Dry and Wet Retroreflectometer

The Dry and Wet Retroreflectometer, also known as the Dry and Wet Sand Abrasive Wear Testing Machine, is designed to evaluate the wear resistance of materials under simulated dry and wet sand abrasive environments. By replicating real working conditions, this equipment provides quantitative data on the durability and performance of various materials. It is widely applicable in material research and development, industrial production, and product quality control.

Application

This machine is suitable for a broad range of applications, including:

(1) Material Research and Development: Evaluate wear resistance of new materials, wear-resistant coatings, and industrial components to guide material design and optimization.

(2) Industrial Production: Test parts such as rubber components, protective coatings, and metal surfaces to ensure product durability and reliability.

(3) Quality Control: Assess the wear resistance of finished products, identify substandard items, and guarantee consistent product performance before market release.

(4) Extended Applications: Can be used for testing abrasion resistance of plastics, composite materials, polymer coatings, and safety textiles.

Specific products tested include: rubber wheels, industrial gears, protective helmets, reflective safety materials, plastic parts, and coated metals.

Standards

The machine complies with multiple international and national standards, including:

(1) EN ISO 20471:2013 – High-visibility clothing standards (reflective testing)

(2) ANSI/ISEA 107-2015 – American National Standard for High-Visibility Safety Apparel

(3) GB 20653-2006 – Chinese high-visibility safety clothing

(4) GB/T 18833 – Chinese abrasion-resistant material testing standard

(5) ASTM G65 – Standard test method for abrasive wear by dry sand/rubber wheel

(6) ASTM G105 – Standard test method for rubber wheel abrasion in wet sand conditions

(7) JB/T 7705 – China Machinery Industry Standard for loose abrasive particle wear testing

(8) JB/T 9396 – China Machinery Industry Standard for sample fixture design and test requirements

Features

(1) Simulates dry and wet abrasive environments for realistic wear testing.

(2) Adjustable optical detection system with precise angular settings.

(3) Standard light source (Light A, color temperature 2856K) with high-precision illuminometer (0.01 lux – 200 klux).

(4) Accurate sample positioning with adjustable spindle angles.

(5) Integrated water spray system with stable conical water column for wet abrasion tests.

(6) Time-controlled operation with high accuracy (0.01 min).

(7) Wide applicability across materials including metals, plastics, rubber, composites, and reflective textiles.

(8) Supports data consistency and reproducibility for R&D, QC, and production environments.

Parameters

| Parameter | Specification |

|---|---|

| Light source | Standard Light A, 2856K |

| Illuminometer | 0.01 lux – 200 klux |

| Optical detector angular aperture | ≤12′ |

| Observation angle (α) | 12′ – 2°, adjustable, accuracy 6′ |

| Angle of incidence (β) | 0° – 40°, adjustable, accuracy 1° |

| Sample holder | Accurate positioning between first spindle (β1) and second spindle (β2) |

| Distance from detector to sample | 15 m (requires darkroom), laser rangefinder configured |

| Nozzle diameter | 1.19 mm (conical and steady water column) |

| Nozzle distance to sample | 1000 mm |

| Sample size | 150 × 150 mm or 50 × 50 mm |

| Spray water speed | 284 mm/h |

| Timer | 0 – 99.99 min, accuracy 0.01 min |

Accessories

(1) Main testing unit – 1 set

(2) Sample holder spindles – 2 pcs

(3) Optical detector – 1 set

(4) Laser rangefinder – 1 set

(5) Water spray system – 1 set

(6) User manual in English – 1 set

(7) Certificate of Quality – 1 set

Test Procedures

(1) Mount the material sample securely in the sample holder.

(2) Adjust the optical detector, spindle angles, and distance settings according to the test requirements.

(3) For wet tests, ensure the water nozzle is properly aligned and the spray rate is set to 284 mm/h.

(4) Select the testing duration and start the cycle.

(5) Observe and record changes in reflectivity and wear, either manually or through integrated sensors.

(6) Analyze the results to determine compliance with the selected standard.

Maintenance Information

(1) Keep the optical system and illuminometer clean to maintain accuracy.

(2) Ensure the water spray nozzle and pipes are free of blockages.

(3) Regularly check spindle and fixture calibration.

(4) Maintain a controlled testing environment (darkroom for reflectivity tests).

(5) Perform routine checks on all electrical and mechanical components to ensure consistent

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Shoelace anti-siphon tester丨Shoelace anti-siphon test mechine | ||

| Photo fill light box | Standard CE & FCC Certified: Meets electromagnetic compatibility and safety standards for EU/US markets. RoHS Compliant: Lead-free constructi... | |

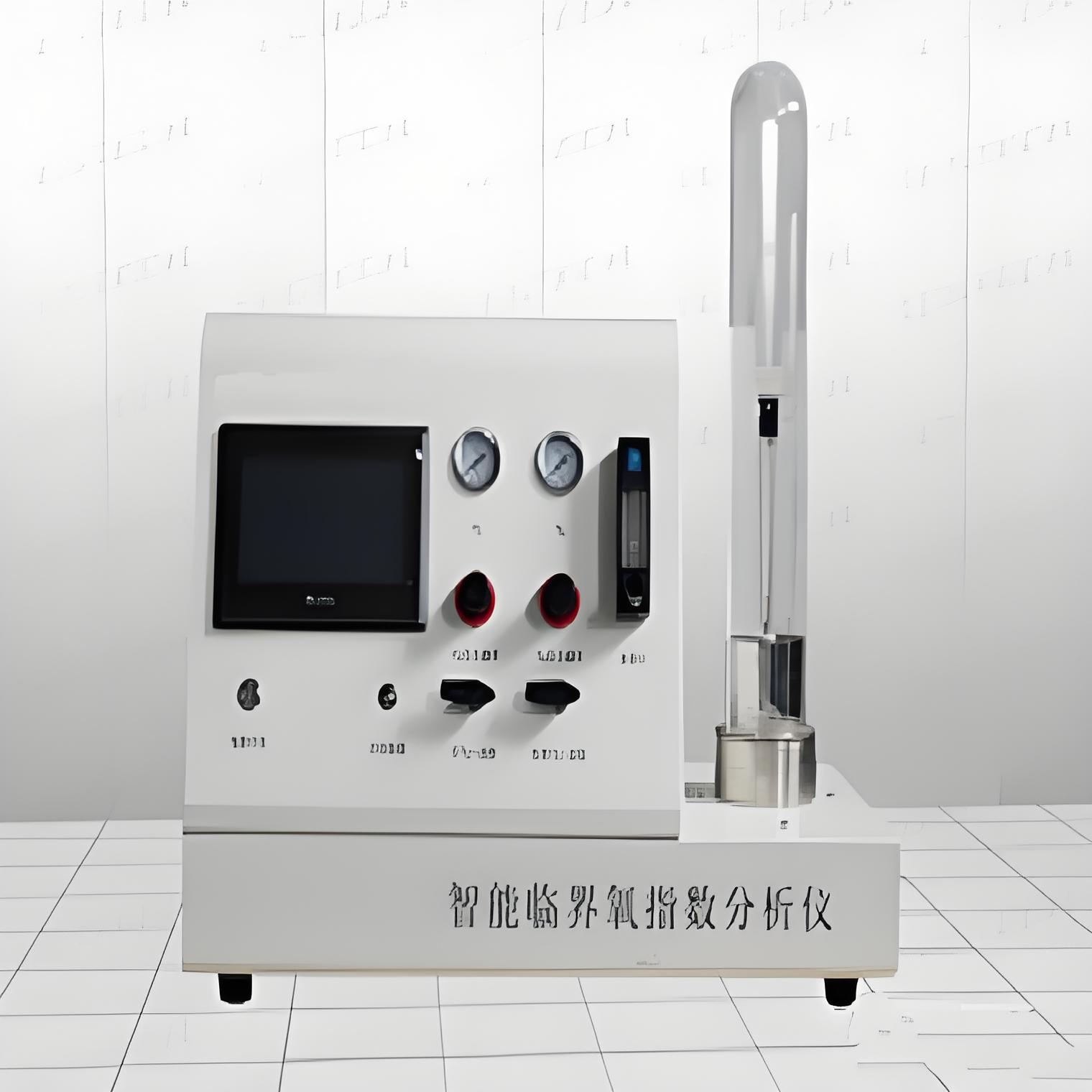

| Limited Oxyen Index Tester,Automatic oxygen index test machine | Introduction STD Limited Oxyen Index Tester for the determination under the test conditions specified in oxygen and nitrogen gas mixture just to m... | |

| Bone Plates Four-point Bending Fatigue Tester | Standard YY/T 1503-2016: Chinese standard specifying test methods for bending fatigue properties of metallic bone plates, requiring 1 million ... | |

| Battery combustion tester | The Battery Combustion Tester is designed for safety evaluation of lithium-ion batteries by simulating direct exposure to flame jet combustion unde... |

Похожие товары

| Full-Body Garment Stress Tester,FZ/T 70015 | Продавец: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Продавец: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Продавец: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Продавец: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Продавец: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |