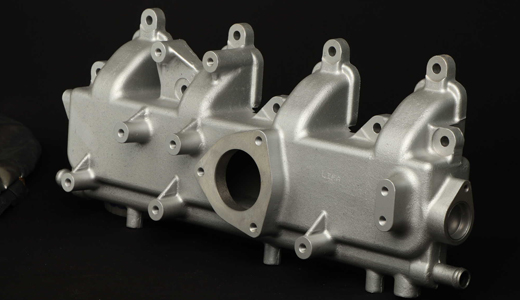

Sodium Silicate Sand Casting

Sodium silicate is a generic name for chemical compounds with the formula Na2SiO3. This material is generally colorless transparent solids, or in white powder, non toxic and non-inflammable. It is suluble in water in various amount. A more common name for sodium silicate is water glass, which is used in the iron or steel sand casting. The water glass works as a binder of the sand. It allows the rapid production a strong sodium silicate sand casting mold, by CO2 through the mixture of sand and sodium silicate in the mold, which hardens it almost instantly. Basic Property of Sodium Silicate Casting Product dimension tolerance ±0.5mm, CT7~8. surface finish Ra3.2. wall thickness up to 7mm. unit weight extent 1~20000kg. unit size limitation 0.03~3.5 meter. degree of complexity- complex. machining required- normal production lead time- short. production cost- low. Notice of Sodium Silicate Sand Casting Though in most conditions, sodium silicate sand casting is considered to be investment casting, but actually it also could be applied in the sand casting. Besides, sodium silicate sand casting is more suitable to make the large and complex structures and with even better surface finish and less defects. Principle of Sodium Silicate Casting The principle of sodium silicate casting industry and the detailed steps: melt the glass and mold it through the mold. Generally realize that after the mold is made, the glass melt is injected into the mold or realize that the pre-made mold is stacked with glass scrap in the mold, and put into the furnace together with the mold for melting, and anneal the mold with the glass domain anastomosis after molding. Rayforce Manufacture is a private foundry supplier, we provide metal casting china, silica sand casting and etc. Want to know more? Please contact us.

Другие товары поставщика

|

|

Sand Casting |

Sand casting chinais the most commonly applied method for casting the metal part. It suits most of the raw materials, ferroalloy, and non-ferroallo... |

|

|

Silica Sol Investment Casting |

The silica sol also shares the name of water glass in general. It is used in the metal casting process as mold adhesive which is mixed with sand an... |

|

|

Investment Casting |

Investment casting, also called the lost-wax casting process, is actually an ancient metal casting technology with a history of over 6,000 years. I... |

|

|

Vacuum Investment Casting |

Vacuum investment casting is one of the precision investment casting methods. This special technic is mainly applying to producing the small but hi... |

|

|

Resin Sand Casting |

Resin sand castingis a kind of floor molding process, by mixing the resin with quartz sand and solidification agent, to create the very hard and so... |

Все товары поставщика

Похожие товары