Pad printing silicone rubber liquid raw material elastic material electronic

Pad printing silicone rubber liquid raw material elastic material electronic

Description

Two-component silicone, tin-curing, flowable, vulcanizes at room temperature.Can be used for a long time in the temperature range of - 65 ° C - 200 ° C and keep its soft and elastic properties.

Application

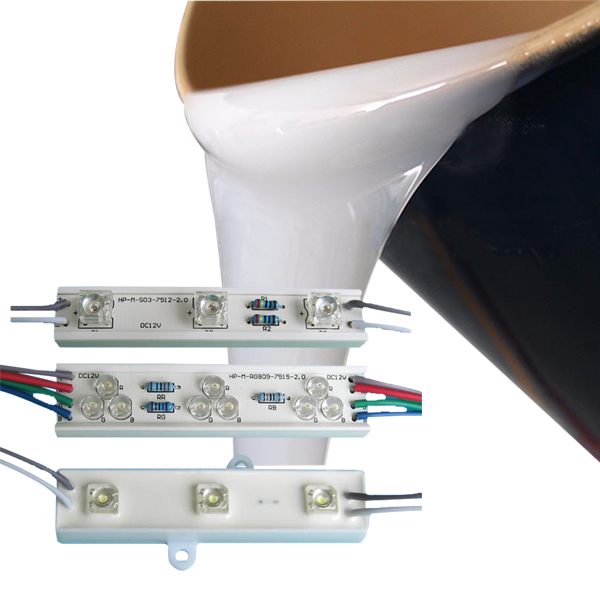

Suitable for making printing pads, tampo pads for transfer patterns and contents to the porcelain /ceramics, plastic, electroplated products, toys, tableware and so on.

Features& Advantages

²The liquid silicone very delicate without any impurities or particles.

²Excellent resilience & elasticity

²Durable, the printing times can more than 50000 times without sign of tearing or wearing on pads for some items.

²Good oil absorption effect

²The pattern is printed with great clarity and completeness.

²Keep good quality even though 200%-300% silicone oil added

²Low shrinkage

²No bubbles

²Adjustable with excellent antistatic performance

Typical propertiesINI-916

|

PropertiesIndex |

Test Report |

|

|

Before Curing |

Appearance |

Fluid |

|

Viscosity(cps) |

45000±5000 (Adjustable) |

|

|

Operating |

Mixing Ratio (By weight) |

100:3 |

|

Operating Time(25℃/min) |

30~40 (Adjustable) |

|

|

Curing time(hr,basically cured) |

3~5 (Adjustable) |

|

|

Curing time(hr, perfectly cured) |

12 |

|

|

After Curing |

Hardness (shore A) |

14±3 |

|

Tear strength (kN/m) |

28±3 |

|

|

Tensile strength (Mpa) |

4.8±0.4 |

|

|

Shrinkage (%) |

≤0.3 |

|

|

Elongation (%) |

510~400 |

|

|

Density (g/cm) |

1.09 |

|

Operation instructions

1.Mix part A and pars B evenly with 100:3 mixing ratio.

Notes: 1) Weigh the two parts exactly by electronic weight. For example, the operation time will be shorten after adding too much catalyst.

2)Mix part A and part B evenly. Otherwise the silicon rubber will be partly solidified which will make the finished molds meet a short life and waste silicon rubber.

2.Vacuum pumping

Notes: 1) This step is not have to have, but it is best if there is one. It will discharge all air in the mixture successfully, so as to ensure that therewill be no bubbles in the finished silicone pad.

2) This step is less than 10 minutes. Otherwise, itWill cause cross-linking reaction, and no morefurther steps will be available.

3. Pouring

We suggest to set the silicone pad for another 12 hours after demould before printing.

Package

5KG, 20KG, 25KG and 200KG per drum.

(There are metal drum and plastic drum for your choice for 5KG and 20KG)

Shelf life

Twelve(12) months when stored under dry and cool place by original package under 25℃.

WhyChooseus

1.Powerfulfactorywithaproductioncapacityof8000perday, we are the more than 10 years factory in China, with excellent and stable quality.

2.High-endresearchanddevelopment(freesample)

BeingaleadingliquidsiliconemanufacturerinChina,wehaveaprofessionalR&DteamandQCteam(12experts)andourproductisRoHS,MSDS,ISO,REACH,ULapproved,sothereisnoneedtoworryaboutthequality.

3,Efficientservice

Wecanprovidefreetrainingofsiliconetechniqueandfreesiliconesamples.wehaveaprofessionalsalesteamwhowillsolveyourproblemspatiently.Besides,withefficientlogisticsdistributionsystem,youcouldgetyougoodsearlier.Last,goodaftersalesservice,webuildlongtermcooperationrelationship,oncethereisqualityproblem,wecouldsolverightaway.Moreimportantly,returnandexchangeareacceptedwhilequalityproblemsoccurred.

We can provide the free sample, more details about silicone rubber, pls contact Ms Lisa at:

Mobile/ Whatsapp/: +86 188 1670 2967

2967or A108059

E-mail:lisasilicone(at)

Twitter/Facebook:lisasilicone

Send product request

Other supplier products

| two parts tin cure silicone rubber for mold free sample | 1. Description Two-component silicone, tin-curing, flowable, vulcanizes at room temperature. Can be used for a long time in the temperature range... | |

| life casting food grade silicone rubber soft sex doll two parts liquid silicone | life casting food grade silicone rubber soft sex doll two parts liquid silicone platinum cure silicone rubber prosthesis hands foot ear product li... | |

| sealing material electrical insulation silicon glue sealant corrosion-proof | sealing material electrical insulation silicon glue sealant corrosion-proof Description Two-component silicone,platinum-curing/ addition-cure ty... | |

| Pad printing silicone rubber liquid raw material elastic material electronic | Pad printing silicone rubber liquid raw material elastic material electronic Description Two-component silicone, tin-curing, flowable, vulcanizes... | |

| softest platinum silicone rubber hepa air filter high quality clear silicon gel | softest platinum silicone rubber hepa air filter high quality clear silicone gel Description Two-component silicone,platinum-curing/ addition-cu... |

Same products

| Easy-cleaning Silicone-Modified Waterborne UV Resin | Seller: Guangzhou Human New Material Science and Technology Co., Ltd | LUV533 is a high-performance, silicone-modified hexafunctional waterborne UV resinengineered to d... | |

| Water-based Soft-Touch Resin for Consumer Electronics | Seller: Guangzhou Human New Material Science and Technology Co., Ltd | Water-based Soft-Touch Resinis an advanced coating material formulated to deliver a luxurious, ve... | |

| Conformal Coatings | Seller: Guangzhou Human New Material Science and Technology Co., Ltd | The conformal coatingsprovide good adhesion to metal, PCB and other substrates after curing at ro... | |

| Metalized & Laser Transfer coating | Seller: Guangzhou Human New Material Science and Technology Co., Ltd | Metallized and laser transfer coatingsare designed with sustainability in mind, ensuring minimal ... | |

| Hydrophilic coatings for Air Conditioner | Seller: Guangzhou Human New Material Science and Technology Co., Ltd | A water-based coating combination applied on the surface of aluminum foil, which forms a layer wi... |