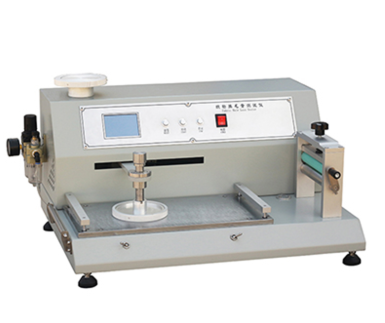

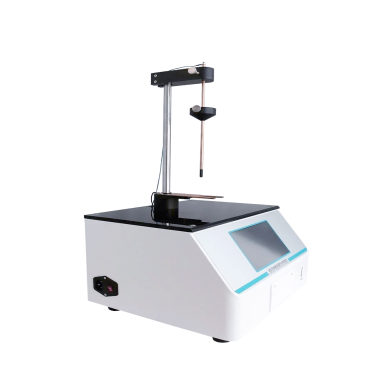

Hot Tack Tester / Heat Seal Tester

Standards

GB/T 34445 - 2017 ASTM F2029

Main Uses

The hot - tack tensile tester is an instrument specifically designed to test the hot - tacking and heat - sealing properties of packaging materials. Its main uses include, but are not limited to:

- Evaluating the Heat - Sealing Performance of Packaging Materials: By simulating the heat - sealing conditions of packaging production lines, it tests the strength of materials after heat - sealing, ensuring that packaging materials can maintain their integrity during transportation and storage.

- Quality Control: During the production of packaging materials, regular testing with a hot - tack tensile tester can promptly identify production issues, ensuring stable and reliable product quality.

- Material R & D: In the process of developing new materials, the hot - tack tensile tester can be used to evaluate the impact of different formulations and processes on the heat - sealing performance of materials, providing a basis for material optimization.

- Applications in Multiple Fields: In addition to packaging materials, the hot - tack tensile tester can also be used to test the peeling and breaking properties of soft materials such as adhesives, adhesive tapes, self - adhesive labels, and paper, providing technical support for the application of these materials.

Technical Parameters

- Heat - Sealing Pressure: Adjustable from 0.05 MPa to 0.7 MPa, used to simulate different heat - sealing conditions.

- Heat - Sealing Time: Adjustable from 0.1s to 999.9s, ensuring that the heat - sealing process reaches a stable state.

- Hot - Tack Time: Adjustable from 0.1s to 999.9s, used to evaluate the performance of materials during the hot - tacking process. -

Temperature Control: Using digital P.I.D temperature - control technology, it can quickly reach the preset temperature and maintain the temperature stable.

- Force Range: Multiple ranges are available, such as 0 - 200N (some devices may have a larger range).

- Accuracy: Generally level 1 or higher, ensuring the accuracy of measurement results.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Temperature and Humidity Test Chamber / Temperature & Humidity Tester | Features and Benefits 1.Wide Temperature Range:Selectable from -20°C, -40°C, -60°C, or -70°C up to +150°C, with a high-efficie... | |

| Stainless Steel Envirotronics Chamber | Useful and durability | Environmental Test Chamber is designed for laboratory experiments, product reliability testing, and programmable controls, providing a wide range o... | |

| Stapler Blade Sharpness Tester YY/T 1797 | The Sharpness Tester for Stapler Blades plays a crucial role in the medical device field. The following is a detailed introduction to its complianc... | |

| Schopper Abrasion Tester | Standards DIN 53863. Part 2: Abrasion test methods for textile fabrics (rotary abrasion test). GME Standard 60345 & GMW Standard 3283: Indust... | |

| Fabric Fiber Shedding Degree Tester (Friction Method) / Fabric Shedding Test Machine | Instrument Testing Principle Lay the specimen flat and fix it on the holder. Make the wet abrasive attached to the friction head perform reciproca... |

Похожие товары

| Bottle Wall and Bottom Thickness Tester | Продавец: Standard Group (Hong Kong) Limited | The wall and bottom thickness tester for bottles is a measuring instrument widely used in the pha... | |

| Pinhole Tester / Pinhole Testing Equipment | Продавец: Standard Group (Hong Kong) Limited | The pinhole tester for aluminum foil is a device specifically used to detect micro - pinholes in ... | |

| Cork Puncture and Chip Detection Instrument | Продавец: Standard Group (Hong Kong) Limited | The rubber stopper puncture debris detector is a device specifically used to detect the number of... | |

| Aluminum Ointment Tube Toughness Tester | Продавец: Standard Group (Hong Kong) Limited | The ductility tester for aluminum tubes is a device specifically used to detect the ductility ind... | |

| Vacuum leak tester / Vacuum leak instrument | Продавец: Standard Group (Hong Kong) Limited | Vacuum Decay Leak Tester specializes in the detection of leaks in ampoules, vials, injection bott... |