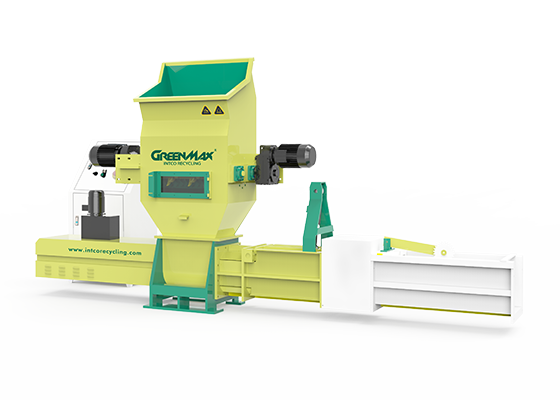

Single Shaft Plastic Waste Shredder

Plastic uniaxial shredder is mainly used for shredding hard plastics, such as: machine head material, trays, shredding of daily miscellaneous hard waste plastics, household appliances, etc. As a professional single-shaft pet bottle shredder manufacturer, we provide high-quality single-shaft plastic shredders to satisfy your needs.

Video of Single Shaft Plastic Waste Shredder

The Single Shaft Plastic Recycling Shredder Machine by GW Recycling Machines is a powerful and efficient solution for shredding plastic waste into smaller pieces for easier transport and recycling. In this video, the features and benefits of the domestic plastic shredder machine are highlighted, including its robust construction, ease of use, and energy efficiency. The shredder machine is capable of handling a wide range of plastic waste materials and is designed to optimize the recycling process. By using this single shaft plastic shredder machine made by our plastic recycling machine company, businesses and organizations can significantly reduce their plastic waste and contribute to a more sustainable future.

Single Shaft Plastic Shredder Applications

The single-shaft shredder has a roller with knives on it. It is driven by hydraulic pressure and forced to feed. The moving knife and the fixed knife are combined to crush the material. The size of the output is controlled by a screen. The single shaft shredder is very versatile, it can process plastic, wood, glass, waste wire, bed sheets, clothes and so on. The single-shaft shredder mainly consists of hydraulic system, reducer, motor, moving knife, fixed knife, knife roller and so on.

Domestic Plastic Shredder Features

This product can be used to shred bulk materials, baskets, pipes, plates, wood, tires, scrap metal drums and large rolls of film, which are difficult to be shredded by shredders;

Super Thick plate precision machining combination structure frame, large-angle hexagonal column powerful shaft, large-diameter solid input hopper, allowing you to safely input large-scale raw materials;

Design and process unique rotary cutters in terms of thickness, shape, arrangement sequence, etc. Shearing Strong force, sharp blade, high crushing efficiency;

Low speed operation, low noise, less dust; 5. The knife is made of special alloy steel.

Domestic Plastic Shredder Working Principle

The waste shredder belongs to the technical field of waste treatment equipment, including a box body, two main shafts arranged side by side and parallel in the box body, several blade groups fixed on the main shaft and arranged at intervals, and a coupling shaft sequentially connected to the transmission end of the main shaft It is characterized in that each blade group is composed of two superimposed blades, gaskets are arranged between adjacent blade groups to space the blade groups from each other, and the blade groups on the two main shafts are arranged alternately. It can tear rebar of about φ8 specification and a thin plate of about 5mm, which greatly increases the shredding range of the shredder's material source. In addition to plastic and rubber products, household electrical appliances and articles are basically within the scope of shredding, the floor space is small and the production cost is low.

The plastic shredder is a kind of solid waste volume reduction mechanical environmental protection shredder equipment, which is used to shred high-density polyethylene (HDPE) plastic products and materials, which is beneficial to plastic recycling and recycled plastic particles. For example mineral water bottles, PET bottles, motor oil bottles, gasoline bottles, plastic barrels, etc.

Single Shaft Plastic Waste Shredder Specification

|

Power: |

22KW |

|

Diameter of Mesh: |

16mm |

|

Number of Moving knife: |

6 |

|

Number of Fixed knife: |

2 |

|

Blade Material: |

SKD-11 |

|

Size of Feed Port: |

610*500mm |

|

Length of Spindle: |

900mm |

|

Brand of Bearing |

SKF brand |

Now the pet bottle shredder priceis reasonable, if you have needs, please contact us.

We can offer sorts of waste plastic recycling equipmentfor sale, if you want to buy high quality waste plastic bottle recycling machine, please leave us a message.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Plastic Film Crusher | The plastic film crusherproduced by our plastic film crusher factoryis mainly used for the crushing of various film waste plastics, such as: domest... | |

| Mixed Plastic Recycling Extrusion & Injection Molding Machine | The equipment we have developed includes: one-step extrusion molding equipment for mixed waste plastic films; two-step extrusion molding equipment ... | |

| Products | Waste Plastic Recycling Machine Guowang Eco Technology Specializes in Plastic & Textile Recycling Machine Guowang has been paying attention to ... | |

| Plastic Pallet Crushing and Shredding Machine | Pallet Crusher for Sale The waste plastic pallet shredding-shredding machine is a supporting product specially developed for pallet shredding, cre... | |

| Hydraulic Compression Machine | Hydraulic moulding press is the main equipment for compression molding. According to the frame structure, hydraulic plastic moulding machine is div... |

Похожие товары

| PET bottle recycling machine And Squeezer POSEIDON C900 | Продавец: Intco Recycling GREENMAX | PET bottle recycling machinePoseidon series specializes in de-watering and compacting beverage bo... | |

| GREENMAX PET bottle recycling machine P-C350 | Продавец: Intco Recycling GREENMAX | PET bottle recycling machinePoseidon series specializes in de-watering and compacting beverage bo... | |

| Bottle Dewatering And Squeezer POSEIDON C200 | Продавец: Intco Recycling GREENMAX | PET bottle recycling machine Poseidon series specializes in de-watering and compacting beverage b... | |

| GreenMax Foam Compactor Z-C100 | Продавец: Intco Recycling GREENMAX | GreenMax Zeus C100 foam compactor isspecialized in waste foam recycling by extruding foam based o... | |

| GREENMAX EPS crusher for beads | Продавец: Intco Recycling GREENMAX | GREENMAX EPS beads crusher is a recycling equipment, especially for recycling EPS/polystyrene. Di... |