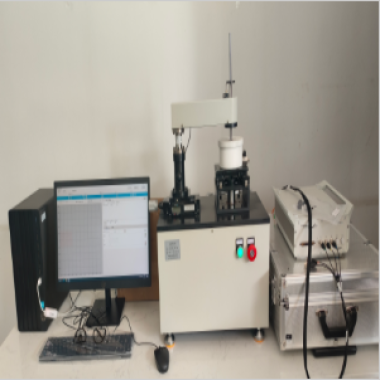

Photovoltaic module wire tube bending testing machine

The Photovoltaic Module Wire Tube Bending Testing Machine is designed to evaluate the mechanical durability and fatigue resistance of PV module output cables and protective conduits under repeated bending stress. The system simulates long-term cable flexing conditions to verify compliance with IEC safety requirements, ensuring reliable electrical connections throughout the service life of photovoltaic modules.

Application

(1) Bending fatigue testing of photovoltaic module output cables

(2) Mechanical durability verification of wire tubes and protective conduits

(3) Safety qualification testing for PV junction box cable assemblies

(4) Accelerated lifetime testing for PV cable management systems

(5) Quality control and compliance verification in PV module production

Standards

(1) IEC 61730-2:2004 – Photovoltaic (PV) Module Safety Qualification – Requirements for Testing

(2) CE Certification (Conformité Européenne)

Features

(1) IEC-Compliant Bending Simulation: Accurately reproduces long-term cable flexing conditions defined in IEC 61730-2.

(2) Precision Motion Control: High-resolution frequency and angle control ensures consistent and repeatable bending cycles.

(3) Automatic Failure Detection: Test stops immediately when abnormal torque, cracking, or mechanical failure is detected.

(4) User-Oriented Operation: 7” HD touchscreen with intuitive parameter setting and real-time force–displacement visualization.

(5) Self-Calibrating System: Automatic zeroing and linearity verification before each test cycle.

(6) Robust Mechanical Structure: Stainless steel frame with epoxy coating for long-term stability and corrosion resistance.

(7) Data Traceability: Complete recording of cycle count, bending force, and failure point for quality audits.

Parameters

| Parameter | Specification |

|---|---|

| Frequency Range | 0–120 Hz (adjustable) |

| Spindle Speed | N RPM = Frequency (Hz) / 60 |

| Timing Range | 1–9,999 seconds (1–166.65 minutes) |

| Force Resolution | 0.1 N (maximum capacity 10 kgf) |

| Bending Angle Accuracy | ±1° (rotary encoder feedback) |

| Power Supply | 220V AC, 50/60Hz, single-phase |

| Dimensions | 500 mm (W) × 400 mm (D) × 600 mm (H) |

| Weight | 45 kg (net) / 60 kg (gross) |

Accessories

(1) Testing Kit: 10× conduit clamps (2–20 mm diameter range)

(2) Calibration Tools: 5× calibration weights (1 N–10 N)

(3) Software Suite: BendTest Pro license (Windows/macOS), 1-year cloud fatigue analysis access

(4) Calibration & Safety: NIST-traceable torque wrench, insulated gloves (Class 0, 3 pairs)

(5) Maintenance Kit: Spare drive belts, bearings, and non-corrosive cleaning solution

(6) Documentation: Multilingual quick-start guide (printed and digital), compliance certificates

Test Procedures

(1) Secure the PV cable or wire tube specimen using the appropriate conduit clamps.

(2) Set bending frequency, timing, and angle parameters via the touchscreen HMI.

(3) Start the test cycle and monitor real-time force and bending angle feedback.

(4) Allow the system to run until the preset cycle count is reached or automatic failure detection is triggered.

(5) Record and export test data, including total cycles, peak force, and failure point.

Maintenance Information

(1) Inspect clamps, drive belts, and bearings regularly for mechanical wear.

(2) Clean the frame and moving components to prevent dust accumulation.

(3) Verify force sensor and angle encoder calibration periodically.

(4) Check emergency stop and overload protection functions before routine operation.

(5) Store the machine in a dry environment to maintain long-term measurement stability.

在线联系供应商

Other supplier products

| 5kN Universal Testing Machine丨5kN Universal Tester | Product Introduction This series of testing machines realizes the automatic control of the test process, data acquisition and analysis through the... | |

| Electrochemical Corrosion and Wear Testing Machine | Electrochemical corrosion and wear testing machines are widely used in materials science, mechanical engineering, electronic engineering, aerospace... | |

| Humidity Environmental Test Chamber | Features and Benefits 1.Wide Humidity & Temperature Range Offers precise control over humidity from 20% to 98% RH and temperature from -70&de... | |

| Standard light source sample table | Standards ISO 3664:2009: Meets international standards for graphic arts and photography view conditions. DIN 6173-2: European norm for illuminant... | |

| Tracking indices of solid insulating materials Test Machine ,IEC60112 | Introduction This tester is in accordance with IEC60112 standard . It is suitable for lighting, low voltage electrical equipment, household appl... |

Same products

| Air Permeability Tester STD- F8 | 卖方: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... | |

| Surface Performance Tester STD-FB4 - A | 卖方: Standard International Group (HK) Limited | Introduction TheSurface Tester analyzes finger movements-particularly, strokes-performed by arti... | |

| Compression Tester STD - FB3 - A | 卖方: Standard International Group (HK) Limited | TheCompression Tester analyzes hand movements-particularly, pushing with a finger-performed by ar... | |

| Single - Strand Bending Tester STD - FB2 - SH | 卖方: Standard International Group (HK) Limited | Standards ASTM A370. ASTM A416. ISO6934.4 The Single Fiber Bending Tester makes it possible to ... | |

| Bending Tester STD- FB2 - S | 卖方: Standard International Group (HK) Limited | Compliance Standards ASTM D790 (Plastics Flexural Properties) ISO 178 (Flexural Strength of Rig... |