China Diamond Segment Suppliers and Manufacturers

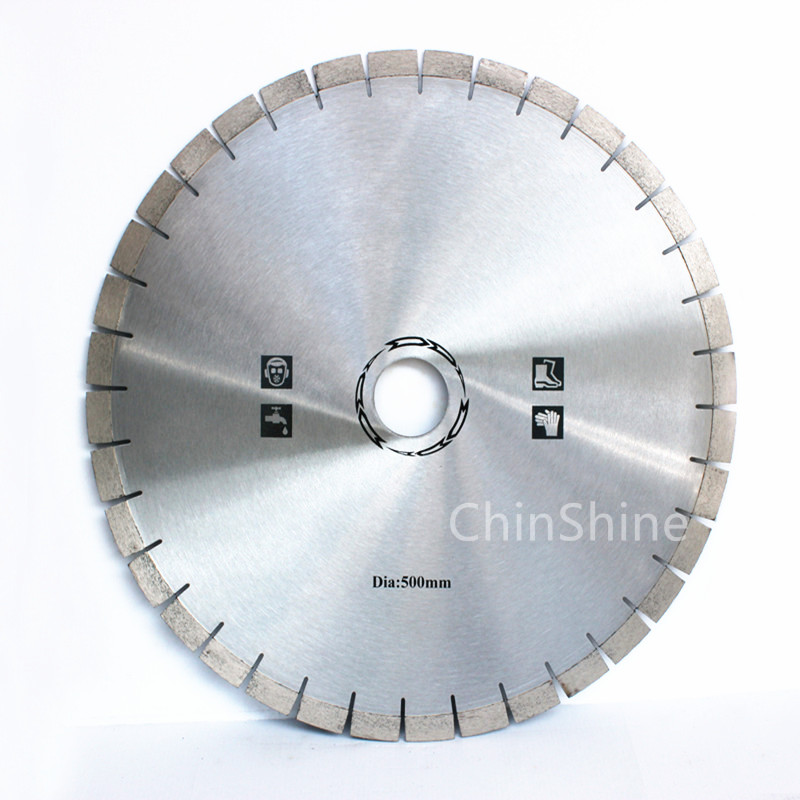

Application:Green concrete, cured concrete, asphalt.Technology:Laser Welded or Silver BrazedSegment Type: Roof segment

Diamond segments have excellent wear resistance and long life, can significantly improve processing efficiency, reduce material loss, and are an indispensable and important tool in modern industrial production. According to different application requirements, can be designed into a variety of shapes and specifications, such as discs, bars, etc., and diamond particles of different sizes and concentrations can be selected according to the hardness and characteristics of the material to meet diverse processing requirements.

What is a Diamond Segment?

refer to a tool component formed by fixing artificial or natural diamond particles on a metal matrix through a special process. These diamond particles act as cutting edges and can efficiently cut hard materials under high-speed rotation.

Application Areas

- Stone processing: In the cutting of natural stones such as marble and granite, diamond segments can achieve fast and smooth cutting effects and reduce material loss.

- Concrete construction: Whether it is a new construction project or the renovation of an old building, a saw blade using a diamond segment can be used for precise cutting on building materials such as concrete and masonry.

- Metal processing: For some metal materials with higher hardness, traditional tools are often difficult to handle, while diamond segments can provide a more effective solution.

- High efficiency: Diamond is one of the hardest substances in nature, so diamond segments have very high cutting speeds and long service life.

- Accuracy: Through precision manufacturing technology, it is possible to achieve fine processing of materials and meet high standards of processing requirements.

- Strong adaptability: According to different material properties and processing requirements, different specifications and types of cutter heads can be customized, suitable for a variety of operating environments.

Advantages of our diamond segments

How to Choose ADiamond Segment That Suits You?

As a very professional , we responsibly tell you that choosing the right diamond abrasive segment is crucial to ensuring processing quality and efficiency. Here are some key factors and steps to help you choose the diamond abrasive segment that best suits your needs:

First, determine the specific type of work you need to do, such as stone cutting, concrete cutting, metal processing, or other special material processing. Different application scenarios have different requirements for diamond abrasive segments.

lHardness: Understand the hardness of the material to be processed. For harder materials, such as granite or certain metal alloys, choose diamond grits that are more wear-resistant.

lBrittleness: For brittle materials, such as marble or ceramics, you may need to choose abrasive segments with finer grit and gentler cutting forces to avoid cracking.

lWater cooling/dry cutting: Determine whether your process will use water cooling or dry cutting. Water cooling helps to extend the life of the abrasive segment and reduce heat buildup, while dry cutting requires the abrasive segment to have better heat dissipation performance.

lDepth of cut: If deep cuts are required, choose thicker and stronger abrasive segments.

lGrit size: Grit size determines the fineness of the cut. Coarse grit is suitable for quickly removing large amounts of material, while fine grit is suitable for precision cutting and flat grinding.

lConcentration: The concentration of diamond grit (i.e. the amount of diamond per cubic centimeter) affects the durability and cutting efficiency of the abrasive segment. High concentration is suitable for long-term continuous operation, while low concentration is suitable for short-term or intermittent use.

Choose high-quality products from well-known brands, which usually have better technical support and after-sales service. Check the user reviews and technical parameters of the product, and consult professionals if necessary.

Although high-quality diamond abrasive segments have a higher initial investment, they may be more economical in the long run considering their long life and high efficiency. Consider factors such as price, performance and service life to make a reasonable choice.

Ensure that the selected product complies with relevant safety standards and industry specifications, read the product manual carefully before use, and operate according to the recommended operating methods to ensure personnel safety and normal operation of equipment.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Diamond Wire Saw Rope For Reinforced Concrete Cutting | As it is always known, diamond wires can help you renovate, demolish and dismantle houses, bridges and large buildings. ChinShine as a professional... | |

| Оптовые поставки лазерносварной алмазной цепи для бензопилы по бетону | Компания ChinShine, производитель алмазных пильных дисков, предлагает полный ассортимент цепных пил с алмазными сегментами для резки бетона, кирпич... | |

| Diamond Vacuum Brazed Wire Saw Rope For Construction Reinforced Concrete | Vacuum Brazed Wire: *44 beads per meter *Bead diameter 10.5/11.5mm *Segment Type: Vacuum brazed/ Granite diamond wire *Lengths: 50m /100m *Con... | |

| High quality China Diamond Saw Blade Suppliers Pricelist | Crafted with advanced technology, Chinadiamond saw blades feature durable diamond segments that ensure sharp, precise cuts in materials like concre... | |

| Laser Welding Diamond Chain For Concrete Chainsaw | ChinShine, a diamond cutting blade manufacturer a full line of diamond chain saws for cutting concrete, brick, and natural stone. ChinShine’s... |

Похожие товары

| diamond grit ceramic oscillating multi-tool blade | Продавец: Hailian Saw Blade Technology Co., Ltd. | This diamond grit ceramic oscillating multi-tool blade is specifically designed for cutting throu... | |

| Reinforced Concrete Diamond Wall Saw Blade Segment U-Arix | Продавец: Xiamen ChinShine Industry and Trade Corporation | Product Parameter Abrasive: Industrial diamond Segment Size: 40*4.8*12mm Activities/Uses: Wet ... | |

| Arix Diamond Wall Saw Blade | Продавец: Xiamen ChinShine Industry and Trade Corporation | Product Introduction The wall saw blade is welded by German Dr. Fritsch's full-automatic laser w... | |

| U-Slot Wall Saw Blade | Продавец: Xiamen ChinShine Industry and Trade Corporation | The wall saw blade is welded by German Dr. Fritsch's full-automatic laser welding production line... | |

| 800mm Diamond Arix Wall Saw Blades for Concrete Fast Cutting | Продавец: Xiamen ChinShine Industry and Trade Corporation | Product Parameter Blade Core thickness: 3.2 or 3.5mm Segment thickness: 4.5/4.8mm/5.0mm Segmen... |