Milling Machine

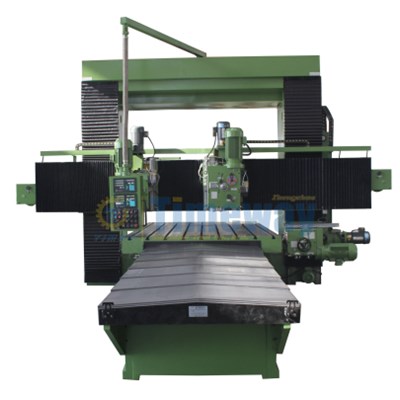

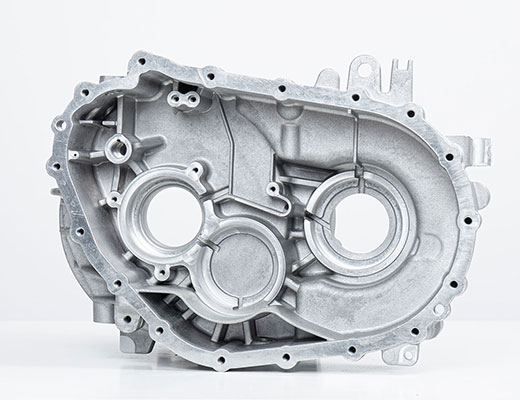

1.Gantry Type Milling MachineApplication:• M20 series heavy gantry milling machines are high-tech products with high working efficiency.The core technique of it originates from Taiwan, the scientific & logical design of the structure and the adoption of the advanced function unit can realize strong cutting function and safe & reliable movement and long working life.• It is used in machining work, moulding and some other industries,especially the machining of plane/ end face / inclined plane / T slot / combined guideway of large / medium/ small machine parts. Feature:• Heat-treatment technology & mechanical lubrication are adopted on the guideway of the machine body to reduce friction & prolong the working life.• Stepless table speed change.• Rigid machine bed / beam / column ensure stability of the machine in strong cutting.• Milling head can move vertically or swivel ±30°.SpecificationM2014/30M2014/40M2014/60M2016/30M2016 /40M2016/60M2020/40M2020/60 Table size (mm)1000×30001000× 40001000× 60001200× 30001200× 40001200 ×60001600× 40001600× 6000 Table feed speed (mm/min)0-260 Table rapid feed speed (mm/min)2500 Power of table motor (kw)5.57.55.57.5 Max.loading of table (kg Max.allowable workpiece size Length (mm Width (mm Height (mm Distance between columns (mm Spindle motor power (kw)7.5 Spindle taperISO50 Spindle speed (r.p.m)100-685 (6 Steps) Milling head swivel angle±30° Distance vertical spindle & table surface (mm Distance horizontal spindle & table surface (mm)100 Recommend diameter of tools (mm)Φ160 Overall dimensions Length (mm Width (mm Height (mm. Universal Swivel Head MillKey Feature:• Extra large work table and wide 3-axis travel ranges; • Stepless variable feed settings & rapid feed driven by Powerful servo motors on each axes;• Ball screw in all axis providing smooth and accurate operation;• Universal head can swivel to any position within 360°;• Dovetail guideway in X-axis, rectangular in Y & Z-axis.Standard Configuration:Universal swivel head, Electronic hand wheel, Central lubrication, Work lampCooling system, Draw bar, Operating tools, Operator manual in English.Options & Extra Cost:3-axis SINO D.R.O, 58pcs clamping kit, Machine vise, Dividing head, Rotary tableSpecification RUM460 RUM500 Table size (W×L) 460×1235mm 500×1600mm Table travel (X/Y/Z) 900×650×450mm 1200×700×500mm Table t-slots(No./Width/Pitch) 5-18-80mm 5-18-80mm Max. loading of worktable 800kg 1800kg Spindle taper ISO40 ISO50 Spindle speed range 30-2050r.p.m (27steps) 30-2050r.p.m (27steps) Swivel angle of milling head 360° 360° Table longitudinal & cross feed (X/Y) 10-1000mm/min 10-1000mm/min Table vertical feed (Z) 6-640mm/min 5-500mm/min Table rapid speed (X/Y/Z) 2200/2200/1100mm/min 2200/2200/1100mm/min Distance spindle - table surface 32-482mm 50-550mm Distance spindle - column 47-697mm 28-728mm Main motor power 5.5kw 7.5kw Feed motorAC servo motor X/Y:15NM; Z: 18NM Overall dimensions (L×W×H) 1835×2362×2090mm 2625×2460×2080mm Machine weight 4000kg 5000kg3. Bed-type MillStandard Accessories:• Milling chuck set; Spindle arbor; Sleeve; Drilling chuck; Draw bar; Quartz lamp; Coolant system;• Oil gun; Foundation bolts; Inner hexagon spanner; CE standard electric components; Operator• manua in English.Optional Accessories:3 axes DRO; Machine vice; Universal dividing head; Rotary table; Spindle guard(eye protection);58pcs clamping kits;SpecificationUnitBM713BM714BM715BM716Spindle taper ISO40ISO50ISO50ISO50Table sizemm1525x3201400x4002100x5002500x600Table travelmm1050x470800x4001500x6701500x650*700Table loadkgSpindle quill travelmm127105--NO./width/distance of T-slotmm3-14-80 Spindle speed steps 10variable speed1212Spindle speed ranger.p.m70~Distance between spindle axis and column guidewaymmDistance between spindle nose and table surfacemmSpindle motor powerHP57.57.511Overall dimension(LxWxH)mm2565x1920x22902290x2040x21203300x2380x27503200x3200x2720Net weightkg. Horizontal MillKey Features:• It is suitable to process flat, inclined surface, slots and gears on miscellaneous work pieces• With enough rigidity, it can bear heavy processing• Hardened and ground slide ways • Automatic feeds on X, Y, Z axes• Worktable can swivel ±45°Standard Configuration:End mill cutter, Cutter shaft, Arbor tension screw, Oil gun, Cooling system, Working light, General tools, Operator manual.Options & Extra Cost:Vertical milling head, 3-axis SINO D.R.O, 58pcs clamping kit, Machine vise, Dividing head, Rotary tableSpecificationUM320DUM360DUM400D Spindle taperISO40(V); ISO40(H)ISO40(V); ISO40(H)ISO50(H) ISO40(V) Distance spindle - table0-390mm30-510mm30-510mm Spindle speed range12 steps, 40-1300r.p.m12 steps, 60-1800r.p.m12 steps, 60-1800r.p.m Swivel angle of milling head±360°±360°±360° Table size (L×W)1250×320mm1500×360mm1700×400mm Max. rotations angle of table±45°±45°±45° Table travel (X/Y/Z)600/300/350mm900/390/500mm1100/390/500mm Table longitudinal & cross feed (X/Y)8 steps, 22-555mm/min8 steps, 22-410mm/min8 steps, 16-355mm/min Table vertical feed (Z)8 steps, 17-190mm/min8 steps, 15-220mm/min8 steps, 16-355mm/min X,Y-axis rapid feed speed1080mm/min1300, 1200mm/min1300, 940mm/min Z-axis rapid feed speed590mm/min600mm/min350mm/min Feed motor power0.75kw1.1kw1.1kw Max.loading of worktable300kg450kg500kg Table T-slots (No./Width/Pitch)3/14/70mm3/18/70mm3/18/70mm Z-axis guide way typeRectangularRectangularRectangular Y-axis guide way typeRectangularRectangularRectangular X-axis guide way typeDovetailRectangularRectangular Main motor power2.2kw4kw4kw N.W/G.W (one set)1650/1800kg2250/25002300/2450kg Model UMN320 UMN360 UMN420 Table size (W×L) 320×1600mm 360×1600mm 420×1800mm Table travel (X/Y/Z) - Manual 1020×300×410mm 1020×300×410mm 1280×360×470mm - Auto. 1000×280×400mm 1000×280×400mm 1250×350×450mm Table t-slots(No./Width/Pitch) 3-18-80mm 3-18-80mm 3-18-90mm Max.rotary angle of worktable ±45°- ±45° Max.loading of worktable 550kg 550kg 800kg Spindle taper 7:24, No.50 7:24, No.50 7:24, No.50 Spindle speed range 30-1500r.p.m (18steps) 30-1500r.p.m (18steps) 30-1500r.p.m (18steps) Arbor diameter Φ22,φ27,φ32mm Φ22,φ27,φ32mm φ32,φ50mm Table longitudinal & cross feed (X/Y) 15-750mm/min 15-750mm/min 22-1100mm/min Table vertical feed (Z) 5.7-280mm/min 5.7-280mm/min 8.3-410mm/min Table rapid speed (X/Y/Z) 2250/2250/844mm/min 2250/2250/844mm/min 2400/2400/900mm/min Spindle nose - worktable 30-440mm 50-460mm 30-500mm Horizontal spindle - arm 155mm 155mm 155mm Main motor power 7.5kw 7.5kw 11kw Feed motor 1.5kw 1.5kw 3kw Overall dimensions (L×W×H) 2327×2067×1720mm 2327×2067×1720mm 2522×2262×2047mm Packing size (L×W×H) 2220×2180×2280mm 2220×2180×2280mm 2460×2270×2280mm N.W/G.W 3300/3500kg 3200/3400kg 4640/5000kg5. Horizontal & Vertical Turret MillKey Features:• Hardened and ground table surface• Auto. feeds on X, Y axes, motorized rise and fall of table on Z axis• Spindle sleeve can tap, auto.feed with 3 steps, drill depth stop with display of measurement • Rectangular column guideway with high stability; Spindle with micro feed function • Headstock can swivel ±90° from left to right.• MD series with general step pulley mill head TM series with taiwan step pulley mill headStandard Configuration:Step pulley milling head, X/Y axes auto feed gear box, Z-axis lifting motor, ISO40 horizontal spindle, Coolant system, oil collecting plate, working lamp, elevating rotary handle, drill chuck, mill collets, draw bar, machine vise, wrench, spanner, middlesleeve,operation manual (English edition).ModelUnitMD600MD700MD800 Table size (W×L)mm320×1250320×1250320×1250(1370) Table travel (X/Y/Z) - Manual/automm600/300/280600/300//300/400 Table t-slots(No./Width/Pitch)mm Max. loading of worktablekg200200300 Spindle taper-ISO40(V), ISO40(H)ISO40(V), ISO40(H)ISO40(V), ISO40(H) Spindle speed range - Verticalr.p.m(8steps) 115-1750(8steps) 60-1500(8steps) 90-2000 - Horizontal(12steps) 40-1300(12steps) 40-1300(12steps) 40-1300 Spindle travelmm120120120 Max. drilling capacity auto. feedmm-1214 Spindle quill auto. feedmm-(3steps) 0.15,0.08,0.25(3steps) 0.15,0.08,0.25 Micro feed function---Yes Vertical spindle to tablemm Vertical spindle to columnmm Horizontal spindle to tablemm Head Swivel (L & R)±90° X,Y axes feed speedmm/min22-555 X,Y,Z axes rapid feed speedmm/min1080/1080/590 Main motor powerkw1.5(V), 2.2(H)1.5(V), 2.2(H)2.2(V), 2.2(H) Feed motorkw0.75 Overall dimensionmm1780×1500×21001780×1500×21001700×1500×2270 N.W/G.Wkg1450/15501450/15501550/1650ModelUnitTM500TM700TM800 Table size (W×L)mm320×1250320×1250360×1250 Table travel (X/Y/Z) - Manual/automm600/300/280800/300/4001000/320/400 Table t-slots(No./Width/Pitch)mm Max. loading of worktablekg300300400 Spindle taper-ISO40(V), ISO40(H)ISO40(V), ISO40(H)ISO40(V), ISO50(H) Spindle speed range - Verticalr.p.m(16steps) 80-5440(16steps) 70-7200(16steps) 70-7200 - Horizontal(12steps) 40-1300(12steps) 40-1300(12steps) 60-1800 Spindle travelmm127145145 Spindle quill auto. feedmm(3steps) 0.15,0.08,0.25(3steps) 0.4,0.08,0.15(3steps) 0.4,0.08,0.15 Vertical spindle to tablemm Vertical spindle to columnmm Horizontal spindle to tablemm Max. drilling capacity of auto-feedingmm10 Head Swivel (L & R)°±90° Head Tilting ( F & B)°±45°FixFix X,Y axes feed speedmm/min22-555 X,Y,Z axes rapid feed speedmm/min1080/1080/590 Main motor powerkw2.2(V), 2.2(H)3.75(V), 2.2(H)5.5(V), 4(H) Feed motorkw0.75 Overall dimensionmm1700×1500×21501780×1500×22702220×1790×2360 N.W/G.Wkg1450/16001650/17502450/26506. Bridgeport Type Turret MillKey Features:• Hardened and ground table surface;• Universal mill head can be tilted and swiveled;• Auto. spindle feeds with 3 steps on X, Y, Z axes;• Spindle features micrometer depth stop;• Work table features large clamping area;• Powerful coolant device included in machine base. Milling Head:All models are equipped with step pulley mill head from TUING YUOH INDUSTRY, TAIWAN as standard; Variable speed stepless mill head or Inverter mill head as optional & Extra costs.Lead Screw:All machines adopt lead screw from SHYH MIN MACHINERY, TAIWAN. SpecificationUnitM230M250M300M330Table Size (W × L)mm230×1067254×1270305×1370330×1370230×1246254×1370305×1500330×1500Longitudinal Travel (X)mm650/840850/950870/1000840/1000Cross Travel (Y)mmVertical Travel (Z)mmT-slot No. x Sizemm3 × 16Over Ram Travelmm315470500Spindle To TablemmSpindle Taper - R8 (Optional : ISO30/ISO40)ISO40Spindle Travelmm127Spindle Speedr.p.m50HZ: 66-4540; 60HZ: 80-5440 (16 Steps)Auto. Quill Feedmm/rThree steps: 0.04 (0.0015″) / 0.08 (0.003″) / 0.15(0.006″)Spindle Motorkw2.25kw/3HP3.75kw/5HPHead Swivel (L & R) °90°Head Tilting ( F & B) °45°X.Y.Z Guide Way-▲▲▲▲■■▲■■▲■■Dimension of packageOnemm1400×1476×20301516×1550×20801566×1650×20801800×2016×2180Twomm1450×1570×20801650×1790×21701720×1800×21751800×2200×2180Threemm1450×2180×20801650×2285×2235--Gross Weightkg. Universal Tool MillKey Features:• Automatic feeds on X, Y, Z axes• Outer arbor support for horizontal milling• Heavily ribbed cast-iron machine stand ensures maximum static and dynamic rigidity• Optimum layout of operating controls on the right-hand side• Vertical head quill for drilling, with hand lever feed• Quill stroke 80 mm• Central lubrication• Chip collector panStandard Configuration:4 cutter arbors Ø (16, 22, 27, 32 mm), reducing sleeves MT1, MT2, MT3, collet chuck with collets Ø(2,3,4,5,6,8,10,12mm), draw bar, coolant system, chip tray, outer arbor support for horizontal milling, work lamp, operator manual. Options & Extra Cost:3-axis SINO position indicatorRotary table, Angular table 320×620mmUniversal boring headMachine viseDividing headSpecificationUTM300AUTM400A Horizontal table Horizontal table (L×W)750×300mm800×400mm T-slots (No./width/space)5/14/60mm6/14/63mm Vertical table Vertical table (L×W)830×225 mm1060×250 mm T-slots (No./width/space)3×14×63 mm3×14×63 mm Distance table - guideway188mm165mm Table longitudinal travel (X-axis)405mm(manual); 395mm(auto)600mm Table vertical travel (Z-axis)390mm(manual); 380mm(auto)400mm Max. Table load capacity160kg200kg Horizontal spindle Spindle taperISO40ISO40 Spindle - horizontal table surface105 - 485 mm105 - 485 mm Vertical spindle Spindle taperISO40ISO40 Speed range 40~2000rpm40~2000rpm Quill stroke80mm80mm Swivel angle of mill head Spindle -horizontal table surface135~515mm135~535mm Distance spindle - guideway682mm832mm Feed speed X/Y/Z-axis10 - 380 mm/min10 - 380 mm/min Rapid feed X/Y/Z-axis1200 mm/min1200 mm/min Main motor power2.2kw3kw Feed motor feed0.75kw1.1kw Overall dimensions (L×W×H)1215×1200×1800mm1390×1430×1820mm Machine weight1000kg1400kg8. CNC Milling Machine Key Features: • Hardened and ground slide ways with long service life • X/Y/Z axis feeds are effected by ball leadscrews• The spindle system is high in rigidity and accuracy• It is idea equipment for small maintain workshop Standard Configuration:• CNC controller: Siemens SINUMERIK 808D• Servo main motor • High speed spindle unit• Pneumatic tool clamping way• Automatic lubrication system• Coolant system, Working light • Operator manual in English SpecificationKBM7124KBM7125KBM7136C Table size (W×L)240×800mm250×1000mm360×1250mm Table travel (X/Y/Z)430/280/400mm535/320/375mm900/350/500mm No./width/distance of T-slot3/16/60mm3/16/60mm3/18/80mm Max.loading weight on worktable60kg120kg300kg Distance from spindle nose to table50-450mm25~400mm100~600mm Distance from spindle to column297mm345mm460mm Spindle taperBT30BT30BT40 Spindle speed range6000r.p.m6000r.p.m6000r.p.m Tool clamping wayPneumaticPneumaticPneumatic Tool magazine capacity4pcs simple ATC-- Rapid feed speed ( X,Y,Z)6m/min6m/min6m/min Main motor power2.2/3.7kw2.2/3.7kw5.5kw Positioning accuracy0.04mm0.04mm0.04mm Repeatability accuracy0.02mm0.02mm0.02mm Machine weight1000kg1600kg2200kg Overall dimension (L×W×H)1640×1205×1950mm1516×1764×1708mm2220×1850×2350mm9. Vertical Mchining CenterFeature:• CNC controller: FANUC 0i mate-MD or SIEMENS 808D• High speed spindle unit;• 3-axis linear guide-ways• Electronic hand wheel (MPG);• Oil and water separated design;• Interval auto-lubricating;• Full splash guard;• Tricolor alarm light;• Operation manuals.SpecificationUnitVMC500VMC745LVMC850L Table X-axis travelmm500 (linear way)600 (linear way)800 (linear way) Table Y-axis travelmm320 (linear way)450 (linear way)500 (linear way) Table Z-axis travelmm400 (linear way)500 (linear way)580 (box way) Table size ( L×W)mm800×320800×4501050×500 No./width/distance of T-slotmm Max.loading of tablekg300500600 Spindle to table surfacemm120~520130~630110~660 Spindle to vertical guidewaymm360485560 Rapid feed speed ( X,Y,Z)m/min18(X,Y); 18(Z)24(X,Y); 24(Z)20(X,Y); 18(Z) Feed speed ( X,Y,Z)mm/min Spindle taper -BT30BT40BT40 Spindle speed ranger.p.m Spindle motor powerkw3.7/5.55.5/7.57.5/11 Tool magazine capacityqty10 (drum type)16 (drum type)16 (drum type) Max. diameter of toolmm608080 Max.length of toolmm200300300 N.W.kg Overall dimensionmm1600×1840×21102100×2450×23003500×2550×240010. 5-axis VMCAdvantages of machine:• Improved gantry framework and the whole machine structure design.• Adopt artificial lidan bed body.• Direct-drive technology guarantees better dynamic response ability. • Driven at the center of gravity.• Linear axis rapid feeding speed is 60m/min.• High dynamic response technical.• Higher precision, higher processing efficiency.• Pick-up type tool magazine, tool change time is short.• High-speed C-axis realize milling and turning compound function.• A-axis swiveling angle range: -130deg to +130deg.• Intelligent power supply, energy saving 20% during service life.Advantages of CNC System: • Perfect five-axis technology (RTCP, inclined plane machining)• High-speed information interaction.• High resolution, high precise frequency control scheduling.• Precision perception for position or angle.• Multi-channel control technology.• Systems support wireless probe, tool setting gauge access.• Error compensation function: the bidirectional pitch compensation, linearity compensation(including each deflection compensation) and vertical degree of compensation etc.• Secondary development and offline 3D simulation system.SpecificationUnitFMC-400FMC-600FMC-800FMC-1250CapacityMax. swiveling diameter of workpiecemmΦ450Φ800Φ1100Φ1400Max. milling widthmmMax. milling heightmmThe diameter of worktablemmΦ450; 370*370Φ650*540Φ800; Φ625Φ1250*1000Max. weight of workpiecekgTravelX/Y/Z-axis travelmm400/380/350800/650/450900/800/54011250/1450/1000A-axis swiveling angle range°-130°- +130°-130°- +130°-130°- +130°-130°- +130°C-axis rotary angle range°Any-angleAny-angleAny-angleAny-angleSpindleMax. spindle torqueN.m28/40; 5.6/1042/6284/125; 115.5/183200/300Max. spindle speedrpm16000; ; 1000012000Spindle motor rated powerkw16; 7.515.530; 2456.5Type of tool shank HSK-A50; HSK-A63 BT30HSK-A63HSK-A63HSK-A100Tool center out of the water OptionalOptionalOptionalOptionalSpindle directional YesYesYesYesPositioning lock NoNoNoNoA-axisType of drive Direct-drive by torque motorDirect-drive by torque motorDirect-drive by torque motorDirect-drive by torque motorTorque of drive S1/S6N.m689/1250(single-drive)1880/34802700(single-drive)7200/13200C-axisType of drive Direct-drive by torque motorDirect-drive by torque motorDirect-drive by torque motorDirect-drive by torque motorTorque of drive S1/S6N.m315/582860/16201240/23004400/7478Max. feed speedX/Y/Z-axism/min40; 4848; 6048; 6048; 60A-axisrpm30303015C-axisrpm80807540Min setting unitX/Y/Z-axisum1; 0.11; 0.11; 0.11; 0.1C-axis°0.001°; 0.0001°0.001°; 0.0001°0.001°; 0.0001°0.001°; 0.0001°Full closed-loop controlX/Y/Z-axis StandardStandardStandardStandardA/C-axis StandardStandardStandardStandardPositioning accuracyX/Y/Z-axisum8; 58; 58; 58; 5A/C-axis"8; 58; 58; 58; 5Repositioning accuracyX/Y/Z-axisum5; 35; 35; 35; 3A/C-axis"5; 35; 35; 35; 3Tool magazineCapacity 22323650Max. diameter of toolmmΦ63Φ80Φ125Φ125Max. length of toolmmMax. weight of toolkg781030AccessoryWireless workpiece gauge headum±3(Repositioning accuracy)±3(Repositioning accuracy)±3(Repositioning accuracy)±3(Repositioning accuracy)Tool setting gaugeum±3(Repositioning accuracy)±3(Repositioning accuracy)±3(Repositioning accuracy)±3(Repositioning accuracy)Machine weightN.WkgCNC systemModel GNC61 CNC systemGNC61 CNC systemGNC61 CNC systemGNC61 CNC system

Other supplier products

|

|

Deep Hole Drilling & Boring Machine |

1.CNC Deep Hole Boring and Drilling Machine -- DBK-100Application:●CNC deep hole drilling and boring machine is mainly for the processing of cylind... |

|

|

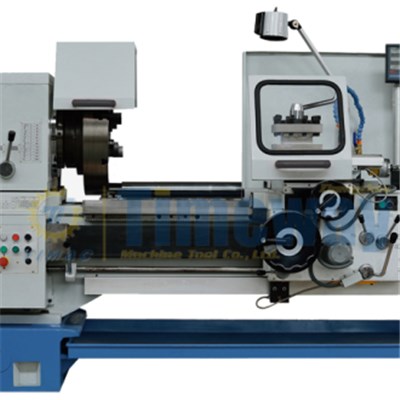

Oil Country Lathe |

1. Manual Oil Country Lathe Q-225Features:● The oil country lathes are used for turning pipe threads,Website:, inside and outside.● They can be use... |

|

|

Grinding Machine |

1. Gantry Type Surface GrinderFeatures:• SIEMENS touch operation panel • Z-axis: Rectangular guideway; Y-axis: precision linear guideway (HIWIN, T... |

|

|

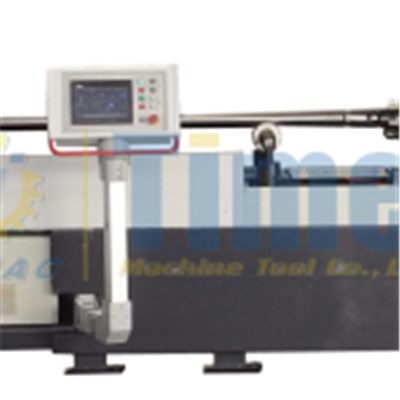

Deep Hole Honing Machine |

1.Deep Hole Honing Machine -- DHK-100 DHK-200Features:●This series NC deep hole honing machine is the dedicated machine for honing and polishing of... |

|

|

Drill Tools |

Drill Tools,Website: Field Euipment |

All supplier products

Same products