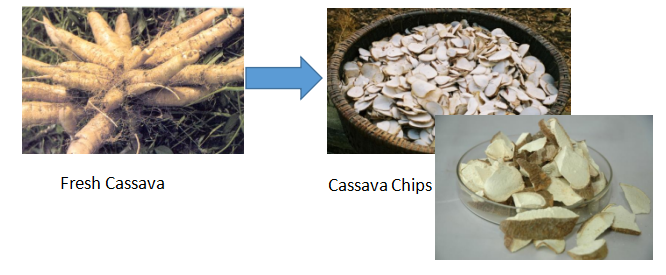

Cassava Chips Machine

Cassava Chips Processing Description and Flowchart:

Cassava chips are one kind of chips or slices made from fresh cassava roots, as snacks or animal feed popular in many countries of West Africa and the Caribbean.Cassava chips drying machineis very important for the production of cassava chips.

Goodway has 27 years of combined experience in the tapioca chips making machine and cassava chips processing machine.

Multiple distinct operations are required in cassava chips processing: washing, peeling, slicing, chips drying and packaging.

We provide below a brief description of the main steps of the cassava chips productionprocess.

Cleaning and Washing Cassava Roots

Wash the fresh cassava roots in clean water to remove the surface mud and sand. It's the first step of cassava chips process and very important for the quality of final cassava chips.

Peeling Cassava Roots

Peeling Cassava Roots

Peel the washed cassava roots to remove the outer brown skin and inner thick cream layer. The water source should be checked regularly to ensure it is not dirty or contaminated.

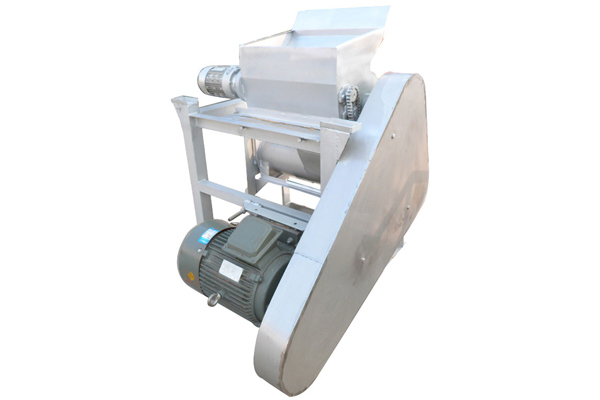

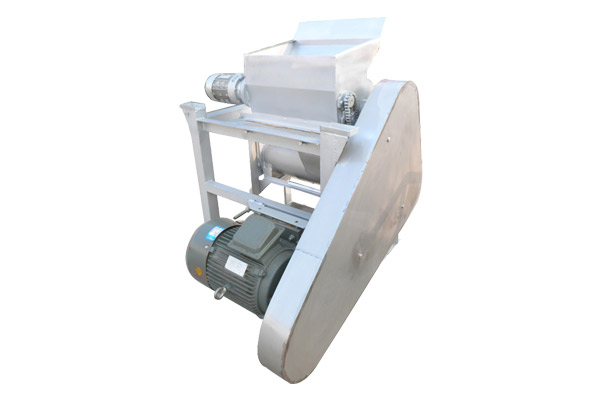

Cutting Cassava Roots into Wet Cassava Chips

Cutting Cassava Roots into Wet Cassava Chips

Cut the peeled cassava roots into chips by the high speed rotating circular cutter blade, then cut the chips into strips by the cross cutter blade.

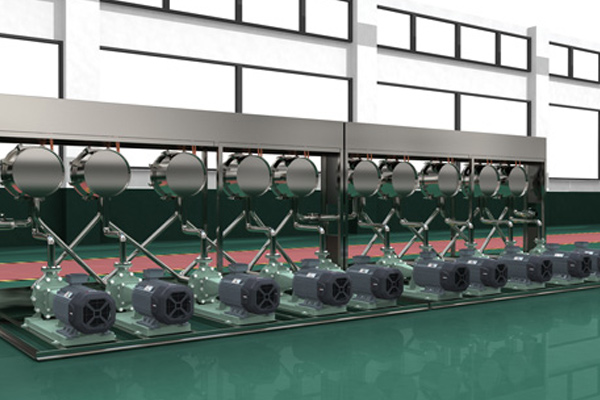

Drying Wet Cassava Chips into Dried Cassava Chips

Drying Wet Cassava Chips into Dried Cassava Chips

Dry the wet cassava chips into dried cassava chips with low moisture content by the principle of heat transfer exchange.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Centrifugal Dewatering Machine | Features of Centrifugal Dewatering Machine Processing Capacity: 1-10Tons/hour Application Scope: Cassava or potato starch dewatering Product Int... | |

| Cassava Processing Machine | As one of cassava processing machines manufacturersand cassava processing machinery suppliers, Goodway can provide the complete set of from cassava... | |

| Cassava Grater Machine(Cassava Grinding Machine) | Features of Cassava Grater Machine(Cassava Grinding Machine) Processing Capacity: 3-6Tons/hour Application Scope: Grating the cassava into the slur... | |

| Cassava Grinding Machine | Features of Cassava Grinding Machine Processing Capacity: 3-6Tons/hour Application Scope: Grating the cassava into the slurry. Product Introduct... | |

| Cassava Starch Hydrocyclone(Extraction Machine) | Features of Cassava Starch Hydrocyclone(Extraction Machine) Cassava Sieving Machine - Starch Hydrocyclone Processing Capacity: 25m3/hour Applica... |

Похожие товары

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Продавец: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Продавец: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... | |

| 3 in1 Decoiler Leveler Feeder | Продавец: Dongguan YouYi Precision Automation Equipment Co., Ltd. | 3 in1 Decoiler Leveler Feeder For Thin Plate(0.3-3.2mm) The 3-in-1 servo feederintegrates four f... | |

| NC Servo Feeder (0.1-3.0mm) | Продавец: Dongguan YouYi Precision Automation Equipment Co., Ltd. | NC Servo Feeder (0.1-3.0mm) Our standard servo feederis engineered for precision coil feeding of... | |

| Uratech 40 Taper CNC Tower – CAT 40 Tool Cart & CNC Tool Holder Storage | Продавец: Uratech USA Inc | TheUratech 40 Taper CNC Toweris the ultimate solution for organizing and protecting your CNC tool... |