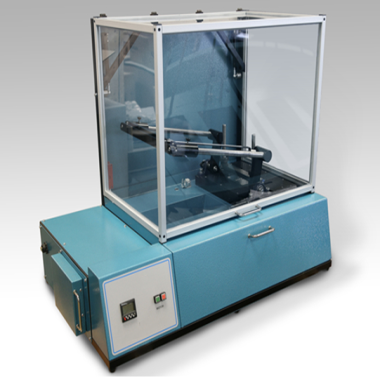

Micro Controll Constant-Speed Friction Plate Tester

A friction and wear testing machine is a device composed of a test force loading system, a friction force measuring system, an experimental clamping system, a temperature measuring system, a spindle system, a lubrication system, and an electrical control system.

Application

microcomputer control fixed-speed friction tester is mainly used to measure the friction coefficient and wear rate of automobile brake linings (brake pads), automobile clutch facings, oil drilling rig brake blocks and a variety of industrial machinery friction pads, motorcycle brake pads and other non-metallic friction materials.

Standards

GB/T5764-1998: brake linings for automobiles.

GB/T5764-1998: clutch facings for automobiles;

GB/T11834-2000: asbestos friction pads for industrial machinery;

SY/T5023-1994: brake blocks for oil drilling rigs.

Feature

Strictly in accordance with the provisions of the GB5763-98 standard, in keeping with the basic principles and structure of Japan's HP-S-type prototype machine based on the combination of modern technology to improve the design and become.

1 electromechanical integration of the whole structure, the user wiring available.

2 force measuring organization force flow in the same plane, completely solve the mechanical vibration problem.

3 gravity code calibration device, so that the measurement is more accurate.

4 stainless steel heating and cooling cover, wet parts of all nickel-plated rust-proof treatment, stainless steel nickel wire heater;

5 pre-furnace assay electric furnace precision casting friction disk.

9 increased cooling fan to prevent water vapor sprayed onto the surface of the friction disk and affect the measurement data.

10 adopted a new way of measuring force, canceled the vibration damping device, improve the measurement accuracy.

11 host and console compact structure, beautiful appearance, can realize the automatic circulation of cold water and drainage.

Parameters

| Items | Details |

|---|---|

| Control System | Independently researched and developed by Jinan. Utilizes a laptop plus lower computer control software for closed-loop control experiments, enabling real-time control of the test process, collection and analysis of test data, automatic processing of test results, and drawing of curve analysis reports. |

| Temperature | Measurement and control range: 0 ~ 260 ℃ (up to 350 ℃); Measurement accuracy: 1 ℃; Measurement error: 5 ℃ |

| Friction | Measurement range: 0 ~ 2000N; Measurement accuracy: 0.2N; Measurement error: 10.0N |

| Mo Disc Rotation | 480 ~ 500r/min; Measurement accuracy: 1 turn; Measurement error: 1 turn |

| Power | Main unit: 7.5kw; Heating pipe: 4.5kw; Fan: 120w (two fans, total 240w considered in total power calculation); Total power: 12.12kw |

| Friction Disk | Material: Gray cast iron HT-250; Brinell hardness: 180~220HB; Pearlite structure |

| Specimen | Not specified |

| Friction Radius | R = 150mm |

| Positive Pressure | 0.49Mpa - 0.98Mpa |

| Loading Weights | 1.25kg - 1 piece; 2.5kg - 3 pieces |

| External Shape Dimensions | Not specified |

| Control Cabinet | 800×600×1000 |

| Weight | About 1000kg |

Accessoriess

The main components of a sliding bearing PV friction testing machine include the headstock, tailstock, tool holder, torque sensor, force sensor, spindle assembly, loading system, linear guide rails, air bellows, and motor.

Test Procedures

Sample Preparation: Load the sliding bearing sample to be tested onto the test rig, ensuring its surface is clean and smooth.

Load Application: Apply a specific force or pressure to the sample surface using the loading system, simulating the load conditions under real working conditions.

Start of Test: Start the test machine control system, controlling the movement speed and load changes of the test rig according to preset conditions, and begin simulating the friction and wear process.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Pipe coating scratch tester | The Pipe Coating Scratch Tester, also known as a paint and varnish scratch resistance tester or balanced scratch rod adhesion tester, is a precisio... | |

| Shoe Shank Stiffness Tester | This machine evaluates the thermal insulation and moisture permeability performance of the entire shoe by measuring its heat retention, moisture ab... | |

| Bending Tester STD- FB2 - S | Compliance Standards ASTM D790 (Plastics Flexural Properties) ISO 178 (Flexural Strength of Rigid Plastics) SAE J2748 (Automotive Composite Flex... | |

| Carbon Black Content Tester | A Carbon Black Content Tester is an instrument used to measure the carbon black content in materials. Applications The Carbon Black Content Teste... | |

| Falling Sand Abrasion Tester | The falling sand abrasion tester is used to test the abrasion resistance of coatings under standard conditions. This method tests the abrasion resi... |

Похожие товары

| Thrust Bearing Rolling Friction and Wear Testing Machine | Продавец: Standard International Group (HK) Limited | Applicable Standards: ASTM D3702 ASTM G99 ASTM G77 ISO 18535 Product Advantages: Simulates ... | |

| Falling Sand Abrasion Test machine | Продавец: Standard International Group (HK) Limited | The sand abrasion tester is a specialized testing device used to evaluate the abrasion resistance... | |

| Conveyor Belt Drum Friction Testing Machine | Продавец: Standard International Group (HK) Limited | Main Purposes of Conveyor Belt Drum Friction Testing Machine The conveyor belt drum friction tes... | |

| Dry Sand Rubber Wheel Wear Tester | Продавец: Standard International Group (HK) Limited | The dry sand rubber wheel abrasion tester is mainly used to test the abrasion resistance of mater... | |

| Sliding Bearing Fatigue Testing Machine | Продавец: Standard International Group (HK) Limited | The sliding bearing fatigue testing machine is an important testing device, mainly used to evalua... |