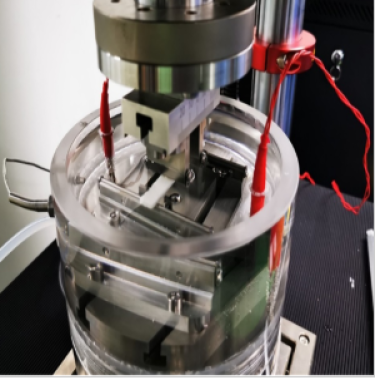

Helmets Vertical SpacingInfrared - positioning Tester

The helmet vertical spacing infrared positioning tester is a specialized instrument used to measure the vertical spacing and wearing height of safety helmets. It conforms to the GB/T 2812-2006 "Safety Helmet Test Methods" standard, and some models are compatible with the updated GB/T 2812-2024 standard.

Application

This measuring instrument is used to measure the vertical spacing and wearing height of safety helmets.

Standard

GB/T 2812-2006:Test method of safety helmet

GB 2811-2019:Head protection—Safety helmets

EN 397:Protective helmets for industry

Features:

Digital display: Uses a digital display scale for intuitive readings and to avoid human error.

Modular design: Supports the replacement of different head forms, adapting to various safety helmet sizes.

Efficient and convenient: Automated measurement process improves testing efficiency.

Compliant with standards: Strictly adheres to domestic and international safety helmet testing standards.

Parameters

| Technical Parameter | Description |

|---|---|

| Digital height gauge | Can display height in real - time, with a measuring range of 0 - 500mm |

| Positioning method | Adopts infrared positioning |

| Sample preparation for measurement | First, wear the test sample on the head mold specified by the standard according to standard requirements, and adjust it so that the heights on both sides of the hat hoop are consistent |

| Wearing height measurement | Measure the vertical distance from the lowest point of the bottom edge of the hat hoop on the side of the sample to the top of the head mold as the wearing height, record the measured value with an accuracy of 1mm |

| Measurement of X1 | Measure the vertical distance from the position of the point on the edge of the minor axis of the helmet shell relative to the head mold to the top of the helmet shell as X1 |

| Sample re - placement for X2 measurement | Remove the wearing system and cushioning liners, place the sample on the head mold again, and ensure that the posture of the helmet shell is the same as before removal |

| Measurement of X2 | Measure the vertical distance between the same points as X2 |

Accessoriess

Height gauge

Infrared positioning sensor

Head model (including two specifications, #1 and #2. corresponding to different wearing height requirements)

Digital display device (or touch screen control panel, used to display measurement data in real time)

Loading device (used to apply a load of 50N ± 1N to stabilize the sample during testing)

Test Procedures

Selecting the head form: Select the appropriate head form according to the standard. For example, use head form #1 when the wearing height is ≤85mm; use head form #2 when the wearing height is >85mm.

Installing the digital caliper: Fix the digital caliper to the selected head form using the given mounting holes.

Zeroing the caliper: Pull the digital caliper to the lowest position and press the zero button.

Adjusting the measuring feet: Measure the distance between the side headbands of the helmet and adjust the measuring feet to the appropriate length.

Wearing the helmet: Wear the helmet normally on the selected head form.

Measuring the data: Pull the digital caliper until the measuring feet touch the side headbands, read the value, and calculate the vertical distance and wearing height.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Reciprocating Friction and Wear Evaluation Apparatus | Applicable Standards ASTM Standards: Formulated by the American Society for Testing and Materials (ASTM), standards such as ASTM D6079 are used to... | |

| Micro-hole Detection Instrument | The pinhole tester for aluminum foil is a device specifically used to detect micro - pinholes in aluminum foil materials. The following is a detail... | |

| Absorbable Bone - connecting Plates Four - point Bending Tester | Standard ASTM F2119: Standard test method for constant load testing of bioabsorbable screws and washers, applicable to bending performance evalu... | |

| G631A electric shoe stripping testing machine | Product Introduction: Upper peeling strength tester is suitable for testing the peeling strength between the sole and the upper of the shoe, the p... | |

| Helmets Xenon Lamp Aging Tester | Standards ISO 4892-2: Plastics—Methods of exposure to laboratory light sources—Part 2: Xenon-arc lamps. ASTM G155: Standard practice ... |

Похожие товары

| Falling Sand Abrasion Test machine | Продавец: Standard International Group (HK) Limited | The sand abrasion tester is a specialized testing device used to evaluate the abrasion resistance... | |

| Conveyor Belt Drum Friction Testing Machine | Продавец: Standard International Group (HK) Limited | Main Purposes of Conveyor Belt Drum Friction Testing Machine The conveyor belt drum friction tes... | |

| Dry Sand Rubber Wheel Wear Tester | Продавец: Standard International Group (HK) Limited | The dry sand rubber wheel abrasion tester is mainly used to test the abrasion resistance of mater... | |

| Sliding Bearing Fatigue Testing Machine | Продавец: Standard International Group (HK) Limited | The sliding bearing fatigue testing machine is an important testing device, mainly used to evalua... | |

| High temperature vacum friction & wear tester | Продавец: Standard International Group (HK) Limited | The working principle of a high-temperature vacuum friction and wear testing machine is to simula... |