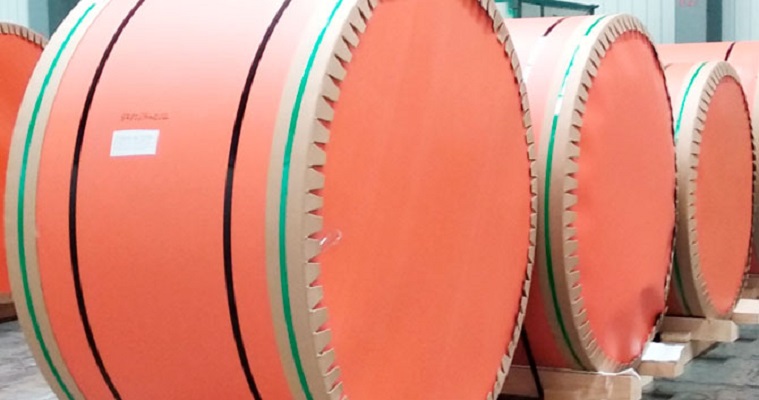

3005 Aluminium Coil

Aluminum 3005 is an aluminum alloy with manganese as its primary alloying element, supplemented with a magnesium addition which makes it stronger than 3003 alloy.

Application of 3005 Aluminium Coil

3005 aluminum coilis often applied for the moist conditions such as air conditioner, refrigerator, bottom of cars, etc. It is also commonly used for building materials or color coated aluminum.

Features of 3005 Aluminium Coil

3005 aluminium coil has good formability, weldability, and corrosion resistance. Used for processing parts that require good formability, high corrosion resistance, good weldability.

Specification of 3005 Aluminium Coil

|

Model Grade |

3005 |

|

Temper |

O/F/H111/H112/H12/H14/H22/H24 |

|

Thickness |

|

|

Size |

As request |

|

Hardness |

More than 28 HB |

|

Alloy or Not |

Alloy |

|

Surface treatment |

Mill finished /brushed/polished |

|

MOQ |

No limited for ready stock |

|

Technology standard |

GB/T 3880/ASTM.B209/EN485 |

CAISC is a professional aluminium sheet roll supplier, we provide aluminum alloy products, aluminium sheet roll, aluminum sheet roll, aluminum roll sheet, aluminum cnc cutting service, etc. If you want to know more, please contact us.

在线联系供应商

Other supplier products

| 6061 Aluminium Tube | 6061 Aluminium Tube Aluminum alloy round tubeis a kind of non-ferrous metal tube, which is made of pure aluminum or aluminum alloy by extrusion an... | |

| Aluminium Checkered Plate | China Alum Checker Plate This alloy aluminum in the main alloy elements as magnesium and silicon, with middle strength, good corrosion resistance,... | |

| 3005 Aluminium Coil | Aluminum 3005 is an aluminum alloy with manganese as its primary alloying element, supplemented with a magnesium addition which makes it stronger t... | |

| 5083 Aluminum Plate | The main alloying element of china 5083 aluminum plateis magnesium, which is a professional anti-rust aluminum plate. Application of 5083 alumin... | |

| Aluminium Foil | Aluminium alloy foilhas excellent sealing, plasticity, and antifouling properties. Aluminum foil is a non-toxic packaging material and the surface ... |