Box-Type UV Accelerated Aging Chamber

This test chamber simulates the hazards caused by sunlight exposure and rain. It utilizes fluorescent UV lamps to mimic sunlight and distilled water spray to replicate rainfall effects. Test materials are subjected to cyclic light exposure at controlled temperatures. The chamber can replicate months or years of outdoor hazards within days or weeks. Typical damages include: fading, discoloration, gloss loss, chalking, cracking, hazing, blistering, embrittlement, strength degradation, and oxidation.

Standards:

Standards Compliance:GB/T 14522-93(PRC National Standard:Accelerated Weathering Test Methods for Plastics, Coatings, and Rubber Materials in Mechanical Products)

Standard reference:ISO 4892. ASTM G151. G154. D4329. D4587. D4799. SAE J2020

Main parameters

UV Lamps: 8 units

Wavelength Range: UV-A (315~400nm)

Lamp Service Life: 1.500 hours

Temperature Range: RT+10℃~70℃

Temperature Resolution: 0.1℃

Temperature Uniformity: ±3℃

Temperature Control Mode: PID self-tuning control

Humidity Range: ≥75%RH

Distance Between Samples and Lamp Center: 25~45mm

Compliance Standards: GB/T 14522-93 (PRC National Standard:Accelerated Weathering Test Methods for Plastics, Coatings, and Rubber Materials in Mechanical Products)

Structure and Materials:

Working Chamber Dimensions: 660×1150×600mm (Depth×Width×Height)

Overall Dimensions: Approx. 780×1380×1780mm

Inner Chamber Material: SUS304 stainless steel plate

Exterior Material: SUS304 stainless steel plate

UV Lamps: UVA-340 fluorescent UV lamps (8 units, 40W each)

Water Supply & Consumption: 8 liters/day of purified or distilled water (user-provided)

Control System: 7-inch touch screen, PLC programmable controller

Test Equipment:

The chamber is constructed of corrosion-resistant metal materials, equipped with8 fluorescent UV lamps, sample racks, and temperature/time control systems with indicators.

Lamp Power: 40W per lamp.

Lamp Arrangement: Lamps are installed in a single row, with two groups of four lamps each controlled by separate switches.

Sample Installation: Test samples are fixed at a distance of 50mm from the nearest lamp surface.

Chamber Placement Requirements:

The chamber must be placed in a laboratory with an ambient temperature of 15~35℃, 300mm away from walls, and isolated from external heat sources.

Avoid strong airflow in the laboratory to prevent interference with light exposure and condensation conditions.

Test Conditions:

Sample Placement: Test samples are mounted on sample racks.

Test Temperature: Adjustable between RT+10~70℃ during light exposure, with a temperature tolerance of ±3℃.

Light/Condensation Cycles: Options include 4H light + 4H condensation, 8H light + 4H condensation, or other custom cycles.

Lamp Replacement: Replace 1-2 lamps after the first 400–450 hours of use. Subsequent replacements follow a rotational schedule to compensate for lamp aging, ensuring a service life of 1.600–2.000 hours per lamp.

Sample and Performance Evaluation:

Visual Assessment:

Primarily for coatings (gloss, color change, chalking, spotting, blistering, cracking, dimensional stability).

Plastics and rubbers may also be evaluated visually if required.

Quantitative measurements are recommended using instruments (e.g., gloss meter, colorimeter).

Mechanical and Other Properties:

Rubber: Tensile strength, elongation, hardness.

Plastics: Impact strength, elongation at break, tensile strength, flexural strength.

Additional tests may be specified as needed.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

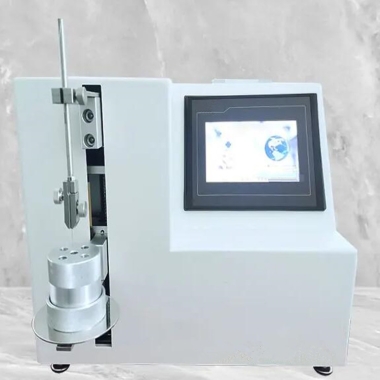

| Guide pin anchoring force tester | The Guide Pin Anchoring Force Tester is designed to evaluate the anchoring performance of mammary positioning wires and guide needles. It ensures t... | |

| Medical Face Mask Differential Pressure Tester | Medical face mask differential pressure tester also called mask breathility tester is to determine the breathability of medical face mask materials... | |

| FPC Flexibility Endurance Tester (for FPC Flex Durability Tester) | Standard ASTM F392 Product features 1. the stepper motor drive, high-precision positioning, low noise, can be used for a long time 2. program-c... | |

| Keyboard Key Life Testing Machine | The Keyboard Key Life Testing Machine is designed to evaluate the durability and lifespan of keys and buttons across electronic devices. It is suit... | |

| Solids Spontaneously Igniting Tester | Product Description Conforms to the UN Recommendations on the Transport of Dangerous Goods - Manual of Tests and Criteria 33.3.1.4 Test N.2: Test ... |

Похожие товары

| Full-Body Garment Stress Tester,FZ/T 70015 | Продавец: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Продавец: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Продавец: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Продавец: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Продавец: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |