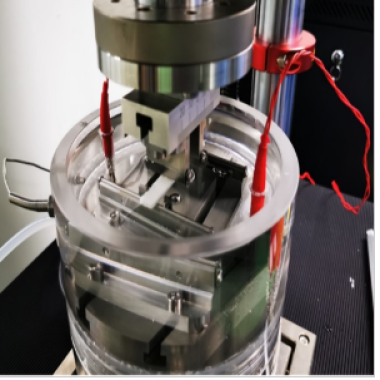

Catheter Flexibility Tester

The Catheter Flexibility Tester utilizes a control system combining a PLC and an industrial computer, along with a color touch screen interface. It has a force range of 0-10 kg and an accuracy of 0.1%. The device features fully automatic pneumatic catheter compression and is suitable for guidewire flexibility and three-point bending tests. Its main technical parameters, including force range, compression speed, and guidewire span, can all be set on the touch screen. This equipment is used to test the flexibility and stiffness of catheters under different conditions, and is characterized by its ease of operation and accurate testing.

Applications

The catheter flexibility tester is mainly used to evaluate the flexibility and durability of catheters or guidewires during bending or twisting processes. This equipment is widely applied in medical, industrial and other fields to ensure the safety and reliability of catheters during use. In the medical field, it is particularly suitable for evaluating the flexibility and durability of medical catheters such as blood vessel catheters, urinary catheters, and biliary catheters, ensuring that they will not cause harm to patients during use. In the industrial field, it can be used to assess the flexibility of catheters transporting fluids, gases and other media in different environments, ensuring their good performance during use. In addition, in fields such as aviation and automotive, the catheter flexibility tester is also used to evaluate the flexibility and durability of catheters under different temperature and pressure conditions.

Standards

ISO 10555 -Intravascular catheters- Sterile and single-use catheters

ISO 11o70- Catheter introducers, dilators, and guidewires

ASTM F2394-Guidewire mechanical property evaluation

ASTM F2908- Stiffness and flexibility of guidewires

ISO 178:2oo1 -Flexural properties of plastics (applicable to catheter materials)

Features

7-inch touchscreen interface with programmable test parameters and intuitive controls

Real-time force vs. displacement data acquisition with automated reporting

Dual-system control for independent force and displacement parameter setting

High-precision ball screw drive and guide mechanism for smooth operation

O.5% FS force sensor accuracy with resolution up to O.01 N

Supports catheter diameters up to 3.3 mm (customization available)

Advanced displacement control with O.1 mm accuracy

Pneumatic clamping system designed for fast, secure catheter mounting

Stores up to 1oo,ooo test records, supports audit trails and data export

Includes Rs232 interface and micro printer for traceable output

Technical Parameters

| Parameter | Specification |

|---|---|

| Testing Range (Force Range) | Usually 0 - 10 kilograms or more, depending on the tester's model and specifications |

| Testing Stroke | Varies in vertical & horizontal directions; e.g., vertical stroke: 0 - 300mm, horizontal stroke: 0 - 700mm |

| Testing Speed | - Press-down Speed: Adjustable within 0 - 300mm/min- Wire-drawing Speed (for applicable testers): 0 - 500mm/min or faster |

| Catheter Clamping Method | Usually adopts pneumatic or mechanical clamping, ensuring the stability and accuracy of the catheter during testing |

| Control System | Adopts PLC control system (high precision & stability); operation interface may be equipped with a color touch screen for convenient setting and operation |

Accessoriess

Main unit, computer, horizontal traction module, pneumatic gripper, 7-inch color touch screen

Test Procedures

1. Insert the intervention catheter into the test pulley system and secure it, ensuring the correct spacing.

2. Adjust the vertical spacing of the test pulleys to maintain a constant test distance.

3. Connect one end of the catheter to the traction head, ensuring the traction head guides the catheter at a constant speed.

4. Monitor the force value change curve during the test using computer software.

在线联系供应商

Other supplier products

| Thermal cycle wet freezing testing machine | Standard IEC 61215: Terrestrial Photovoltaic (PV) Modules – Design Qualification and Type Approval UL 1073: Standard for Safety for Enclosu... | |

| Bottle Wall and Bottom Thickness Tester | The wall and bottom thickness tester for bottles is a measuring instrument widely used in the pharmaceutical, food, cosmetics, and other industries... | |

| Absorbable Bone - connecting Plates Four - point Bending Tester | Standard ASTM F2119: Standard test method for constant load testing of bioabsorbable screws and washers, applicable to bending performance evalu... | |

| Artificial turf wear tester | Standard FIFA Quality Programme: Exceeds 2015/2016 handbook requirements for artificial turf abrasion resistance testing. EN 15330-1: European st... | |

| Incline Impact Tester | The Incline Impact Tester is designed to evaluate the impact resistance of products, packaging, and transport systems under controlled oblique load... |

Same products

| Air Permeability Tester STD- F8 | 卖方: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... | |

| Surface Performance Tester STD-FB4 - A | 卖方: Standard International Group (HK) Limited | Introduction TheSurface Tester analyzes finger movements-particularly, strokes-performed by arti... | |

| Compression Tester STD - FB3 - A | 卖方: Standard International Group (HK) Limited | TheCompression Tester analyzes hand movements-particularly, pushing with a finger-performed by ar... | |

| Single - Strand Bending Tester STD - FB2 - SH | 卖方: Standard International Group (HK) Limited | Standards ASTM A370. ASTM A416. ISO6934.4 The Single Fiber Bending Tester makes it possible to ... | |

| Bending Tester STD- FB2 - S | 卖方: Standard International Group (HK) Limited | Compliance Standards ASTM D790 (Plastics Flexural Properties) ISO 178 (Flexural Strength of Rig... |