Automatically Interchangeable Steel Forming Machine

Все товары поставщика

We also can design the as per your required profile drawing

SURFACE TREATMENT

- Main Features

Quick size change

CZ 75-300 quick , it adopted semi-automatical size adjusting system, operator push buttons, the size adjusting system adjust different desired sizes automatically. Size changeable by 1mm, (such as 75, 76, 77, …80…100, 101, 102, 105,...280, 300) .

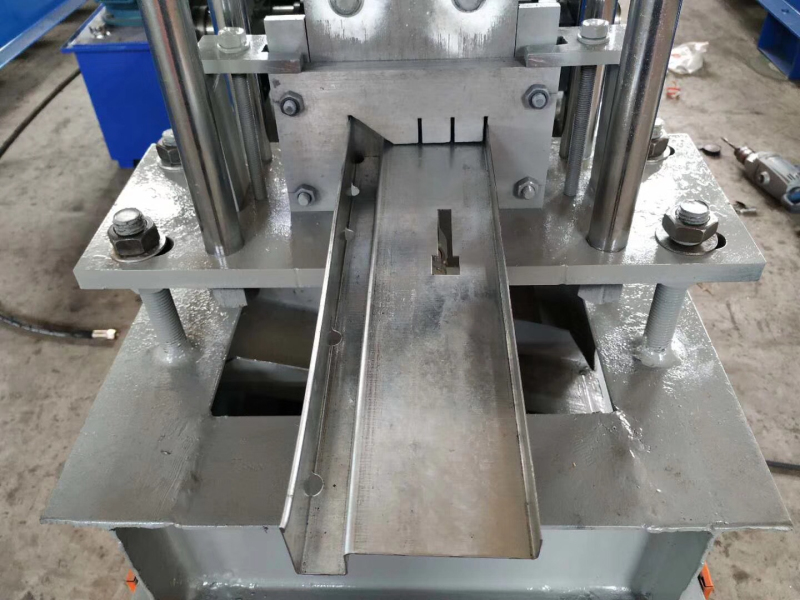

Quick C-Z change

CZ interchange through 180 degree rotate, re-tighten the screws. Nothing need to be removed or changed. It is simple and quick.

The whole line adopted automatic controlling system which controls cutting equipment and roll forming processing according to operator's order on the PLC, such as length, quantity etc.

This line roll forming speed can reach 8-15m/min.

The roll forming machine composed by drive motor, main frame, roll forming rollers and size adjusting device.

Forming roller drive motor: 15KW, hard gear faced speed reducer and variable speed adjusting, encoder control brake.

Main frame adopts channel steel to construct the girder, and welding a steel plate to strengthen the structure.

Two side separated forming rollers line for roll forming, 11 groups back rollers of one side were fixed on the machine base, then the fixed part of rollers set a baseline for other three side roller groups. The roller groups adjusted by hand slide leading screws according to different sizes of manufacturing sheet, and it adopted a bevel gear drive between two slide leading screw to synchronize the two side, it has self-lock function as well.

By adjusting eccentricity of the driven rollers can adjust the forming thickness. Thickness variation not required to be adjusted except for big difference.

C&Z interchanging adjustment through 180 degree rotate by hand.

Change two edging rollers to produce 90 degree lip Z purlin.

TECHNOLOGY

CZ 75-300 quick is comprised of 3T manual decoiler, in-feed guiding device, 7 rollers leveling device, CZ quick interchangeable roll forming machine, punching device, cutting device, auto controlling system, hydraulic system.

SALES TERMS

1). Machine Price: Please contact us, we will try to give you good discount for starting our cooperation

2). Payment term: 30%TT should be paid as advance deposit, 70%TT before shipment

Or 100% LC at sight

3). Package: naked with simple plastic film and loaded in one 20-feet container

4). Delivery time: 50 working days after receipt of the deposit

5). Guarantee: 12 months. If any part of machine breaks, we will supply it for free.

6). After sales service

This producing line is maintained free of charge for 12 months. When the machine is used in China, we will install and debug the machine for free; if it is used at abroad, we will send the professional technician to debug. Buyers should take all the fees for technicians traveling abroad, and pay 100USDdayperson.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

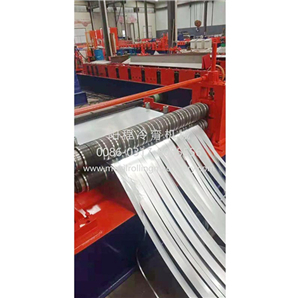

| YC Automatic 1.25M-1.5MM Steel Coil Slitting Line | Автоматическая линия продольной резки ТЕХНИЧЕСКИЕ ХАРАКТЕРИСТИКИ Гидравлический разматыватель с тележкой для рулонов → платформа подачи →... | |

| Door Frame Roll Forming Machine | we also would like to design the as per your required profile drawing SURFACE TREATMENT Special designed steel door frame cold roll forming equ... | |

| 65-Ton Clamp Punching Machine with Auto Feeding Device | 65-Ton Punching Machine We can also design the according to your required profile. SURFACE TREATMENT (1) Processing material: steel trip (2) Mater... | |

| Roller Shutter Roll Forming Machine | 1. Профилегибочная машина для производства стальных роллетных дверей YC 122-16 Профилегибочная машина для производства роллет ОБРАБОТКА ПОВЕРХНОСТИ... | |

| EPS&Rock Wool Insulated Sandwich Panel Production Line | We also can design the as per your required profile drawing SPECIFICATIONS Composite De-coiler(4 sets)—Roll Forming Machine --laminating sy... |