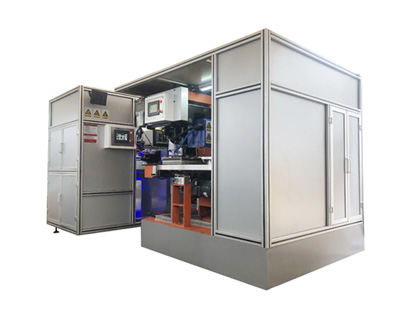

PAPER DRUM STAINLESS STEEL BELT CRIMPING WELDER

This equipment is designed for crimping and forming after welding of paper drum stainless steel rings. It is connected with our automatic laser welding equipment via a conveyor belt and then rotated and crimped at high speed. The mechanized action adopts servo digital control, which greatly shortens the product replacement time. This product must be used with our fully automatic laser welding machine to form a fully automatic production line.

Get Paper Drum Stainless Steel Belt Crimpi

THE PARAMETER OF PAPER DRUM STAINLESS STEEL BELT CRIMPING WELDER

|

Input voltage |

Enter the frequency |

Product diameter |

Product thickness |

Product width |

Dimensions |

|

3*380V |

50HZ |

120~650mm |

<0.8mm |

12~80mm |

1700*1600*1800mm |

The Advantages Of Paper Drum Stainless Steel Belt Crimping Welder

The equipment is produced by a conveyor belt combined with a laser welding tool, which changes the previous manual crimping. The equipment adopts information exchange control, which is completely unified with the previous process, and the subsequent process can be added at any time to achieve unified control. The crimping method is inverted and does not require any lubricant.

The Application Of Paper Drum Stainless Steel Belt Crimping Welder

This equipment is a special equipment for the crimping process after the paper drumstainless steel is welded. After laser seamless welding, the hemming process is automatically carried out through the conveyor belt to reduce labor costs. The mechanical action adopts servo digital control, which greatly shortens the product replacement time. The device is beautiful in appearance design, simple in operation, easy to learn and understand.

Other Notes Of Paper Drum Stainless Steel Belt Crimping Welder

Paper drum stainless steel belt crimping welder Main Characteristics

1

Beautiful appearance design, simple operation, easy to learn and understand.

2

Reducing labor can save costs and reduce scrap rate.

3

The mechanical action adopts servo digital control to shorten the adjustment time.

4

The way of crimping is upside down, no need to add any lubricant.

5

It can be used together with the laser welding equipment produced by our company to realize a fully automatic production line.

6

Adopt information exchange control to achieve unified control with the previous process.

Now the price of beader crimper combination machineand bead and crimp machineis reasonable, if you are interested, please leave us a message.

Send product request

Other supplier products

| MESH BASKET STAINLESS STEEL BELT AUTOMATIC PRODUCTION LINE | The equipment adopts advanced laser continuous welding technology, through the welding machine fixture feeding - cutting - welding, mechanical arm ... | |

| PAPER DRUM STAINLESS STEEL BELT CRIMPING WELDER | This equipment is designed for crimping and forming after welding of paper drum stainless steel rings. It is connected with our automatic laser wel... | |

| AUTOMATIC WELDING MACHINE FOR DUST COVER OF AUTOMOBILE BRAKE | AUTOMATIC WELDING MACHINE FOR DUST COVER OF AUTOMOBILE BRAKE The equipment is a special 1500 laser welding systemdesigned for the brake dust cover... | |

| LASER SEAM WELDING | Laser seam weldingis a superior welding technique that provides precise and efficient joining of two metal sheets without the need for a filler or ... | |

| AUTOMATIC PRODUCTION LINE OF STAINLESS STEEL BELT FOR POT COVER | The stainless steel belt automatic production line is an automatic welding and forming production line developed for the G-ring of the kitchen glas... |

Same products

| XD-MAX Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |