Peek Tubing Material

Peek Tubing Material

PEEK has great machinability, excellent dimensional stability, high-temperature resistance, creep resistance and hydrolysis resistance, can be used in a variety of machining ways, easy to control the tolerance.

Applications: Sheets/ Rods/ Tubes/ 3D Filaments

Characteristics and Properties of Peek Tube Material

Polyether ether ketone is a high-performance PEEK thermoplastic polymer that is highly resistant to chemicals, temperature, and abrasion, making it a popular choice for applications requiring high strength and durability. Some of the key characteristics and properties of PEEK tube material include:

Temperature Resistance: PEEK can withstand high temperatures up to 260°C (500°F), making it an excellent choice for applications in extreme environments.

Chemical Resistance: PEEK is highly resistant to many chemicals, including acidic and alkaline substances, solvents, and hydrocarbons.

Mechanical Properties: PEEK has excellent mechanical strength, fatigue resistance, and dimensional stability, making it ideal for applications requiring high strength and stiffness.

Electrical Properties: PEEK has high dielectric strength and is an excellent electrical insulator.

Hydrolysis Resistance: PEEK is highly resistant to moisture and hydrolysis, making it an ideal choice for applications in wet and humid environments.

Biocompatibility: PEEK is biocompatible and is often used in medical and pharmaceutical applications.

In summary, PEEK tube material offers exceptional temperature resistance, chemical resistance, mechanical properties, electrical properties, hydrolysis resistance, and biocompatibility, making it a versatile material suitable for a wide range of PEEK polymer applications.

Advantages and Disadvantages of Using Peek Tube Material

PEEK plastic tubingoffers several advantages and disadvantages, which must be considered when choosing it for applications.

Advantages:

High Strength and Durability: PEEK is a highly durable material that offers excellent mechanical strength and dimensional stability.

Chemical Resistance: PEEK rawmaterialis highly resistant to a wide range of chemicals, including acids and solvents, making it ideal for applications in harsh chemical environments.

Temperature Resistance: PEEK has a high melting point and is resistant to high temperatures up to 260°C (500°F).

Biocompatibility: PEEK material is biocompatible, which makes it an ideal choice for use in medical and pharmaceutical applications.

Excellent Electrical and Dielectric Properties: PEEK is an excellent electrical insulator and offers high dielectric strength.

Disadvantages:

Cost: PEEK material is expensive compared to other thermoplastics, which may make it less desirable for some applications.

Machining: PEEK is a difficult material to machine and may require specialized equipment and expertise.

Hydrolysis Sensitivity: PEEK may be sensitive to hydrolysis, which can cause degradation of the material over time.

Flammability: PEEK is flammable and may require special consideration for applications in high-risk environments.

In summary, tube PEEK offers several advantages, including high strength, chemical resistance, temperature resistance, biocompatibility, and excellent electrical properties. However, it can be expensive, difficult to machine, sensitive to hydrolysis, and flammable.

As a peek material supplier, we will do our best to meet all the needs of customers.

在线联系供应商

Other supplier products

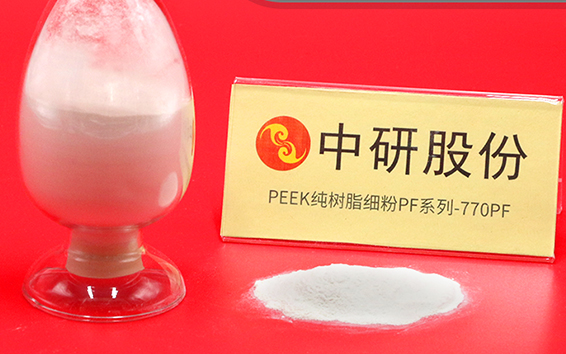

| Grade PF PEEK Pure Resin Fine Powder | The material is obtained by grinding the coarse powder (D50 is 13 micron ~ 75 microns) . It can be used as moulding material, spraying material and... | |

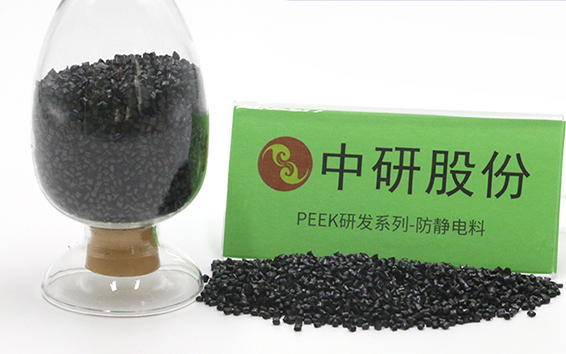

| Antistatic Material PEEK R&D Series | AntistaticPEEKR & D Series has excellent electrical insulation, high temperature resistance and wear resistance. Anti-static peek color is blac... | |

| PEEK Valve in Home Appliances | PEEK has good wear resistance, self-lubrication, non-toxicity, high-temperature resistance, low density, and can decrease noise, reduce energy cons... | |

| CA Series-770CA30 PEEK Carbon Fiber Reinforcement | CA Series-770CA30 carbon fiber filled peekreinforcement is widely used in automobile and aviation fields. It is widely used in automobile fuel pump... | |

| PEEK Seal Material in Mechanical | PEEK Seal Materialin Mechanical PEEK is a kind of mateiral with both rigidity and toughness, excellent mechanical properties, wear resistance, s... |

Same products

| Two-Shot Injection Molds | 卖方: WIT MOLD LIMITED | Two-Shot Injection Molds Advantages of two-shot injection molding The benefits of Double Inject... | |

| precision injection molding | 卖方: WIT MOLD LIMITED | precision injection molding Precision injection moldingis a method demanding unparalleled accura... | |

| Custom Plastic Molds molding | 卖方: WIT MOLD LIMITED | Custom Plastic Molds molding Plastic Molds molding servicesprovide many extremely versatile part... | |

| Negative Pressure Physiotherapy Tank Molds | 卖方: Zhuozhou Yihua Mould Factory | The negative pressure tank is a disposable consumable for male negative pressure treatment. This ... | |

| PLC Casing Molds | 卖方: Zhuozhou Yihua Mould Factory | The PLC housingbelongs to a kind of rail electrical module. It not only needs to achieve the fit ... |