contiunous galvanized line equipment with Primetals technology supplier,process-optimized hot-dip galvanizing lines supplier

contiunous galvanized line equipment with Primetals technology supplier,process-optimized hot-dip galvanizing lines supplier

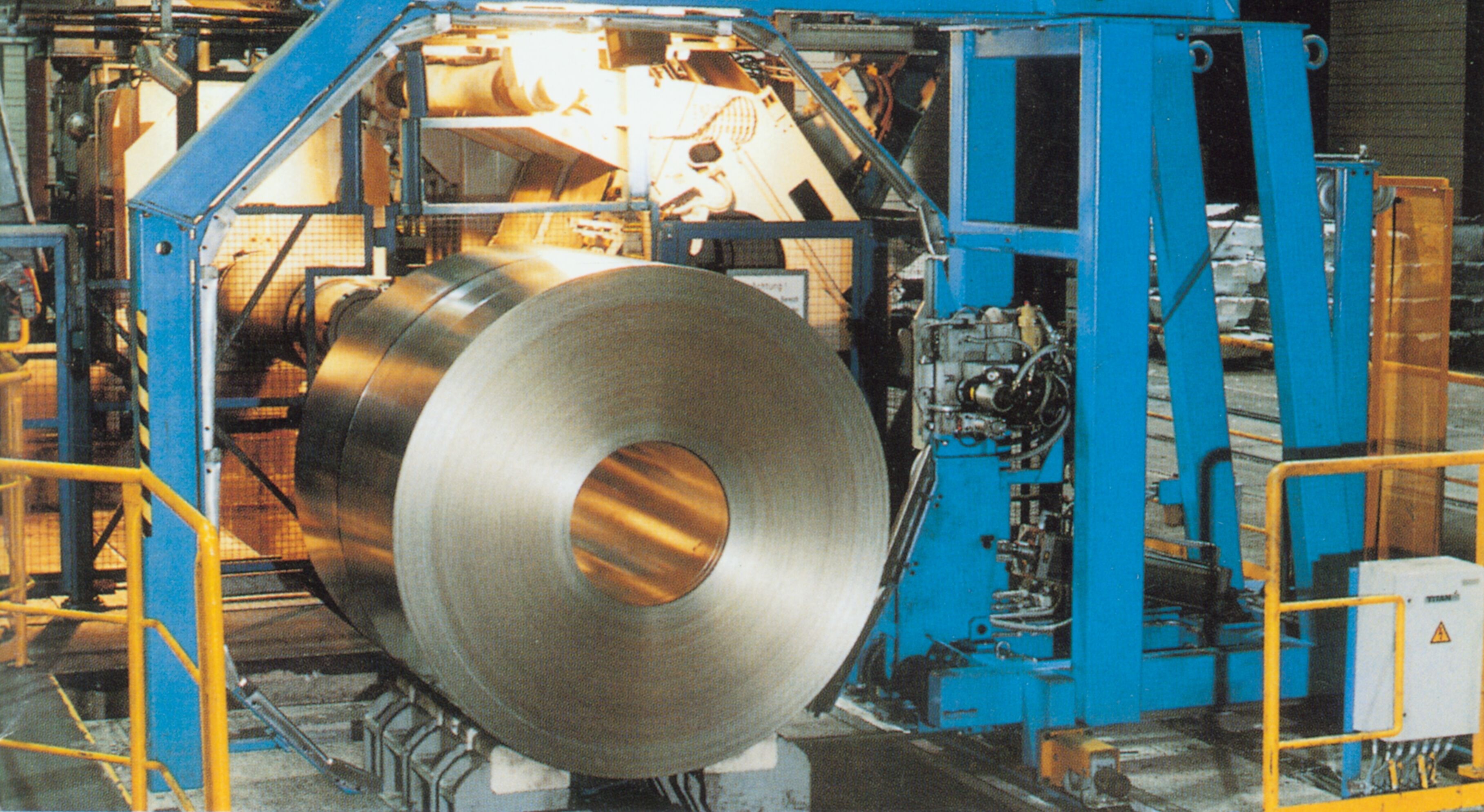

we supply process-optimized hot-dip galvanizing lines that make the grade with high speeds and zinc coatings to ultra-close thickness tolerances. Included here are air knives that automatically control and set the desired thickness of the zinc coating. Depending on the surface quality, air or nitrogen is used to remove the liquid zinc. It's essential for the high precision of this process that the strip runs smoothly in the area of the air knives. Next in line is an exactly defined cooling process in the downstream air and water cooling section. At the end of the process, galvanized sheet strip that meets the high quality demands of international markets leaves the production line.

Main features of the hot dip galvanizing line:

adopt the advanced American-Steel-Union process technology

adopt electrolytic degreasing process, which clean the strip surface with high degree, to guarantee high surface quality of the strip and good adhesiveness of the coating layer.

annealing furnace adopts all gas radiant tube heating method, so that it has high efficiency and high product quality.

exhaust gas of the annealing furnace adopts three times heat recovery technology, which could greatly save energy consumption.

annealing furnace adopt light fiber as lining, which has quick furnace building and small thermal inertia

zinc pot adopts ceramic induction pot of jet flow type

adopt mature air knife equipment, which can control the zinc coating weight very well

fast cooling after galvanizing sufficiently consider the galvalume product cooling speed requirement

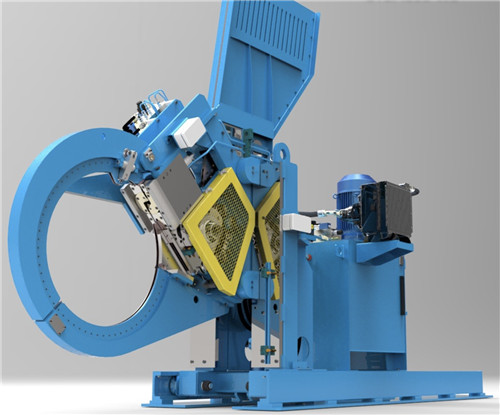

equipped with skin pass mill, which can improve the surface quality effectively, eliminate the yield point elongation and improve process ability.

adopt two-bending and one-stretching leveler, which can improve the strip shape quality

adopt Siemens ACVF speed regulation drive control system, which has high degree of automation.

For more detailed information, please feel free to contact us. Sinom at sinomgroup dot com

Contact informaiton:

Tel:

Mobile:

Web:

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| China largest airport conveyor system equipment supplier | China largest airport conveyor system equipment supplier SINOM supply the airport baggage conveyor system to airports worldwide. The airport belt c... | |

| Tundish preheating & drying station/Tundish preheaer is for tundish temperature rising | Tundish preheating & drying station/Tundish preheaeris for tundish temperature rising Tundish preheating & drying stationis special equipme... | |

| Rebar and H Beam Bundling/Tying Machine supplier | Rebar and H Beam Bundling/Tying Machine supplier Rebar and H Beam Bundling/Tying Machine Main Features of SINOM rebar Bundling Machine/ tying mach... | |

| coil strapping machine for coil rolling mill | Strapping machine to strap coils on circumference way with perpendicular axis to coil travel. The machine can be equipped with side compression dev... | |

| oilless bearing/ sliding bearings/self-lubricating bearings/copper bushes/oil-less copper brushes supplier/manufacturer | oilless bearing/ sliding bearings/self-lubricating bearings/copper bushes/oil-less copper brushes supplier/manufacturer We are specializing in prod... |

Похожие товары

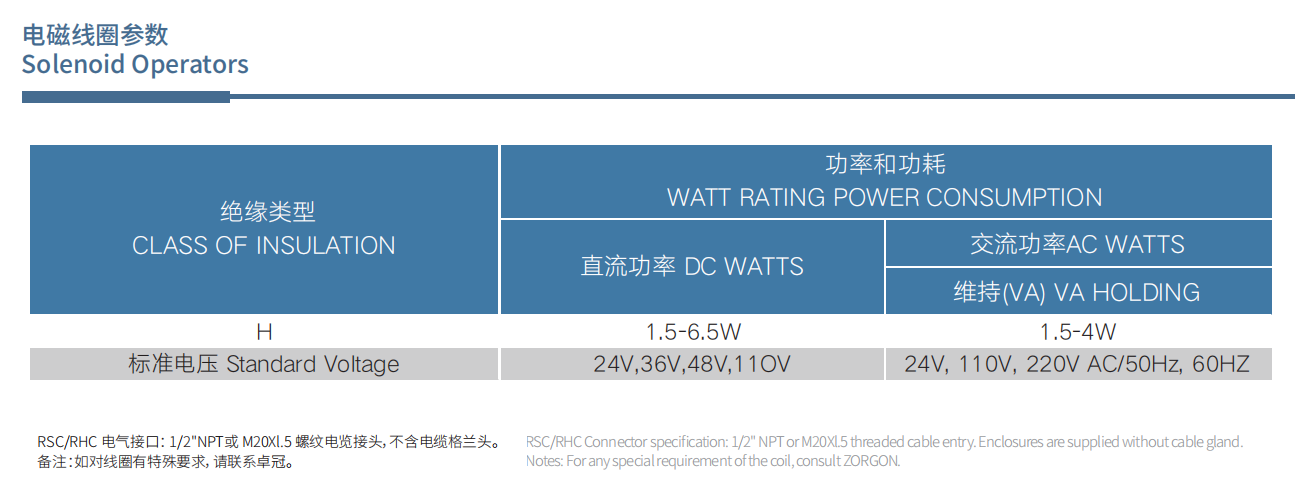

| Электромагнитный клапан серии 151 | Продавец: ZORGON | Электромагнитный клапан серии 151. В технологическом производстве электромагнитные клапаны часто ... | |

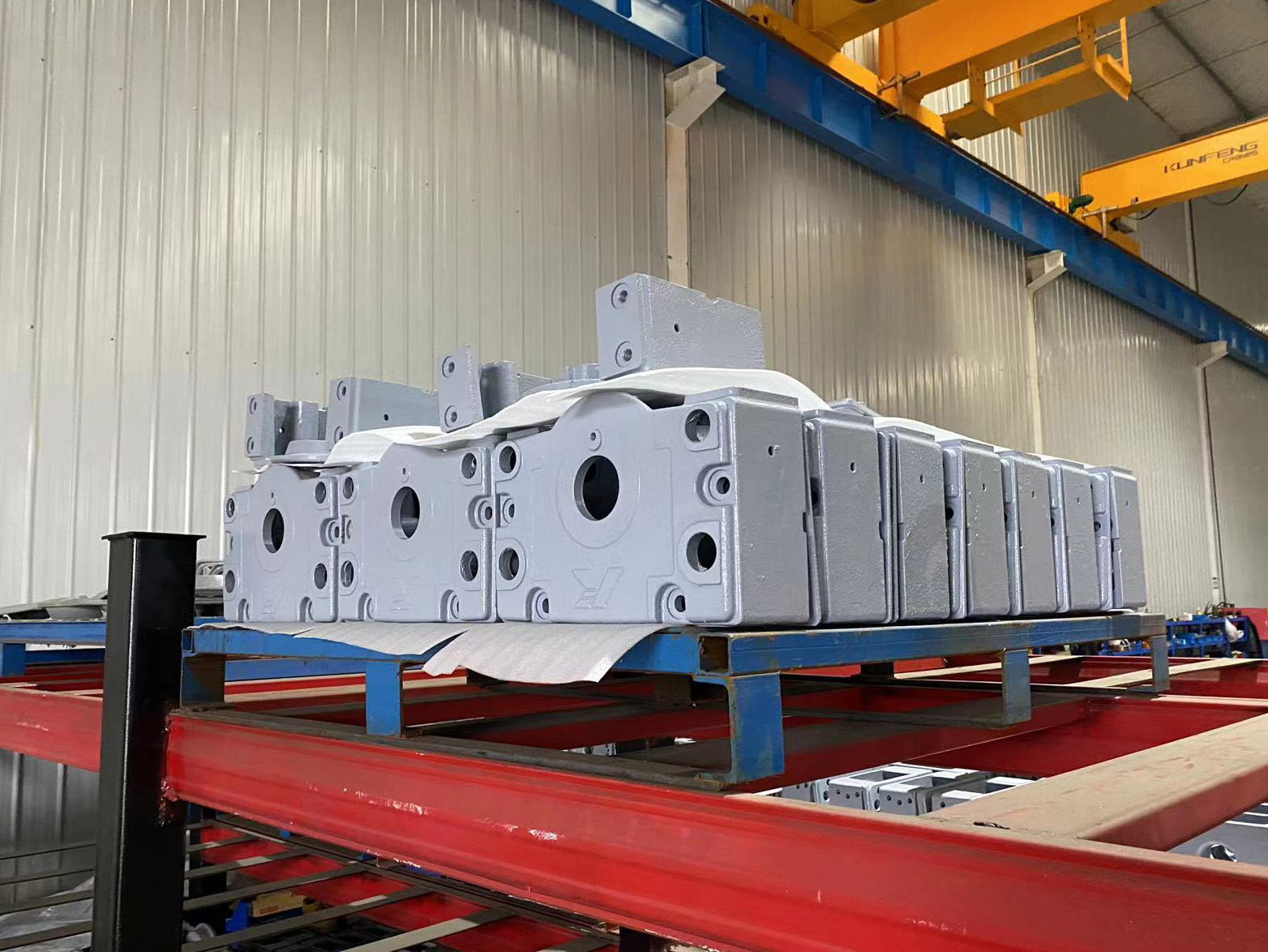

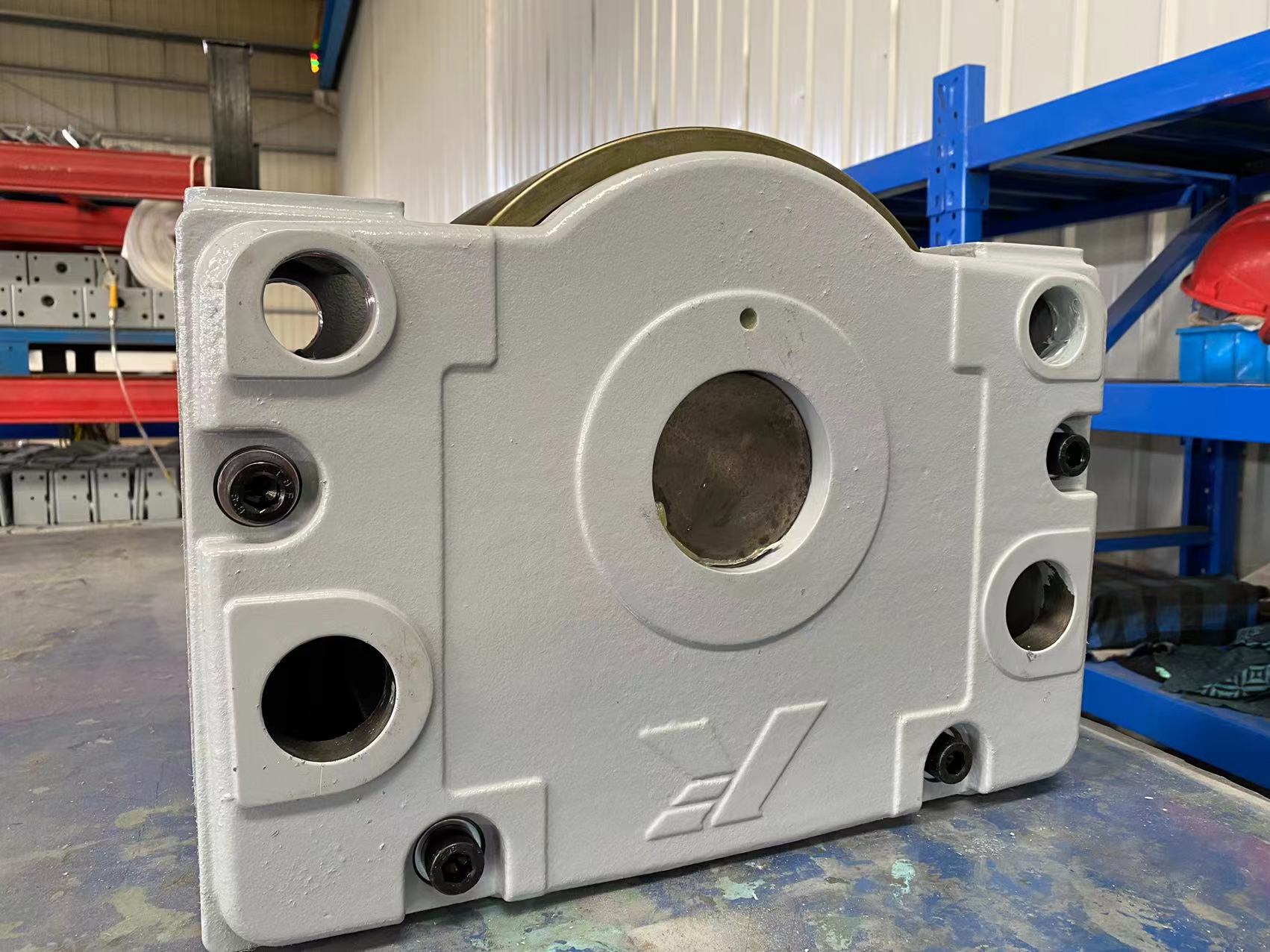

| Система привода колесного блока с мотор-редуктором для крана | Продавец: KunFeng heavy industry (suzhou) co., LTD. (KF CRANE) | Полная система ведомых колес включает в себя колеса, электрический асинхронный двигатель переменн... | |

| Система колесных блоков DRSA | Продавец: KunFeng heavy industry (suzhou) co., LTD. (KF CRANE) | Система колесных блоков KUNFENG® DRSA отличается большой грузоподъемностью при компактных раз... | |

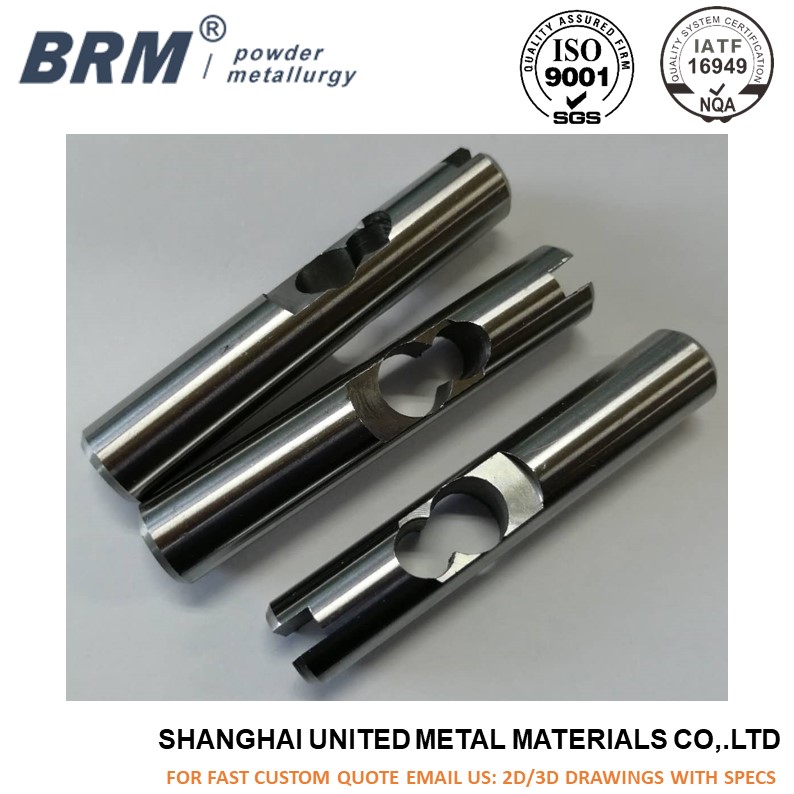

| CNC machining precision steel parts | Продавец: BRM МИМ Технология, Запчасть из Нержавеющей Стали | BRM metal injection molding specializes in Powder Metallurgy for all industries with more than 20... | |

| Precision CNC machining platen of rotor for automotive transmission parts | Продавец: BRM МИМ Технология, Запчасть из Нержавеющей Стали | Product Specifications /Features : Feedstock– Injection molding – De-binding – ... |