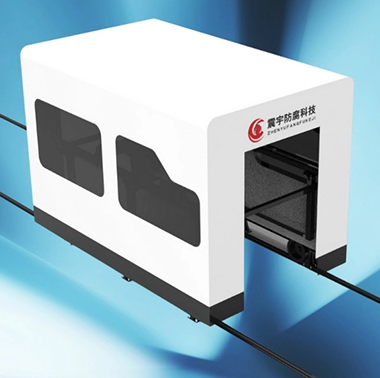

Wind Turbine Coating and Painting Machine Manufacturer

Zhenyu Technology's automatic wind turbine paintingand coating machine equipment, which is mainly composed of a spraying host, touch screen operation part and wireless operation part, controls the operation of the equipment through software. Wind turbine coating and painting machines can automatically spray different types of wind power towers, saving labor and paint, and accurately controlling the film thickness. We also offer painting wind turbine blades, and protective coating for turbine blades, for more information, please contact Zhenyu Technology automated spray coating systems supplier.

Types of Wind Turbine Coating and Painting Machine

Zhenyu Technologyautomatic wind turbine coating and painting machine equipment, which is divided into onshore equipment, offshore equipment, and various models. Wind turbine coating and painting machine mainly consists of a spraying host, touch screen operation part and wireless operation part, and controls the operation of the equipment through software.

Onshore Wind Turbine Coating Machine

Zhenyu Technology onshore wind energy tower computerized spraying equipment. The gear is divided into internal wall gear and outer wall equipment. The internal wall tools is usually composed of a spraying host, a contact display screen operation section and a wi-fi operation part.

Offshore Wind Turbine Coating Machine

A machine used to coat offshore wind turbines with protective layers of paint or other materials to limit corrosion.

Difference Between Onshore and Offshore Wind Turbine Coating and Painting Machines

Difference Between Onshore and Offshore Wind Turbine Coating Machines

Onshore wind turbine coating and painting machines are designed to provide a protective coating to the exposed components of the wind turbine. Wind turbine coating and painting machines are typically used to coat the nacelle, blades, and towers of the turbine. The coating protects the metal or composite materials from corrosion and other environmental factors.

01

Operating Conditions

Onshore wind turbine coating and painting machines are usually used in a temperate environment, while offshore wind turbine coating and painting machines are designed to withstand harsh weather conditions such as saltwater corrosion or extreme temperatures.

02

Maintenance

Onshore wind turbine coating and painting machines are more accessible for maintenance and repairs, while offshore wind turbine coating and painting machines are more difficult to access due to their location.

Why Choose Zhenyu Wind Turbine Coating Machine

Since its establishment, Zhenyu Technology automated spray coating systems supplier has been focusing on wind turbine coating and painting machines research and development, in addition, our company has also introduced a number of theories rich, high-level talents with excellent technology, establishing a sound R & D team and management system.

At present, Zhenyu Technology automatic spray machine factoryhas cooperated with several domestic universities, and several scientific research teams and units for online signing and programming. We have established a long-term cooperative relationship, improving the company's R & D strength. At the same time, the company has established a high-standard R & D laboratory and assembled a large number of advanced professionals, the company relies on perfect management level and strong R & D strength. With rich cooperation experience and good after-sales service, it has won extensive support and trust from customers.

Zhenyu Technology automated spray coating systems supplier has applied for more than 30 patents, including 3 invention patents and 12 utility model patents, 11 soft works. And won the title of Ji'nan high-tech enterprise in 2021. It has passed ISO quality system certification and occupational health and safety system certification, environmental management system certification. Our mission is to "liberate the paint spraying industry and keep away from spraying occupational hazards", take "being the leader in the field of automatic spraying" as the goal, and follow the principle of "quality first, service first". Sincerely look forward to cooperating with you

Wind Turbine Coating and Painting Machine FAQ

Can the spraying efficiency of wind turbine coating and painting machine be improved?

After the successful development of the wind turbine coating and painting machine, 2 equipment operators will replace the original 1 skilled paint sprayer and 1 auxiliary worker. The spray gun of the equipment adopts double gun design, and the spray range can reach 70cm, which greatly improves the spraying construction efficiency. It only takes about 3 hours to manually spray the inner wall and outer wall of a section of tower, and 1 hour to automatically spray.

How about the wind turbine coating and painting machine spraying quality?

Compared with ordinary manual painting, the overall paint film thickness of the wind turbine coating and painting machine is uniform and accurate. The thickness of a single paint film can be designed by itself. The components have a good film appearance, less surface paint mist and high paint finish, which greatly saves the polishing and roughening workload of auxiliary workers for paint mist, sagging and other defects, and greatly saves labor costs in the overall production project.

Is the wind turbine coating and painting machine easy to operate and learn?

The operating wind turbine coating and painting machine is controlled by the touch screen. The automated spray coating systems can be realized by inputting the corresponding data such as the tower specification (length and diameter at both ends), the paint film thickness and the paint fixed component content according to the prompts on the touch screen. Moreover, the paint film thickness can be arbitrarily designed, and the program automatically operates according to the corresponding parameters. The paint spraying process quality is not affected by objective factors such as the painter's water, and the paint quality can be controlled.

Whether the wind turbine coating and painting machine complies with environmental protection standards?

The whole set of wind turbine coating and painting machine adopts software control to accurately control the spray distance, spray speed, spray angle and other parameters between the spray gun nozzle and the components, and achieve the best cooperation between them, so that the paint mist generated in the spray process can be greatly reduced, thus reducing the operation and maintenance costs of the environmental protection waste gas treatment equipment.

Send product request

Other supplier products

| High Quality Automatic Spray Coating Machine Features and Benefits | ZHENYU supplies high-quality automatic spray coating machinebenefits for our clients: The spray automatic machineis easy to operate, and the con... | |

| Wind Turbine Coating and Painting Machine Manufacturer | Zhenyu Technology's automatic wind turbine paintingand coating machine equipment, which is mainly composed of a spraying host, touch screen operati... | |

| Automatic Paint Spraying Line | Automatic Paint Spraying Line Steel structure buildings are widely used in various industries. Because of their complex shapes, Most of the anti-c... | |

| Steel Structure Automatic Spray Painting Machine Equipment Supplier | Zhenyu Technology's automatic spray painting machine equipment, the spraying construction of H-type, circular, box type, column, and beam can be re... | |

| Offshore Wind Turbine Coating Machine | An Offshore Wind Turbine Coating Machine is a specialized machine designed to cover the exterior of offshore wind turbines with protective coatings... |

Same products

| XD-MAX Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |