Peek Tubing Material

Peek Tubing Material

PEEK has great machinability, excellent dimensional stability, high-temperature resistance, creep resistance and hydrolysis resistance, can be used in a variety of machining ways, easy to control the tolerance.

Applications: Sheets/ Rods/ Tubes/ 3D Filaments

Characteristics and Properties of Peek Tube Material

Polyether ether ketone is a high-performance PEEK thermoplastic polymer that is highly resistant to chemicals, temperature, and abrasion, making it a popular choice for applications requiring high strength and durability. Some of the key characteristics and properties of PEEK tube material include:

Temperature Resistance: PEEK can withstand high temperatures up to 260°C (500°F), making it an excellent choice for applications in extreme environments.

Chemical Resistance: PEEK is highly resistant to many chemicals, including acidic and alkaline substances, solvents, and hydrocarbons.

Mechanical Properties: PEEK has excellent mechanical strength, fatigue resistance, and dimensional stability, making it ideal for applications requiring high strength and stiffness.

Electrical Properties: PEEK has high dielectric strength and is an excellent electrical insulator.

Hydrolysis Resistance: PEEK is highly resistant to moisture and hydrolysis, making it an ideal choice for applications in wet and humid environments.

Biocompatibility: PEEK is biocompatible and is often used in medical and pharmaceutical applications.

In summary, PEEK tube material offers exceptional temperature resistance, chemical resistance, mechanical properties, electrical properties, hydrolysis resistance, and biocompatibility, making it a versatile material suitable for a wide range of PEEK polymer applications.

Advantages and Disadvantages of Using Peek Tube Material

PEEK plastic tubingoffers several advantages and disadvantages, which must be considered when choosing it for applications.

Advantages:

High Strength and Durability: PEEK is a highly durable material that offers excellent mechanical strength and dimensional stability.

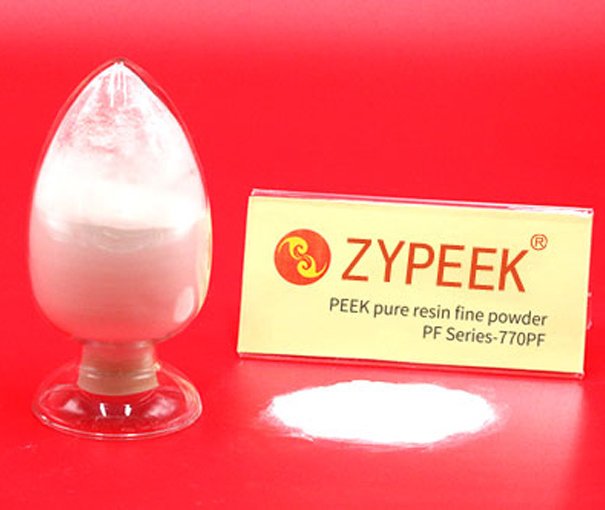

Chemical Resistance: PEEK rawmaterialis highly resistant to a wide range of chemicals, including acids and solvents, making it ideal for applications in harsh chemical environments.

Temperature Resistance: PEEK has a high melting point and is resistant to high temperatures up to 260°C (500°F).

Biocompatibility: PEEK material is biocompatible, which makes it an ideal choice for use in medical and pharmaceutical applications.

Excellent Electrical and Dielectric Properties: PEEK is an excellent electrical insulator and offers high dielectric strength.

Disadvantages:

Cost: PEEK material is expensive compared to other thermoplastics, which may make it less desirable for some applications.

Machining: PEEK is a difficult material to machine and may require specialized equipment and expertise.

Hydrolysis Sensitivity: PEEK may be sensitive to hydrolysis, which can cause degradation of the material over time.

Flammability: PEEK is flammable and may require special consideration for applications in high-risk environments.

In summary, tube PEEK offers several advantages, including high strength, chemical resistance, temperature resistance, biocompatibility, and excellent electrical properties. However, it can be expensive, difficult to machine, sensitive to hydrolysis, and flammable.

As a peek material supplier, we will do our best to meet all the needs of customers.

Send product request

Other supplier products

| Peek in Bearing Material | Peek in Bearing Material Due to its excellent mechanical strength, dynamic fatigue resistance, high-temperature resistance, creep resistance, se... | |

| Peek in Bearing Material | Peek Bearing Material Due to its excellent mechanical strength, dynamic fatigue resistance, high-temperature resistance, creep resistance, self-... | |

| Color PEEK R&D Series | PEEK ColorR&D Series can be customized according to the customer's own demand. Different PEEK plastic colorscan be chosen for our PEEK raw mate... | |

| CA Series-550CA30 PEEK Carbon Fiber Reinforcement | CA Series-550CA30 PEEK carbon fiberreinforcement is a 30% carbon fiber reinforced PEEK plastic material, the addition of carbon fiber significantly... | |

| PEEK in Electronic & Electrical | PEEK is a C-level insulating material, keeps excellent insulating properties under high temperature, high pressure, high humidity and other environ... |

Same products

| Keyboard Mould | Seller: Green Vitality Industry Co., Limited | Mainly electronic molds we make are electronic housing mold, electronic components mold, electron... | |

| Industrial Plastic Injection Mold | Seller: Green Vitality Industry Co., Limited | Plastic Mould Industry The industrial plastic injection moldis replacing metal products in many ... | |

| Home Appliance Mould | Seller: Green Vitality Industry Co., Limited | GV Mold has rich experience in home appliance molds (such as television, refrigerators, fans, was... | |

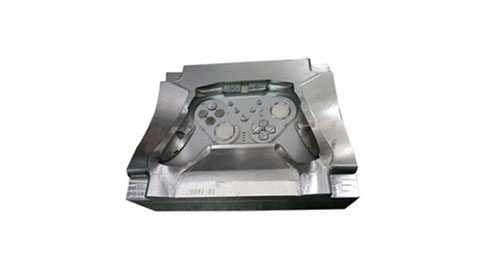

| Game Controller Mold | Seller: Green Vitality Industry Co., Limited | To increase the production efficiency, we need optimize the mold cooling system to shorten the cy... | |

| Filter and Flow Limiting Apparatus | Seller: Green Vitality Industry Co., Limited | The family mold is used to produce injection parts for liquid filtration and flow monitoring an... |