Plastic ball indentation hardness tester

The Plastic Ball Indentation Hardness Tester is a precision instrument designed to evaluate the mechanical and hydraulic performance of plastic drainage plates under specified pressures and water flow conditions. It measures seepage characteristics while applying lateral pressure and a defined hydraulic gradient, providing critical data for material selection, quality control, and design validation in civil engineering, construction, and drainage systems.

Application

(1) Testing the plane-direction seepage characteristics of plastic drainage plates under lateral pressure.

(2) Evaluating the hydraulic performance of drainage materials for civil engineering and construction applications.

(3) Quality control of plastic core plates used in drainage boards, geocomposites, and waterproofing systems.

(4) Research and development of new plastic drainage materials with improved mechanical and seepage performance.

(5) Assessing the effect of lateral pressure and hydraulic gradient on water flow through drainage materials.

(6) Calibration and verification of design parameters for drainage structures in tunnels, roads, and landscaping projects.

Standards

(1) JTG E50 T1143-2006 — Technical specification for drainage plate testing in highways.

(2) SL/T — Laboratory method for measuring water permeability of drainage materials.

(3) JT/T 521 Appendix A-2004 — Standard for plastic core plates in drainage applications.

(4) JTS-206-1 Appendix B B.3-2009 — Test method for plastic geocomposite materials.

(5) JTS/T 245-2023 — Hydraulic performance testing of drainage plates.

(6) ISO 12958 — Determination of water permeability of geosynthetics (comparable international standard).

Features

(1) High-precision customized pressure gauge with imported diffused silicon sensor and 16-bit A/D converter for accurate pressure measurement.

(2) Lithium sub-battery provides continuous operation for more than 1.5 years.

(3) One-click zero adjustment for convenient calibration in various environments.

(4) Supports six pressure units: kPa, MPa, Psi, mmHg, Bar, Kgf/cm².

(5) Open-type hatch door design for easy sample loading and unloading.

(6) Cast aluminum integrated molding ensures sealing of the pressure chamber.

(7) Specially designed sample holding device prevents deformation and ensures airtight and watertight conditions.

(8) Hydraulic gradient adjustable via water tower height.

(9) Optimized waterway pipeline design reduces head loss for more accurate measurement.

(10) Pneumatic control system to regulate compressed air inlet/outlet and lateral pressure.

(11) Customizable pressure chamber and seal plate to accommodate different sample sizes.

Technical Parameters

| Parameter | Specification |

|---|---|

| Test Chamber | Open-type structure |

| Effective Sample Length | 400 mm |

| Sample Width | 100 mm (customizable) |

| Side Pressure | 350 ± 20 kPa (gauge accuracy 0.4% FS) |

| Hydraulic Head Adjustment Range | 0–400 mm |

| Pressure Accuracy | ±0.4% |

| Host Dimensions | 715 × 300 × 260 mm (L×W×H) |

| Water Tower Dimensions | 440 × 440 × 860 mm (L×W×H) |

| Weight | 35 kg |

Accessories

(1) Sample holders and sealing plates (customizable)

(2) Water tower with adjustable head mechanism

(3) Pneumatic control unit for side pressure regulation

(4) Calibration kit for pressure gauge

(5) Connection hoses and fittings

Test Procedures

Install the plastic drainage plate sample in the test chamber and ensure it is securely clamped.

Adjust the water tower to set the desired hydraulic gradient (i = 0.5 or as required).

Activate the pneumatic control system to apply lateral pressure of 350 kPa.

Begin water flow through the sample and measure seepage over a specified period.

Record data for analysis, including water flow rate and any deformation.

Repeat the test for additional samples or varying hydraulic gradients as needed.

Maintenance Information

(1) Regularly clean the test chamber, water tower, and pipelines to prevent clogging.

(2) Inspect and calibrate the pressure gauge periodically for accurate measurement.

(3) Check pneumatic control valves and hoses for leaks.

(4) Store the instrument in a dry environment to prevent corrosion of the aluminum body.

(5) Replace the lithium sub-battery after 1.5 years or when low power is indicated.

(6) Ensure the hatch door and sealing components remain free of damage to maintain airtight and watertight integrity.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| UL94 Horizontal/ Vertical Flame Test Machine,IEC 60695,UL 94 Flammability Chamber | This machine is designed according to plastic Materials flammability test; It is used to test flammability, burning rate, flame spread, burning fla... | |

| Suture Needle Elasticity and Toughness Tester | The Elasticity and Toughness Tester for Suture Needles is a specialized device dedicated to detecting the physical properties of elasticity and tou... | |

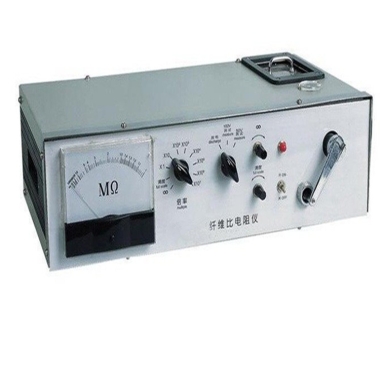

| Fiber Blend Ratio Tester | The Fiber Blend Ratio Tester is designed to measure the electrical resistance of a compacted fiber sample and convert it into the specific resistan... | |

| Flip Phone Durability Tester | The Flip Phone Durability Tester is a specialized testing machine designed to evaluate the fatigue life and mechanical reliability of clamshell and... | |

| Electric pencil hardness tester | The Electric Pencil Hardness Tester is designed to determine the surface hardness of coating layers applied to finished products by means of a stan... |

Похожие товары

| Full-Body Garment Stress Tester,FZ/T 70015 | Продавец: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Продавец: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Продавец: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Продавец: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Продавец: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |