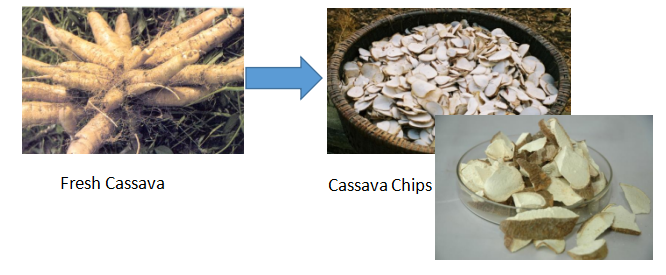

Cassava Chips Machine

Cassava Chips Processing Description and Flowchart:

Cassava chips are one kind of chips or slices made from fresh cassava roots, as snacks or animal feed popular in many countries of West Africa and the Caribbean.Cassava chips drying machineis very important for the production of cassava chips.

Goodway has 27 years of combined experience in the tapioca chips making machine and cassava chips processing machine.

Multiple distinct operations are required in cassava chips processing: washing, peeling, slicing, chips drying and packaging.

We provide below a brief description of the main steps of the cassava chips productionprocess.

Cleaning and Washing Cassava Roots

Wash the fresh cassava roots in clean water to remove the surface mud and sand. It's the first step of cassava chips process and very important for the quality of final cassava chips.

Peeling Cassava Roots

Peeling Cassava Roots

Peel the washed cassava roots to remove the outer brown skin and inner thick cream layer. The water source should be checked regularly to ensure it is not dirty or contaminated.

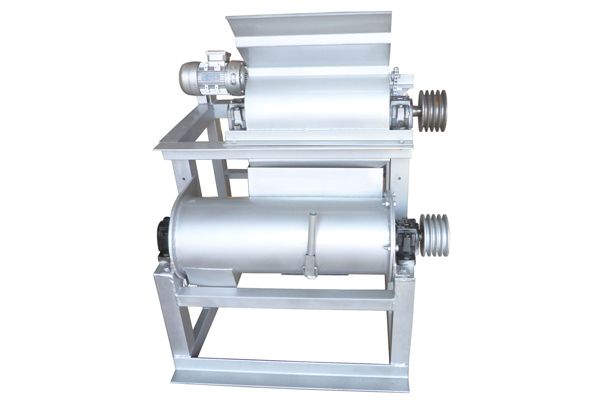

Cutting Cassava Roots into Wet Cassava Chips

Cutting Cassava Roots into Wet Cassava Chips

Cut the peeled cassava roots into chips by the high speed rotating circular cutter blade, then cut the chips into strips by the cross cutter blade.

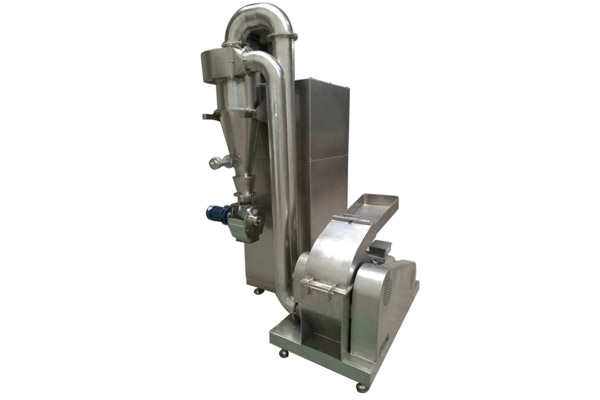

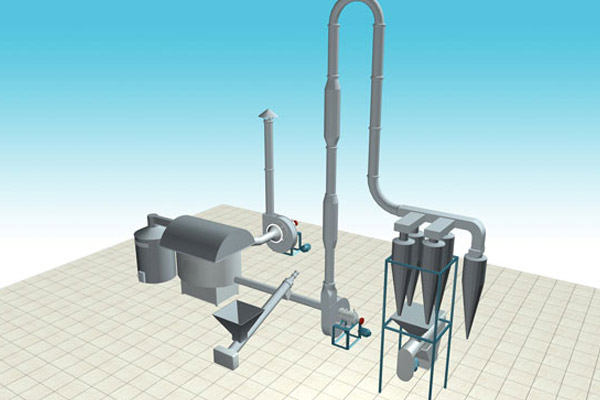

Drying Wet Cassava Chips into Dried Cassava Chips

Drying Wet Cassava Chips into Dried Cassava Chips

Dry the wet cassava chips into dried cassava chips with low moisture content by the principle of heat transfer exchange.

在线联系供应商

Other supplier products

| Cassava Flour Milling Machine | Features of Cassava Flour Milling Machine Processing Capacity: 400-500kgs/hour Application Scope: Milling the coarse powder into fine powder Produ... | |

| Airflow Flash Dryer(Cassava Drying Machine) | Features of Airflow Flash Dryer(Cassava Drying Machine) The starch factory at present normally adopt airflow drying (also called flash dryingor fl... | |

| Cassava Grater Machine(Cassava Grinding Machine) | Grater Machine for Cassava(Cassava Grinding Machine) VIDEO Features of Cassava Grater Machine(Cassava Grinding Machine) Processing Capacity: 3-6T... | |

| Cassava Curved Mesh Crusher 2019 | Features of Cassava Curved Mesh Crusher Processing Capacity: 2-8Tons/hour Application Scope: Crushing the cassava into the slurry and remove the re... | |

| Cassava Vibrating Sieve | Features of Cassava vibro sifter sieves Break the pressed cassava cakes into granules and separate the uniform size granules from the lumps to obt... |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | 卖方: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | 卖方: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |