Digital Smart Factory

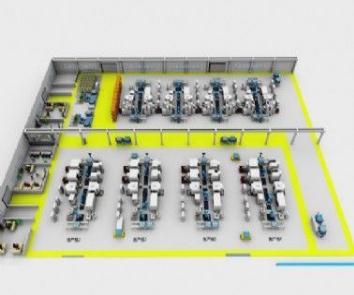

"Digital Factory" technology and system for manufacturers and suppliers to provide a manufacturing process information platform to enable enterprises to the entire manufacturing process design planning, simulation and management, and manufacturing information and the relevant departments in a timely manner , Supplier sharing, in order to achieve virtual manufacturing and concurrent engineering, to ensure the smooth progress of production.

In the automotive industry, digital factory is playing an important role. The shift from product design to manufacturing is one of the most critical steps in the automotive development process. The "digital plant" planning system enables detailed design planning and validation to anticipate all manufacturing tasks while improving quality while reducing design time, Thus accelerating the vehicle development cycle; and can also eliminate waste and reduce the number of resources required to complete a task. In addition, the "digital factory" planning system through a unified data platform to achieve OEM plant, production line suppliers, fixture suppliers and other concurrent engineering.

"Digital Factory" provides a comprehensive manufacturing process management, in the actual production before the computer simulation of the environment to complete all the virtual production process, generated after the "digital factory" verified, the actual production of the necessary process data and Documentation.

Workflow shown in Figure 2, respectively, the following details:

(1) to obtain product data from the design department:

Through the system integration, from the design department of the PDM system automatically download product-related data, including 3D models, assembly relationships, and in the "digital factory" environment for process review, tolerance analysis.

(2) Obtain resource data (2D / 3D) from tooling tools and production department:

Through the system integration, from the enterprise resource library automatically download the relevant resource data; in the "digital factory" environment to establish the relevant project resource library.

(3) process planning:

In the "digital factory" planning module for collaborative planning or import process sector has process information. Process planning, including: the total process plan, details of the process plan, production plans and products, processes, resources and working hours associated with process information.

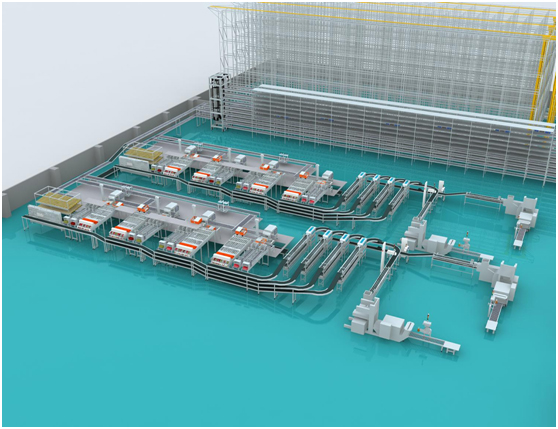

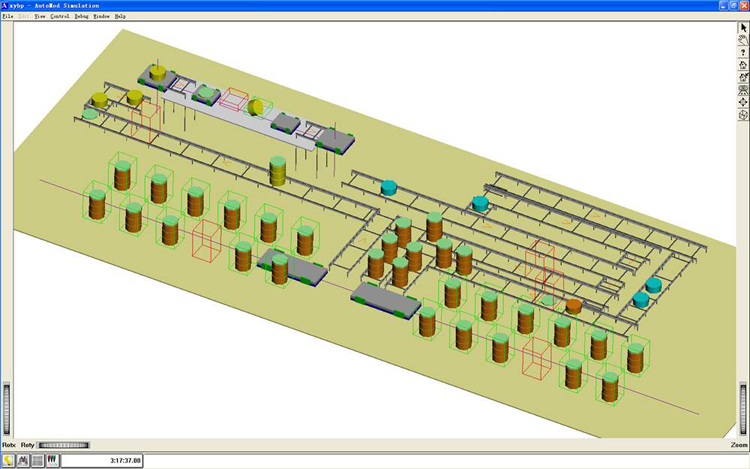

(4) process validation, simulation:

Verify the planning results in the "Digital Plant" engineering module. Process verification, dynamic assembly, station layout verification, line balance, time analysis, ergonomic simulation, plant layout, logistics simulation, robot simulation, NC simulation, stamping simulation, PLC simulation and quality inspection.

(5) Customized output:

Through the system integration and customization development, the output process execution file; through system integration and custom development, output production, procurement, bidding, maintenance, training and other information or data transmission to the existing CAPP system.

The entire process has always involved the automotive OEMs and production line suppliers, which requires companies to use the same platform to ensure the realization of concurrent engineering and unified data specifications, in order to achieve parallel factories. The "digital factory" solutions used by different global automotive planning systems (US, European, Japanese, etc.) have different modes and localization characteristics due to the different modes of cooperation, control and balance.

在线联系供应商

Other supplier products

| Digital Smart Factory | "Digital Factory" technology and system for manufacturers and suppliers to provide a manufacturing process information platform to enable enterpr... | |

| Logistics distribution management | 1、Logistics and distribution management system for the present and the future of the complex and changeable automated production line material ha... | |

| System simulation | It is a very effective method to evaluate efficiency by applying simulation technology and calculation method to logistics system. At the stage o... | |

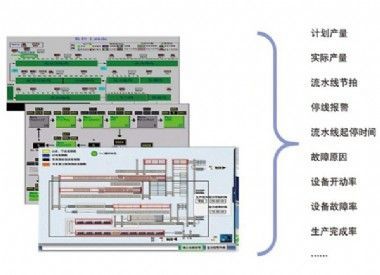

| JG-MES PMC | PMC JG-MES system: an overviewPMC system will be used to monitor production status in real time, measure and track the work of pr... | |

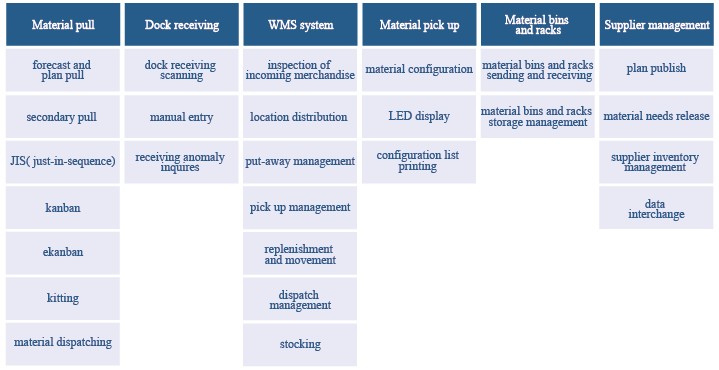

| EW-MES MMM | JG-MES Materials ManagementModule JG-MES materials management module mainly realize production line JIT / JIS material pull, w... |

Same products

| Made in China Pressure Switch HC0622-24 for thermal power plant | 卖方: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Made in China Pressure Switch HC0622-24 for thermal power plant YOYIK professional production an... | |

| Gas Torch | 卖方: Ningbo Shuai Xian Regulator Co., Ltd | Introduction Set packed with hoses, regulator arm support of gas Torch Gas blow torchSpecific... | |

| Gas Regulator Connector | 卖方: Ningbo Shuai Xian Regulator Co., Ltd | barbecue gas connectorused in conjunction with a cylinder valve to deliver an unreduced pressure ... | |

| Gas Regulator Accessories, Gas Hose Fitting & Torch | 卖方: Ningbo Shuai Xian Regulator Co., Ltd | Integrated Gas Technologies(IGT®) supplies gas regulator outlet fittinglike gas regulator hos... | |

| Gas Regulator | 卖方: Ningbo Shuai Xian Regulator Co., Ltd | Integrated Gas Technologies(IGT®) is a global gas control equipment company founded 2006 exce... |