Wet leakage current test system of photovoltaic module

The Wet Leakage Current Test System is designed for high-precision evaluation of insulation resistance and leakage current in photovoltaic modules under simulated wet conditions. It replicates real-world rain, dew, and irrigation scenarios while providing accurate temperature control and corrosion-resistant construction, ensuring reliable PID and insulation defect testing.

Application

(1) Wet insulation resistance measurement of framed and frameless PV modules

(2) Detection of leakage currents to evaluate PID (Potential Induced Degradation) risk

(3) Qualification testing per IEC 61215 and UL 61730 standards

(4) Laboratory testing of module materials, encapsulants, and junction boxes

(5) R&D of PV module waterproofing and sealing technologies

Standards

(1) IEC 61215 – Terrestrial Photovoltaic (PV) Modules: Design Qualification and Type Approval

(2) UL 61730 – Safety Standard for Photovoltaic Modules

(3) ISO 17025 – General Requirements for the Competence of Testing and Calibration Laboratories

(4) CE Certification – Conformité Européenne

(5) Optional: IEC 60529 – Degrees of Protection Provided by Enclosures (IP Code)

Features

IEC 61215 Compliance: Maintains 22±3°C for consistent wet insulation resistance measurements.

Precise Liquid Resistivity: <3,500 Ω·cm ensures accurate leakage current detection per standard requirements.

Multi-Directional Spray Simulation: 360° adjustable nozzles with 0–10 bar flow for customizable rain/dew exposure.

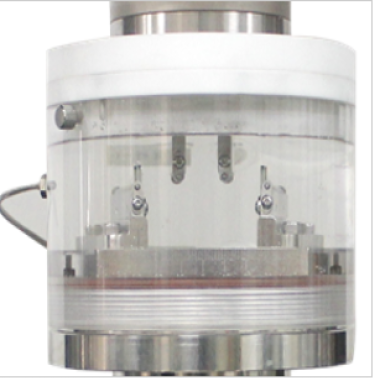

Corrosion-Resistant Design: 15mm Plexiglass tank and 316L stainless steel fittings resist salt spray and UV exposure.

Safety Features: 30mA GFI and door interlock system for operator protection during wet cycles.

Smart Data Acquisition: 16-bit ADC captures microamp-level leakage currents; AI diagnostics flag insulation defects.

User-Friendly Operation: Dual-zone temperature control, 7” touchscreen HMI, remote monitoring, and self-cleaning protocols.

Modular Testing: Expandable from single-module to 10-module parallel testing.

Parameters

| Parameter | Specification |

|---|---|

| Test Tank Dimensions | 2,100 mm × 1,000 mm × 250 mm (W×D×H) |

| Tank Material | 15 mm Cast Acrylic (Plexiglass) |

| Temperature Range | 15°C to 40°C (operational) |

| Temperature Stability | ±0.5°C (at 22°C setpoint) |

| Liquid Resistivity | <3,500 Ω·cm (deionized water recommended) |

| Spray Pressure | 0–10 bar (adjustable) |

| Flow Rate | 0–15 L/min (per nozzle) |

| Power Supply | 230V AC, 50/60Hz (single-phase) |

| Dimensions (W×D×H) | 2,500 mm × 1,200 mm × 1,500 mm |

| Weight | 350 kg (net) / 450 kg (gross) |

Accessories

(1) PV module test fixtures (4 pcs, adjustable for frameless/framed modules)

(2) Insulated test leads with alligator clips (10 pcs)

(3) Software Suite: LeakTest Pro license (Windows/Linux), 1-year cloud-based I-V curve analyzer

(4) Calibration & Safety: NIST-traceable conductivity meter, emergency eyewash station (wall-mounted)

(5) Maintenance Kit: Spare acrylic tank seal, nozzle gaskets, non-corrosive tank cleaning solution

(6) Documentation: Multilingual quick-start guide (printed + digital), compliance certificates for IEC/UL/ISO standards

Test Procedures

Install PV module on test fixture and connect insulated leads to module terminals.

Fill tank with deionized water and set liquid resistivity below 3,500 Ω·cm.

Configure chamber and water temperature via HMI to 22±3°C.

Adjust nozzle orientation and spray pressure to desired testing conditions.

Initiate test sequence; system sprays water while measuring leakage current and recording data.

Monitor results in real-time through HMI or remote software interface.

Upon completion, stop spray, drain water using automated self-cleaning system, and safely remove the PV module.

Export recorded data for analysis and reporting.

Maintenance Information

Clean tank surfaces, nozzles, and PV module fixtures regularly to prevent residue buildup.

Replace acrylic seals, nozzle gaskets, and test leads as needed.

Periodically calibrate conductivity meters and data acquisition channels.

Verify GFI and door interlock functionality before each test cycle.

Maintain tank and equipment in a dry environment when not in use.

在线联系供应商

Other supplier products

| Bio-absorbable Internal Fixation Plates and Screws Test device | Standard YY/T 0509-2009 (China): Specifies mechanical testing protocols for orthopedic plates/screws made of hydrolyzable polymers, including axia... | |

| Micro Rapid Closed Cup Flash Point Tester | Reference Standards: SH/T 0768. SN/T 3077.1. DL/T 1354. ASTM D6450 SN/T 3077.2. ASTM D7094 GB/T 261. GB/T 21615. ASTM D93 GB/T 5208. GB/T 21790. A... | |

| Photovoltaic module insulation resistance tester | The Photovoltaic Module Insulation Resistance Tester is a precision instrument designed for simultaneous measurement of insulation resistance and l... | |

| UV curing light box | Standard ISO 10977: Adheres to industrial standards for UV curing of adhesives and coatings. ASTM E3022: Meets requirements for radiometric measu... | |

| Flammability test furnace for building materials | Product Introduction Touch screen control building materials flammability test furnace adopts stainless steel box, is in the old JCK-2 products ba... |

Same products

| Air Permeability Tester STD- F8 | 卖方: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... | |

| Surface Performance Tester STD-FB4 - A | 卖方: Standard International Group (HK) Limited | Introduction TheSurface Tester analyzes finger movements-particularly, strokes-performed by arti... | |

| Compression Tester STD - FB3 - A | 卖方: Standard International Group (HK) Limited | TheCompression Tester analyzes hand movements-particularly, pushing with a finger-performed by ar... | |

| Single - Strand Bending Tester STD - FB2 - SH | 卖方: Standard International Group (HK) Limited | Standards ASTM A370. ASTM A416. ISO6934.4 The Single Fiber Bending Tester makes it possible to ... | |

| Bending Tester STD- FB2 - S | 卖方: Standard International Group (HK) Limited | Compliance Standards ASTM D790 (Plastics Flexural Properties) ISO 178 (Flexural Strength of Rig... |