Quality Analysis Of Iron Casting

Quality Analysis Of Iron Casting

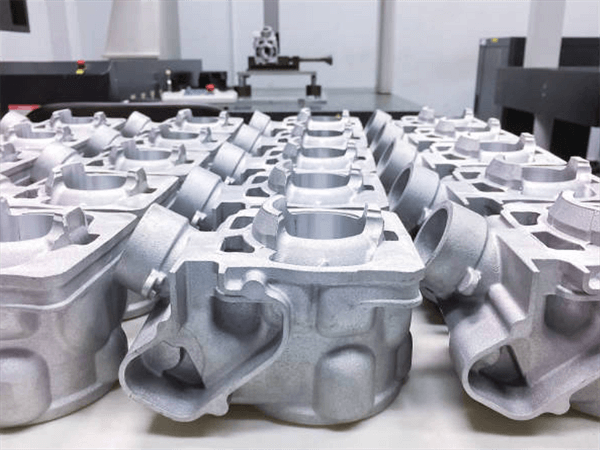

Iron castings such asfor industrial development of China's major industry development is very rapid in recent years, mainly for castings porous structure, the ash in the process of origin are the corresponding technical requirements, castings with the requirements of the production process parameters mainly, hot metal melting temperature of main must control the best temperature is between 1500 ~ 1550 ℃, 1530 ℃, so we can ensure that the molten iron of high purity, thus removing the hereditary of graphite iron cast. According to the general casting wall thickness to determine the automobile castings, for example, according to the shape of the casting wall thickness is different, generally in the range of 1400 ~ 1440 ℃. Iron casting should guarantee in the inoculation process, make the inoculant quickly dissolved in molten iron, and exist in the microcosmic concentration difference, guarantee in the subsequent cooling solidification crystallization of enough in the process of crystallization core, general processing should be controlled at about 14500 ℃ is preferred.

The coating of iron castings such asrequires that due to the heavy weight of castings, large wall thickness, heat concentration, and long time of liquid iron, the surface of iron castings is easy to oxidize and produce permeable sticky sand, and the requirements of sand cleaning time and cleanliness are increasingly high, and the requirements of gas generation and cost are increasingly low. It is because of this situation that higher requirements are put forward for casting and coating. The general situation of castings is easy to oxidize and permeate with sand. The coating of grey castings requires that the grey castings should have heavy weight, thick wall, concentrated heat and long time of liquid connection between iron and liquid. Sand cleaning time, cleanliness and other requirements are getting higher and higher, gas output, old requirements are getting lower and lower. It is because of this situation that higher requirements are put forward for casting and coating. The coating carrier is the dispersion medium of refractory powder. Generally there are two categories: water-based and alcohol-based, which can be selected according to the actual situation of the production site and old consideration; The most effective suspension agent is multivariate compound.

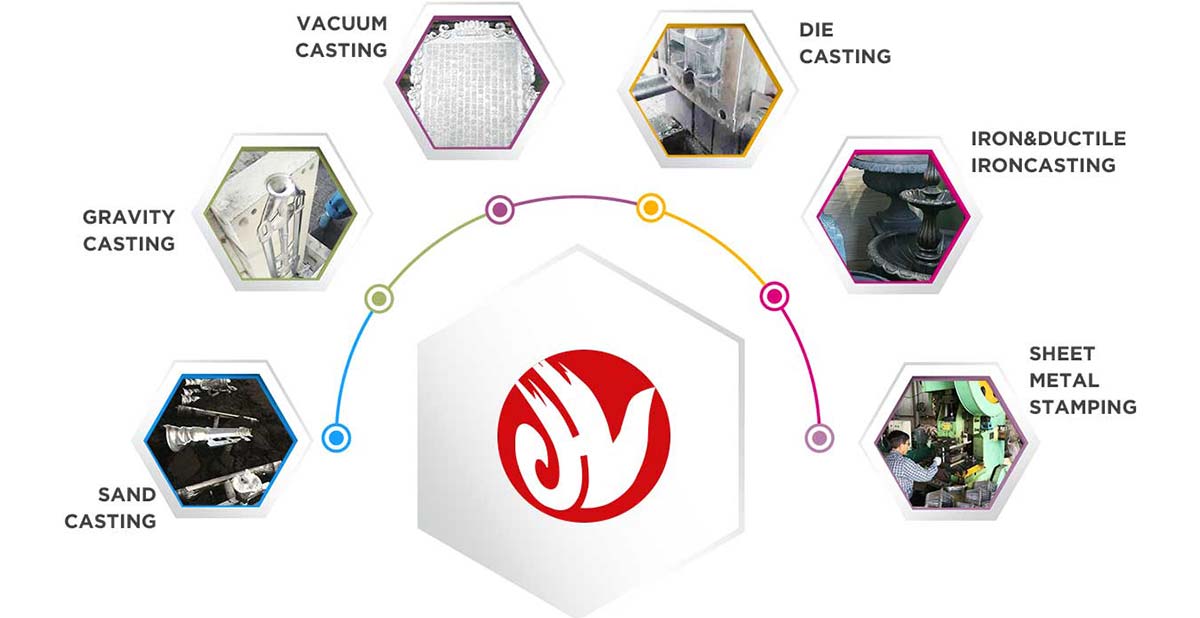

Located in Liaoning province in northeastern China, LianJiang Metals Company have specialized in aluminum and iron casting production since 1997. We are an OEM partnership that manufactures and iron parts for clients all over the world and in different industries such as , patio furniture & company.

With over 20 years of casting work experience and expertise, we offer a full range of casting processes including:sand casting,gravity casting,die-casting,vacuum casting

If you want to know more about the product, please .

MoreProductsPlease .

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Fireplace Art Shared By The Fireplace Casting Manufacturer | Fireplace Art Shared By The Fireplace Casting Manufacturer Fireplace Art Shared By The Fireplace Casting Manufacturer Manufacturer shares that in t... | |

| Fluidity Of Cast Iron And Its Test Methods | Fluidity Of Cast Iron And Its Test Methods The fluidity of nodular cast iron and gray cast iron is the filling and casting capacity of cast iron in... | |

| CASTING SOLUTIONS, Cast Aluminum and Iron Parts, Garden Decoration Cast Part | CASTING SOLUTIONS,Cast Aluminum and Iron Parts,Garden Decoration Cast Part Located in Liaoning province in northeastern China, LianJiang Metals Com... | |

| Processing procedures and sand cleaning methods for aluminum castings | Processing procedures and sand cleaning methods for aluminum castings shares that aluminum casting is a kind of pressure casting parts, is the use ... | |

| Garden Decoration, Garden Decoration Aluminum Casting, Cast Aluminum Garden Decoration, Garden Decoration Casting Design | Garden Decoration,Garden Decoration Aluminum Casting,Cast Aluminum Garden Decoration, Garden Decoration Casting Design ALUMINUMCASTING ITEM No: Gar... |

Похожие товары

| Custom Gravity Cast Service | Продавец: Ньюэй Пресижн Воркс Лтд. | Изучите различия между гравитационным литьем и другими методами литья, чтобы определить лучший ... | |

| Metal Injection Molding Service for MIM Parts Manufacturing | Продавец: Ньюэй Пресижн Воркс Лтд. | Neway — первоклассный поставщик услуг по литью металлов под давлением для изготовлени... | |

| THE 24th CHINA(GUANGZHOU) INTERNATIONAL DIE CASTING,FOUNDRY & INDUSTRIAL FURNACE EXHIBITION | Продавец: GUANGZHOU JULANG EXHIBITION DESIGN CO., LTD | 2024China(Guangzhou)Int’l Metal & Metallurgy Exhibition THE 24th CHINA... | |

| Hydraulic Steering Control Units | Продавец: Hebei Golden-hammer forgings co., ltd | The hydraulic steering gear is a hydraulic power steering type between the steering wheel and the... | |

| Hydraulic Motor | Продавец: Hebei Golden-hammer forgings co., ltd | The hydraulic motor is an actuator of the hydraulic system that converts the liquid pressure ener... |