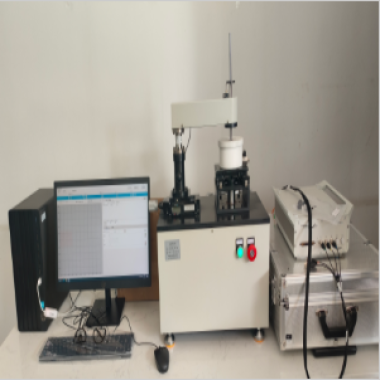

Full Notch Creep Tester

This testing machine is used to test the environmental stress cracking performance of plastic materials. The equipment features touchscreen operation, weight loading, and ensures independent operation of each workstation, uniform temperature distribution, and stable and consistent test results. In addition, a water level monitoring function alerts the operator when the water level is too low.

Applications

1. Plastics/Piping Industry: Testing the high-temperature creep fracture behavior of pipe materials such as PE and PPR to verify long-term service reliability (e.g., water supply and gas pipelines);

2. Automotive Industry: Evaluating the creep stability of plastic/metal components under high-temperature conditions around the engine and exhaust system;

3. Aerospace/Electronics: Verifying the creep resistance of composite materials and electronic packaging materials in high-temperature environments to ensure long-term equipment operation;

4. Chemical/Energy Industry: Testing the creep fracture strength of materials used in chemical equipment and energy storage devices in high-temperature media to meet industrial safety requirements;

5. Materials Research and Development: Screening high-temperature suitable materials, optimizing material formulations and processes, and providing long-term performance data support.

Standards

ISO 16770: Exclusively designed for full-notch creep testing (FNCT) of thermoplastics under sustained stress.

ASTM D2990: Configurable for tensile, compressive, and flexural creep testing of polymers and composites.

Features

1. Uncompromising Precision

Independent 6-Zone Control: Each station operates with ±1% force accuracy (0–2.000N) and ±0.1°C temperature stability.

Hybrid Loading System: Combines motorized force application with manual fine-tuning via touchscreen-guided weights.

2. Versatile Testing Environments

Dual Bath Compatibility: Switch between water (up to 95°C) and oil (up to 150°C) baths for high-temperature polymer analysis.

Expanded Force Capacity: Upgradeable to 4.000N max. load per station for heavy-duty applications.

3. Intelligent Monitoring

Auto-Level Sensing: Real-time solution height detection prevents test interruptions from evaporation or leaks.

Visual Alerts: Touchscreen displays color-coded status indicators for all stations.

4. Future-Ready Design

Modular Architecture: Add stations or upgrade controllers without replacing the entire system.

Multi-Language Interface: Operate in English, German, Chinese, or Spanish.

Technical Parameters

| Specification | Details |

|---|---|

| Stations | 6 fully independent test positions |

| Force Range (per station) | 0–2.000N (standard) / 0–4.000N (optional) |

| Temperature Control | Water: 40–95°C |

| Force Accuracy | ±1% FS (0.5% with calibration kit) |

| Power Supply | 220V/50Hz (110V/60Hz available) |

| Bath Capacity | 15L per station (90L total) |

| Dimensions (W×D×H) | 1.800mm × 750mm × 1.650mm |

| Weight | 380 kg (net) |

Accessoriess

Test Media:

High-temperature silicone oil (150°C max.)

Deionized water reservoir with auto-refill.

Sample Fixtures:

Self-tightening grips for notched specimens (ISO 16770 compliant).

Flat dog-bone clamps for ASTM D2990 testing.

Software Bundle:

CreepVision Pro™: AI-assisted strain analysis with Weibull modulus calculation.

LabShare Cloud: Remote monitoring for up to 50 concurrent users.

Calibration Kit:

NIST-traceable force gauge and thermocouple set.

Extended Warranty:

5-year comprehensive coverage for load cells and controllers.

Test Procedures

1. Pre-test preparation

Check that the instrument's power supply, heating system, and loading mechanism are functioning correctly. Calibrate the temperature and load sensors. Clean the test chamber and fixtures of any debris. Ensure that there is sufficient high-temperature medium (such as heat transfer oil).

2. Sample preparation and installation

Prepare samples with full notches according to the standard, and record basic information such as sample dimensions and notch parameters. Fix the sample onto the special fixture, ensuring that the notch direction is consistent with the force direction, and that the clamping force of the fixture is uniform to prevent sample misalignment.

3. Parameter setting

Set the test temperature, constant load value, and holding time (or fracture termination condition) through the control panel. Set the data acquisition frequency. After confirming that the parameters meet the test standard (e.g., ISO 16770), save the settings.

4. Starting the test

Close the test chamber door, start the heating system, and after the chamber temperature stabilizes to the set value and is maintained for a period of time, start the loading program. The instrument will automatically apply a constant load and start timing, recording creep deformation data in real time.

5. Test monitoring

During operation, monitor the temperature and load stability, observe the sample deformation and crack propagation, and promptly handle any abnormal alarms to ensure continuous testing.

6.Test completion and cleaning

After the sample fractures or reaches the set duration, the instrument automatically unloads and shuts down. After the test chamber cools down to room temperature, open the chamber door, remove the sample, and record data such as fracture time and deformation amount. Clean the fixtures and test chamber, turn off the instrument power, and prepare the test report.

在线联系供应商

Other supplier products

| Air Permeability Tester STD- F8 | The Air Permeability Tester is designed to quickly and accurately measure the breathability and permeability of a wide range of samples, from those... | |

| Face Mask Tensile Tester | Introduction: The test machine uses the integrated structure of the motor and the speed control system to drive the synchronous belt deceleration ... | |

| Carpet Static Electricity Test device | Test Principle When a person walks on the inspected carpet wearing the shoes specified in the standard and following the prescribed walking patter... | |

| Electrochemical Corrosion and Wear Testing Machine | Electrochemical corrosion and wear testing machines are widely used in materials science, mechanical engineering, electronic engineering, aerospace... | |

| American European bending tester | Test Purpose: To determine if metal wires in children's products bend or break under stress, creating sharp edges or points that pose choking or i... |

Same products

| Air Permeability Tester STD- F8 | 卖方: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... | |

| Surface Performance Tester STD-FB4 - A | 卖方: Standard International Group (HK) Limited | Introduction TheSurface Tester analyzes finger movements-particularly, strokes-performed by arti... | |

| Compression Tester STD - FB3 - A | 卖方: Standard International Group (HK) Limited | TheCompression Tester analyzes hand movements-particularly, pushing with a finger-performed by ar... | |

| Single - Strand Bending Tester STD - FB2 - SH | 卖方: Standard International Group (HK) Limited | Standards ASTM A370. ASTM A416. ISO6934.4 The Single Fiber Bending Tester makes it possible to ... | |

| Bending Tester STD- FB2 - S | 卖方: Standard International Group (HK) Limited | Compliance Standards ASTM D790 (Plastics Flexural Properties) ISO 178 (Flexural Strength of Rig... |