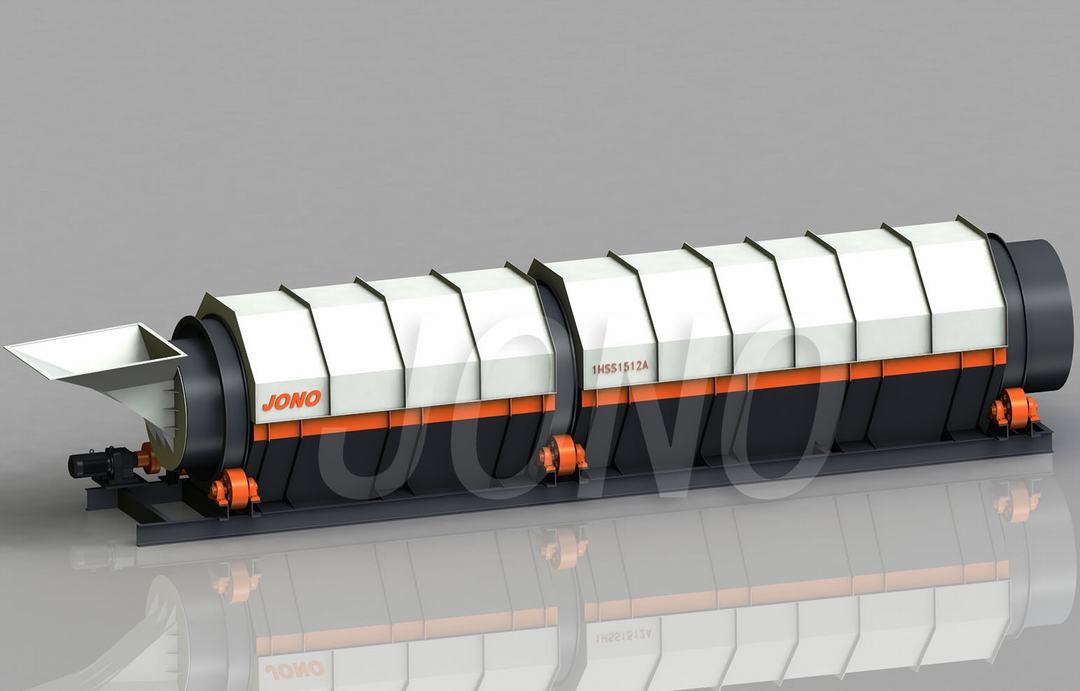

Quadruple-Shaft (Shear) Shredder

The cutter chamber of 1PSS quadruple-shaft (shear) shredders are composed of double auxiliary shafts at the upper layer and double main shafts at the lower layer. Auxiliary cutter rings at the upper layer are functioning in forcible feeding, which could increase the output of the main cutter rings. Meanwhile, materials of big sizes are brought back to shredding chamber to be shredded repeatedly, so as to achieve the purpose of controlling the size of materials to be discharged. Main cutter rings at the lower layer have special shape which combines the technology of chopping and shearing, so that it achieves the purpose of shattering and volume reduction by shearing, crushing, tearing, puncturing, and hacking, etc. The quadruple-shaft (shear) shredder is the key equipment to achieve highly efficient and uniform shredding of various kinds of solid waste.

Scope of Application

Waste, paper boxes, paper rolls and wood derived from papermaking factories;

Plastic buckets, plastic shells of electrical appliances;

Metal cans, thin-wall metal drums, metal shells of electrical appliances;

Waste printed circuit boards, mixed light industrial waste;

Carpets, woven bags and riddled remains of municipal solid waste,

Light construction waste, medical waste;

Biomass and alternative material manufacturing industries;

Especially suitable for applications having higher requirement on particle size, e.g., uniformly small or medium sized slices after shredding

Features

Low speed, high torque, low noise;

High throughout, controllable output material sizes, uniform output, high efficiency;

No need for extra pressing device, with forcible feeding provided by auxiliary cutter rings;

Patented screen maintenance construction, convenient maintenance;

Entirely modular construction, easy to maintain and change the parts;

Alloy steel and heat treated cutter rings, long lifetime and fine wear-resistance;

Simply exchange of the cutters to the worn group cutter rings (optional);

Direct connection between motors and shredding shafts, achieving high efficiency and low failure rate;

More stable running with superpower shredding shafts driven by hydraulic motor;

Unshreddable material ejection door and maintenance displacement system (optional);

Better protection of bearings with multiple sealing system;

Ribbed shafts, ensured locked state between the cutter rings and ribs while operation;

Equipped with multi-protection system against eventual overloads for safe operation;

The intelligent inverter drive technique enables real-time monitoring over the torque force of cutter rings and shafts, and automatic increase or reduction of the rotating speed as required, achieving optimal processing result.

Equipment Specifications

|

Model |

Main cutter ring rotational diameter |

Cutter chamber length |

Cutter chamber width |

Main shaft rotational speed |

Cutter ring thickness |

Screen hole diameter |

Installed power |

|

(mm) |

(mm) |

(mm) |

(rpm) |

(mm) |

(mm) |

(Kw) |

|

|

1PSS2502 |

Φ245 |

314 |

820 |

16-25 |

20 |

3+3 |

|

|

1PSS2504 |

Φ245 |

466 |

820 |

25 |

20 |

2x(7.5~11) |

|

|

1PSS2506 |

Φ245 |

618 |

820 |

25 |

20 |

||

|

1PSS2508 |

Φ245 |

846 |

820 |

25 |

20 |

||

|

1PSS3410 |

Φ340 |

1020 |

800 |

15-25 |

37 |

40 |

2x(15~22) |

|

1PSS3412 |

Φ340 |

1220 |

800 |

15-25 |

37 |

40 |

|

|

1PSS3414 |

Φ340 |

1420 |

800 |

15-25 |

37 |

40 |

|

|

1PSS4612 |

Φ460 |

1200 |

1300 |

10-15 |

50 |

60 |

2×15+2×(22~30) |

|

1PSS4614 |

Φ460 |

1400 |

1300 |

10-15 |

50 |

60 |

|

|

1PSS5314 |

Φ530 |

1400 |

1560 |

10-15 |

50 |

60 |

2×30+2×(45~75) |

|

1PSS5316 |

Φ530 |

1600 |

1560 |

10-15 |

50 |

60 |

|

|

1PSS5318 |

Φ530 |

1800 |

1560 |

10-15 |

50 |

60 |

Send product request

Other supplier products

| Eddy Current Non-Ferrous Metal Separator | The eddy current separator is composed of conveyor belt, magnetic poles and eddy current drum. The drive motor of the conveyor belt is at the side ... | |

| Universal Tilting Rotary Furnace | 1HQW universal tilting rotary furnace,a great leap in melting technology. 1HQW universal tilting rotary furnace is used to melt aluminum scraps, l... | |

| trommel screen | JONO’s trommel screens have solid construction, and enjoy long life time. The driving wheels are of friction-resistant rubber and yield very ... | |

| Quadruple-Shaft (Shear) Shredder | The cutter chamber of 1PSS quadruple-shaft (shear) shredders are composed of double auxiliary shafts at the upper layer and double main shafts at t... |

Same products

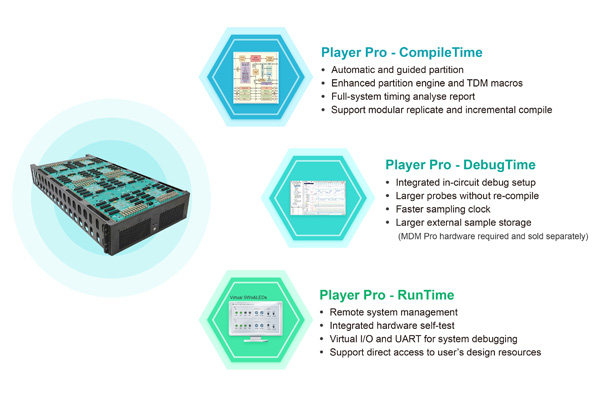

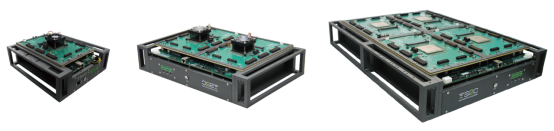

| S2C Prototyping Software Prodigy Player Pro | Seller: S2C Limited | Prodigy Player Pro Prodigy Player Pro is a rapid prototyping softwarethat works with the FPGA-ba... | |

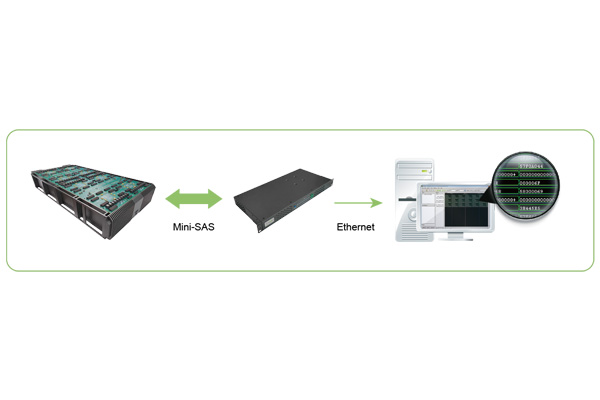

| S2C Prodigy Multi-Debug Module Pro | Seller: S2C Limited | Multi-Debug Module Pro The S2C Prodigy Multi-Debug Module is an innovative debug solution for FP... | |

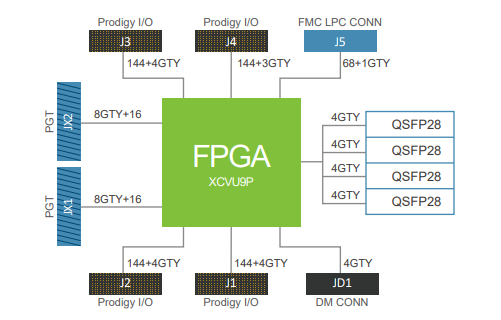

| Prodigy S7-9P Logic System – Prototyping with VU9P FPGA | Seller: S2C Limited | Prodigy S7-9P Logic System – Prototyping with VU9P FPGA Prodigy S7-9P Logic System The Prod... | |

| Virtex UltraScale (VU) Prodigy Logic Systems | Seller: S2C Limited | Virtex UltraScale Series S2C's Prodigy Virtex UltraScale VU440 Logic Systems are engineered to le... | |

| Prodigy S7-19P Logic System – Prototyping with VU19P FPGA | Seller: S2C Limited | Prodigy S7-19P Logic System The Prodigy S7-19P Logic Systems utilize Xilinx's highest capacity FP... |