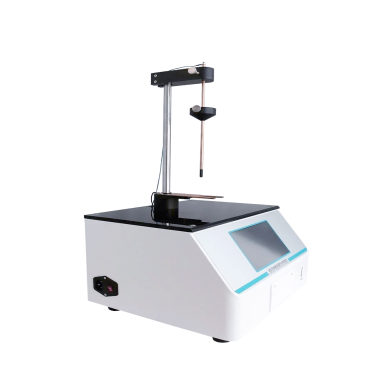

ink abrasion tester / Ink Abrasion Resistance Tester Ink Rub Tester

Ink abrasion testerPrinciple:

To be ground layer and Friction Paper of the Ink Abrasion tester samples, under the action of the load friction body, rubbing each other at a predetermined speed. Make measuring the reducing amount of the density before and after the friction, or decrease the amount of coating thickness, to determine the wear resistance with the ink layer or coating.

Ink Abrasion tester with Microcomputer control, LCD dynamic display, mechatronics principle, rubbing test set. Before the test, the test requirements of the standard, the number of friction or custom operator input control system, the test can achieve automatic control, and after the end of each test beep.

Control system with power and memory function, which is, after each power cycle, keeping parameters state before the power was last entered. Ink wear tester actuator using high-precision micro-motor gear driven friction body friction linear reciprocating motion

Features:

Microcomputer control, LCD blue large LCD dynamic display, film inching operation panel;

Input Test parameters on keyboard, and also with the power and memory;

The exact implementation of national standards, compatible with international standards;

Control Solutions for printed ink poor wear resistance; low rub resistance, easy to fall off and so on;

Test, effective control of the production process, to avoid return losses due to poor quality.

Compatible with PS version of the photosensitive layer of the abrasion resistance test, make analysis and forecast PS version of the anti-Indian forces

Technical Parameters:

Power supply: AC220V ± 10% 2A 50HZ;

The friction velocity: (21. 43. 85. 106) r / min

Measuring range: (1 to 9999) times;

Friction load: GB: 20N;

ASTM: 0.9kg (2Lb)

Friction distance: 60 mm

machine interface: 3.1 "@ 128 × 64 dot matrix LCD screen (blue), English menu;

Working environment: temperature (20 ± 10) ° C;

Humidity <85%;

Dimensions: 335 × 295 × 295 mm;

Product Weight: about 22 kg;

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| AT1000 Abrasion Resistance Tester | Device description The at1000 wear tester has been used around the world since 1970 and is ideal for comparison and quality control of platelet-sh... | |

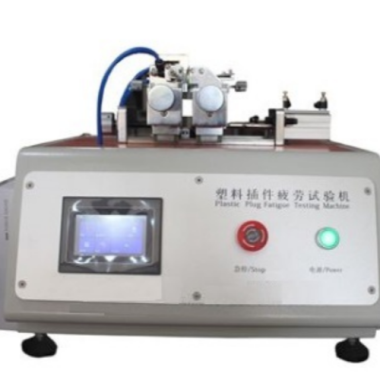

| Bag Plastic Buckle Durability Tester - Standard | Product Introduction: It is mainly used to test the service life of plastic plug-ins in luggage accessories. Technical standard: QBT 5247-2018 ... | |

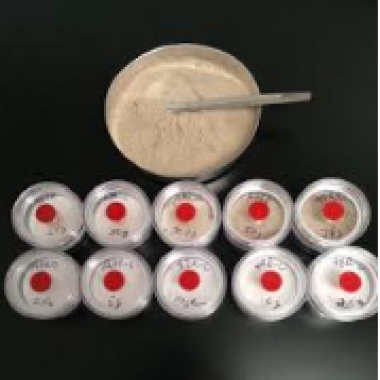

| Fuel Contamination Test Dust | Product Introduction: Particle Technology UK offers a full range of materials used in fuel contamination tests, which are used to test the reliabi... | |

| Veslic Multi-Functional Material Tester | VESLIC Tester - Precision for Leather Abrasion Resistance | Standard ISO 13934-1(Tensile Properties of Fabrics) ASTM D624(Tear Strength of Rubber and Elastomers) AATCC 135(Dimensional Changes in Textiles ... | |

| Prefilled Syringe Plunger Force Tester | The Push - force Tester for Prefilled Syringes is widely used in the medical device industry, mainly for testing the push - force performance of pr... |

Похожие товары

| Bottle Wall and Bottom Thickness Tester | Продавец: Standard Group (Hong Kong) Limited | The wall and bottom thickness tester for bottles is a measuring instrument widely used in the pha... | |

| Pinhole Tester / Pinhole Testing Equipment | Продавец: Standard Group (Hong Kong) Limited | The pinhole tester for aluminum foil is a device specifically used to detect micro - pinholes in ... | |

| Cork Puncture and Chip Detection Instrument | Продавец: Standard Group (Hong Kong) Limited | The rubber stopper puncture debris detector is a device specifically used to detect the number of... | |

| Aluminum Ointment Tube Toughness Tester | Продавец: Standard Group (Hong Kong) Limited | The ductility tester for aluminum tubes is a device specifically used to detect the ductility ind... | |

| Vacuum leak tester / Vacuum leak instrument | Продавец: Standard Group (Hong Kong) Limited | Vacuum Decay Leak Tester specializes in the detection of leaks in ampoules, vials, injection bott... |