 70015 | Продавец: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Продавец: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Продавец: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Продавец: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Продавец: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |