Wire Rope Pressing Machine

The wire rope pressing machine is a relatively common and best-selling wire rope rigging processing equipment in the world.

The steel wire rope press machine adopts the processing with no-cutting and plasticity method to let the aluminum sleeve fully fill in the mold cavity and tighten well of the steel wire rope without destroying wire sling parts strength. The cold working process of the pressing process reduces the damage to the wire rope.The rope slings made by the pressing machines have advantages including high binding strength, beautiful appearance, strong corrosion resistance,material saving and accuracy length. The strength of the pressed wire rope slings are fully in line with international standards. The main models of wire rope pressing machines we currently produced are capacity of 125, 350, 600, 1000, 1500, 3000, 5000 and so on..

How To Operate And Maintenance

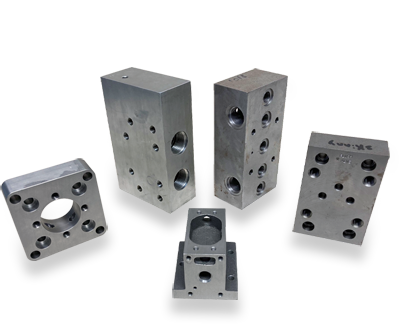

1. Different specifications wire ropes can be pressed by different molds.

All molds are made of high-quality steelt is processed under high temperature,cooling, tempering and other processes, thenfinished product with strong and durable properties come into being.

2.The hydraulic system is a dual-controlled, overflow valve regulating and magnetic pressure gauge obtained set which can

precisely control the pressure.Our 200-ton press can press ropes diameter from 6-22 mm.And warranties vary from 3 months to 2years for different fittings and main body.

3. Machine operation

* lnject the hydraulic oilfrom the air filter to the center line of the liquid level gauge before use.The filtration accuracy of theinjected hydraulic oil is less than or equal to 15um.

*Adjust the upper limit of the pressure gauge to 32Mpa, and the lower limit pointer to zero.

*After adjusting the pressure gauge,turn on the power, then observe whether the motor turns correctly. When the motor runs wellget the pump work for 5 minutes with no load. Then step on the left switch of the foot pedal, the pressure starts to increase andshould reach 32Mpa.lf the pressure is low, adjust the relief valve nut.Turn the nut clockwise to increase the system pressure, andcounterclockwise to decrease. When the system pressure reaches the rated working pressure of 32Mpa,operator should lock thenut. Observe whether the pump run normally, and check if each joint is leaking oil, also inspect the control switch is flexible andreliable or not. Solve problems in time when it comes out.

Please note:

*The overflow has been adjusted in the factory. the user shouldn't adjust it at will. f a large noise is found during the operation ofthe pumping station,i is caused by a large amount of air in the hydraulic system at the early stage of operation.ltis recommendedto make the piston run upper and lower several times to discharge the air, and the noise will be reduced.

*Select the corresponding consolidation tube, mold and pressure value per different pressing rope diameters.*Cover the steel wire rope with consolidation tube, and the end of the wire rope end must expose about Dia0.5-1.0.*Apply lubricating fluid to the cavity.

As one of lifting equipment manufacturers, we can offer sorts of lifting chainfor sale, if you have needs, please contact us.

Send product request

Other supplier products

| Master Links And Sub Assemblies | Master linksand Sub Assemblies are the main links to construct single leg or multiple leg lifting slings. Working as the control link, these links ... | |

| Pallet Stacker | Pallet Stackers are designed to lift and handle the palletised loads in factories and warehouses and distribution centers. With similar function... | |

| Snatch Block | Snatch Block is a lifting tool for transferring over short distances or to double/triple the capacity when used in conjunction with hoist/winches. ... | |

| Dumbwaiter Elevator China | Dumbwaiter elevator chinais a reliable, time-saving and practical way to transport items between different floors of a house or building. In terms ... | |

| Shackles | Shackles lifting equipmentis an essential parts to make connection between the lifting equipment such as hoist hook or lifting slings and the load ... |

Same products

| FOTON 12 TONS HOOKLIFT TRUCK | Seller: Hubei Yuantai Special Automobile Co., Ltd | The hooklift garbage truckis a special sanitation vehicle modified on the basis of Foton brand ch... | |

| China High Quality OEM CNC Machining steel metal parts | Seller: Ideal Vowin Industry Tech ltd | We are Ideal Group, specialized in custom machining with more than 15 years experience, with 150+... | |

| Light Blue Polyester Webbing | Seller: Zhejiang Tiantai Advans Textile Co., Ltd. | Model WB-004 Material Polyester Normal Width 20mm, 25mm, 32mm, 38mm and 50mm,100mm Packing 100m/r... | |

| Felt Logo Patch | Seller: Nanjing Jiamei Garment Accessory Factory | This is a patch with wool felt or Velcro base, silicone or rubber logo embossed. It is widely use... | |

| Reflective Labels | Seller: Nanjing Jiamei Garment Accessory Factory | always appear on safety uniforms but now it is fashion lucky devil by brands. It not only helps t... |