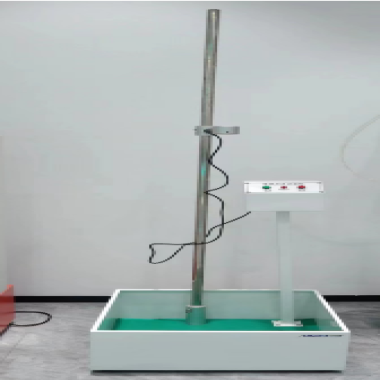

Safety Helmets Wearing Stability Tester

The Safety Helmets Wearing Stability Tester is designed to evaluate helmet retention and fit under dynamic conditions, simulating real-world head movements and impact scenarios. It provides precise measurement of helmet stability, retention forces, and deformation, ensuring compliance with international and national safety standards. The instrument is suitable for production quality control, R&D, and certification testing of industrial, sports, and cycling helmets.

Application

This tester is suitable for assessing helmet fit stability and retention performance for:

(1) Industrial helmets used in construction, manufacturing, and mining

(2) Cycling helmets for road, mountain, and urban riding

(3) Sports helmets for skating, climbing, skiing, and other high-mobility activities

(4) Motorcycle and E-bike helmets for rider safety certification

(5) R&D of custom helmet designs with adjustable retention systems

Standards

The tester complies with the following standards:

(1) GB 811-2022 – Safety Helmets: General Technical Requirements

(2) GB 24429-2009 – Sports Helmets: Requirements and Test Methods

(3) GB/T 2812 – Safety Helmets: Test Methods

(4) ISO 6220-2 – Industrial Safety Helmets: Fit Stability

(5) CE Certification (Conformité Européenne)

Features

Multi-Standard Compliance: Simulates extreme lateral forces and evaluates retention system integrity.

High-Precision Measurement: 0.1kg load resolution and 0.1N force sensor accuracy for repeatable results.

Dynamic Tilt Testing: 360° tilt mechanism reproduces real-world head movements.

User-Friendly Operation: 7” touchscreen HMI with preloaded GB/T 2812 sequences and real-time force graphs.

Quick-Swap Helmet Clamp: Rapid replacement of helmets for high-throughput labs.

Safety Systems: Dual interlocks and overload protection prevent accidental activation and sensor damage.

Self-Calibrating System: Auto-tare and linearity checks before each test.

Durable Construction: Aircraft-grade aluminum frame and corrosion-resistant sensors ensure long-term reliability.

Parameters

| Parameter | Specification |

|---|---|

| Impact Weight | 10.0kg ±0.1kg (stainless steel) |

| Initial Load | 3.0kg ±0.1kg (adjustable) |

| Release Method | Manual lever with safety interlock |

| Tilt Range | 0–360° (1° resolution) |

| Force Sensor | 0–500N range, 0.1N resolution |

| Data Acquisition | 16-bit resolution, 1,000Hz sampling |

| Power Supply | 220V AC, 50/60Hz (single-phase) |

| Dimensions | 800mm (W) × 600mm (D) × 1,500mm (H) |

| Weight | 150 kg (net) |

Accessories

(1) Testing Kit: 2x universal helmet clamps (adjustable for 50–65 cm heads), 5x calibration grade load cells (10N–500N)

(2) Software Suite: License key for StabilityTest Pro (Windows/macOS), 1-year free access to cloud-based fit analysis tools

(3) Calibration & Safety: NIST-traceable force gauge, 2x safety glasses (EN 166 rated), 1x face shield

(4) Maintenance Kit: Spare accelerometers and load cells, machine cleaning solution (non-corrosive)

(5) Documentation: Multilingual quick-start guide (printed + digital), compliance certificates for GB/ISO standards

Test Procedures

Secure the helmet in the universal clamp and adjust to the correct head circumference.

Select the wearing stability test mode via the touchscreen HMI.

Set impact weight and initial load according to test requirements.

Adjust tilt angle and initiate the motorized tilt stage.

Monitor real-time force graphs and retention performance during rotation.

Export data as PDF or CSV for certification or R&D analysis.

Repeat tests for additional helmets as required.

Maintenance Information

Inspect helmet clamps, tilt mechanism, and load cells regularly; replace worn parts.

Verify calibration of force sensors every six months using NIST-traceable instruments.

Clean frame, clamps, and sensors with non-corrosive solutions to maintain accuracy.

Store the tester in a dry, temperature-controlled environment to prevent corrosion.

Follow standard electrical safety procedures during operation and maintenance.

在线联系供应商

Other supplier products

| Battery Test Chamber丨Battery Test mechine | Features and Benefits 1.Wide temperature range (-70℃ to +150℃),temperaturefluctuation ≤±0.5℃, Humidity control accuracy±2%RH,th... | |

| Battery diaphragm permeability tester | Meet the standard: GB/T458. ISO536/2. QB/T1667. GB/T23227. ISO2965. YC/T172. GB/T12655. S05636/3. IS05636/5. GB/T20042.7-2014. GB/T36363-2018. et... | |

| Falling ball impact testing machine | Product Introduction: Falling ball impact tester is suitable for testing the fastness of plastic, ceramic, acrylic, glass fiber and other material... | |

| Industrial Oven for Batteries | Features and Benefits 1.Real-time temperature monitoring, temperature range can be customized to +1000 ° C, +1200 ° C, accuracy ±0.... | |

| Solids Spontaneously Igniting Tester | Conforms to the UN Recommendations on the Transport of Dangerous Goods - Manual of Tests and Criteria 33.3.1.4 Test N.2: Test Methods for Pyrophori... |

Same products

| Air Permeability Tester STD- F8 | 卖方: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... | |

| Surface Performance Tester STD-FB4 - A | 卖方: Standard International Group (HK) Limited | Introduction TheSurface Tester analyzes finger movements-particularly, strokes-performed by arti... | |

| Compression Tester STD - FB3 - A | 卖方: Standard International Group (HK) Limited | TheCompression Tester analyzes hand movements-particularly, pushing with a finger-performed by ar... | |

| Single - Strand Bending Tester STD - FB2 - SH | 卖方: Standard International Group (HK) Limited | Standards ASTM A370. ASTM A416. ISO6934.4 The Single Fiber Bending Tester makes it possible to ... | |

| Bending Tester STD- FB2 - S | 卖方: Standard International Group (HK) Limited | Compliance Standards ASTM D790 (Plastics Flexural Properties) ISO 178 (Flexural Strength of Rig... |