Double layer /2 ply corrugated cardboard production line

Double layer /2 ply corrugated cardboard production line

Corrugated cardboard production line

Double layer /2 ply corrugated flute line

Electrical Mill Roll Stand

With the expansion of business scope,Shandong RiNo International Trade Co., Ltd quickly moves forward to the world and becomes an export-oriented company that integrates production and trade, includes paper packaging products, corrugated packaging machinery equipment, packaging product manufacturing equipment & consumablessuch as Corrugated Cardboard Machine, Printing Machine, Folder Gluer Machine, Automatic Die-cutting machine, Iron Wire and many other products,providing a full range of services from product to technical support.

Features

Single Facer corrugated rewinding machine

Features

Paper cutter

Single cutter can do single corrugated cardboard vertically and horizontally cutting. It has change order fast and high cutting precision, working speed fast etc. make litter waste, when changing the order. It suits for the top grade color printing machine. This machine adopts PLC touch screen to design. Through it operator can know all the production status. Adopt variable frequency motor to adjust the speed. Servo control make the cutting length more exactly, making the cutting precision perfectly. (error ±1.5mm).

Lifetime is 6-8 million meters1. Computer aided design is adopted to set the product parameters scientifically, which ensures every piece of our design is economical, reliable and of high quality2. CNC planer type corrugating roll high-precision grinding machine group and additional high-precision grinding machine group are available, which all work for corrugating rolls3. Computerized control to grind the concave rolls4. Selected high quality 48CrMo and 50CrMo alloy steel forged pieces (coating)5. Advanced technology for multilayer processing on high-precision machines6. Advanced heat treatment process is used for quenching and tempering to obtain uniform mechanical properties7. German advanced aquatensid SZ polymer quenching with intermediate frequency, the resultant hardened layer> 7 mm, hardness> HRC58 (HS73-80), uniform hardness with no soft zone8. We use the most advanced high-efficiency atotechheef-25 micro cracks functional chromium plating technology and equipment, to get more rigid, smoother, more wear-resistant hard chrome coatingLifetime is 25% longer than those resulted from ordinary electroplating9. Refurbishment for old corrugating rolls is available

Check before installation

Pre-installation check items:

(1) Cleaning Check the corrugated surface (including surface plating quality).

(2) Cleaning Check the fastening parts (including internal and external threads).

(3) Check the corners of the corrugated roll and the high (the entire roll from both ends to the middle are divided into five or more measurement points. High detection points must be odd, the high data should be symmetrical on both sides). With the corresponding specifications of the diameter micrometer (OD micrometer general mechanical and electrical companies can buy).

(4) check the corrugated roll high. Measured with a needle depth gauge (needle depth dial indicator is not currently available for domestic purchase, or imported from an ordinary depth dial indicator).

(5) Cleaning Check the outer diameter and appearance of the shafts of the corrugated roller, and the outer diameter is measured with the corresponding outer diameter micrometer.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

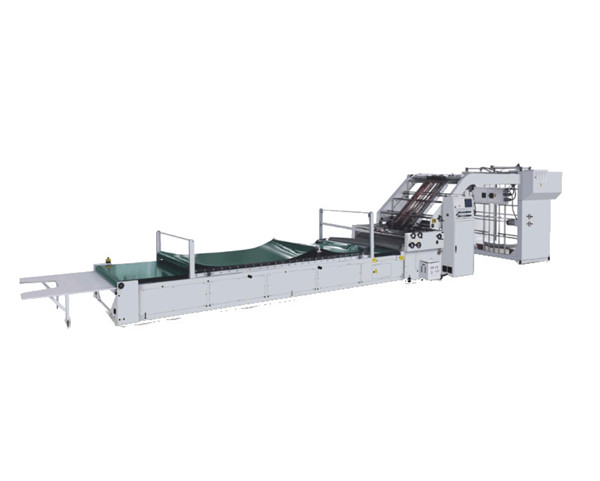

| Automatic Ultra high speed flute laminating machine | Automatic Ultra high speed flute laminating machine Semi-automatic flute laminating machine Automatic flute laminating machine Model ... | |

| Packing Machine-PE | Packing Machine-PE bundling/strapping Machine Machine parameters: The biggest bundle size 1000mm x 800mm The min. bundle s... | |

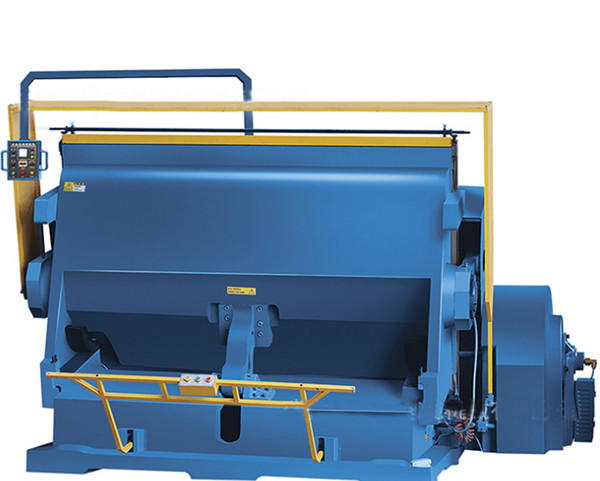

| Manual die-cutting and creasing machine | Manual die-cutting and creasing machine Die-Cutting Machine Manual die-cutting machine Technical parameters: Model Working speed... | |

| Manual die-cutting and creasing machine | Manual die-cutting and creasing machine Die-Cutting Machine Manual die-cutting machine Technical parameters: Model Working speed... | |

| Automatic feeding flexo printer with slotter | Automatic feeding flexo printer with slotter Printing Machine Chain-drive feeder printing machine Model Area of valid printing ... |

Похожие товары

| Full-automatic Spring Packaging Machine ZF-TH700 | Продавец: Shenzhen Zhongfu Packaging Technology Co., Ltd | Mainly used for organ packaging of textured paper. Full-automatic Spring Packaging Machinecan be ... | |

| Full-automatic Pillow Packaging Machine ZF-Z450X ZF-Z600X | Продавец: Shenzhen Zhongfu Packaging Technology Co., Ltd | Z450X Z600X mainly used for single-roll packaging of OPP tape, double-sided tape, foam adhesive, ... | |

| Cylinder Tea Box Shrink Packaging Machine | Продавец: Shenzhen Zhongfu Packaging Technology Co., Ltd | This cylindrical tea box shrink packaging machineis very suitable for heat shrink packaging of cy... | |

| MASTERCUT 106 PER - высекальный пресс Autoplaten | Продавец: Hangzhou siseyin Technology Co., Ltd | Привет!Мы являемся поставщиками печатного оборудования из Китая, предлагаем экспорт машин и обору... | |

| Оборудование для наклеек | Продавец: Hangzhou siseyin Technology Co., Ltd | upply 350 fully automatic high-speed die-cutting machine EVA foam PET protective film multifuncti... |