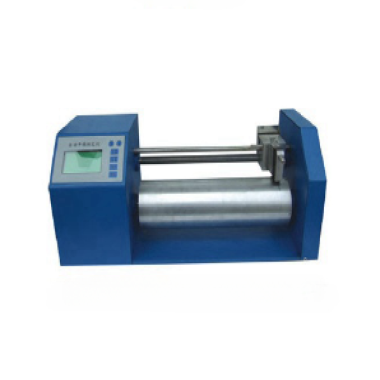

Initial Adhesion Tester

The initial - tack tester, also known as the initial - tack property tester or adhesive tape tackiness tester, is an instrument specifically used to measure the initial tackiness of materials.

Applications

The initial - tack tester is mainly used to test the initial tackiness of products such as adhesive tapes, medical patches, self - adhesive labels, and protective films. By simulating the actual use environment of adhesion, it tests the adhesive performance of these products when they are in brief contact with the adhesive surface under slight pressure. This device is widely used in multiple industries, including packaging, adhesives, printing, and pharmaceuticals, providing important data for product performance evaluation, quality control, and research and development. Specifically: - Packaging Industry: It is used to test the adhesive performance of adhesive tapes, carton - sealing adhesives, etc., ensuring the integrity of packaging during transportation. - Adhesive Industry: It is used for research and development and quality control. By testing the initial tackiness of different adhesives under various conditions, it provides data support for the development of new adhesives. - Printing Industry: It tests the tackiness of printing labels, such as trademarks and colored labels on self - adhesive labels, ensuring the reliability and durability of label products. - Pharmaceutical Industry: It tests the initial tackiness of adhesive materials in pharmaceutical packaging and medical plasters, ensuring the effectiveness of products and the medication experience of patients. In addition, the initial - tack tester can also be used to test the initial tackiness of office supplies such as sticky notes, and to evaluate the force required for the label to separate from the test substrate.

Standards

- GB 4852 Test Method for Initial Tackiness of Pressure - Sensitive Adhesive Tapes (Rolling Ball Method)

- JIS Z0237 (Japanese Industrial Standard) and other related standards

Features

1. Employs the inclined plane rolling ball method to test the instantaneous adhesion performance of the sample.

2. Test steel balls designed entirely according to standards ensure high accuracy of test data.

3. The test tilt angle can be freely adjusted according to user requirements.

Technical Parameters

| Technical Parameter | Specification |

|---|---|

| Testing Principle | Adopting the inclined-plane rolling-ball method: When slight pressure makes the steel ball briefly contact the adhesive surface of the test specimen, the adhesion between products (e.g., adhesive tapes, labels) and the steel ball is used to test the specimen’s initial tackiness. |

| Adjustable Inclination Angle | Freely adjustable within 0 - 60° according to user needs; adapts to testing requirements of different products. |

| Tabletop Width | Usually about 120mm; ensures sufficient space to place the test specimen. |

| Test Area Width | Generally about 80mm; provides a sufficient operational area for the test. |

| Standard Steel Balls | Size range: usually 1/32 inch to 1 inch; different-sized steel balls are used to test products with different adhesive forces. |

| External Dimensions | Varies by equipment/model: length 300 - 450mm, width 120 - 160mm, height 150 - 200mm. |

| Weight | Varies by model/brand; generally does not exceed 10kg, making it easy to move and place. |

Accessoriess

Main unit and a box of standard steel balls (sizes 1-32).

Test Procedures

1. Preparation

(1) Adjust the inclined plane ball rolling device to a horizontal position. Unless otherwise specified, adjust the inclination angle of the inclined plate to 30°.

(2) Use degreased gauze soaked in cleaning agent to wipe the glass surface and both sides of the polyester film, then wipe it clean with gauze.

(3) Soak the steel ball (after removing the rust-preventive oil) in a container of cleaning agent for several minutes. After removing it, repeatedly clean and wipe it with clean cleaning agent and gauze, then wipe it clean with clean gauze. After cleaning, use clean bamboo (wood, bone) tweezers or other tools to handle the steel ball.

(4) According to the standard, place the adhesive tape sample with the adhesive side facing up on the inclined plate. Cover the specified area with polyester film as the rolling aid section. The rolling aid section should be flat and free of defects such as bubbles and wrinkles. The 100mm range below the rolling aid section is the test section.

(5) Fix the two sides of the rolling aid section and the lower end of the sample to the inclined plate with adhesive. If necessary, adhesive tape can be used to fix the sample along both edges of the test section to ensure it adheres smoothly to the plate.

(6) Use tweezers to insert the steel ball into the ball release device. Adjust the front and back position of the ball release device so that the center of the steel ball is located on the initial rolling line. Before the formal test, a single sample can be tested multiple times, but the left and right positions of the ball release device should be adjusted so that the trajectory of the steel ball does not overlap each time. When the sample width is greater than 25 mm, the 25 mm wide area in the center of the sample is the effective test area.

2. Pre-selecting the largest steel ball

(1) Gently open the ball release device and observe whether the rolling steel ball is stuck in the test section (stop moving for more than 5 seconds). From largest to smallest, take steel balls of different sizes and perform appropriate tests until the largest steel ball that can be stuck in the test section is found.

(2) Take the largest steel ball and two balls of the same size that are connected to it, and perform one test on each on the same sample to confirm the largest steel ball.

3. Formal Testing

Take 3 samples and perform a rolling ball test on each sample using the largest ball size steel ball. If a sample cannot stick to the steel ball, replace it with a steel ball of a smaller size and perform the test again. If it still cannot stick, repeat the test as described in steps 1 to 3.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Safety Helmet High Temperature Pre-Treatment Chamber | The safety helmet high-temperature pre-treatment chamber is manufactured according to the GB/T2812-2019 standard for safety helmets and is primaril... | |

| Wrinkle Recovery Tester 丨Wrinkle Recovery Test mechine | Standards AATCC 128, ISO 9867, ENKA 3061 Applications AATCC Wrinkle Recovery Tester is used to determine a fabric's ability to recover after wri... | |

| Protective Clothing Resistance Test device | Related Standards GB/T 22042 - 2008 Clothing - Anti-static Performance - Test Method for Surface Resistivity GB/T 22043 - 2008 Clothing - Anti-st... | |

| Deval abrasion testing machine | The Deval Abrasion Testing Machine is designed to measure the wear resistance of stones and aggregates under dry or wet conditions. It provides rel... | |

| Ink drying apparatus | How it works: The working principle of the ink drying instrument is based on simulating the drying environment of the ink in the printing process,... |

Похожие товары

| Full-Body Garment Stress Tester,FZ/T 70015 | Продавец: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Продавец: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Продавец: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Продавец: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Продавец: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |