Tunnel Oven

Tunnel Oven

Structure: The equipment is composed of electrical control system, mechanical transmission system, skeleton system, electric heating system, food delivery system, exhaust ventilation system, etc .

Tunnel oven Specifications:

|

Spec |

Tray size (mm) |

Inner width (mm) |

Inner height (mm) |

External width (mm) |

|

2 trays |

600*400 |

1450 |

210 |

2375 |

|

3 trays |

600*400 |

2050 |

210 |

2975 |

|

4 trays |

600*400 |

2650 |

210 |

3575 |

|

5 trays |

600*400 |

3250 |

210 |

4175 |

|

6 trays |

600*400 |

3850 |

210 |

4775 |

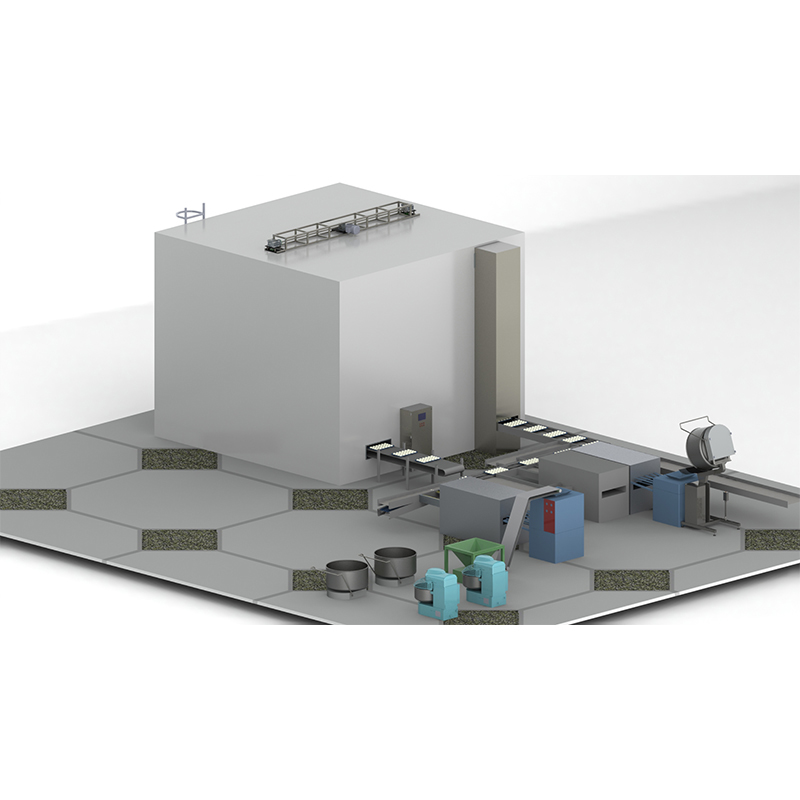

We can customized the length and width of the tunnel oven according to the customer's factory layout and capacity output requirements.

Suitable for loaf toast bread,hamburger buns,hot dog,baguette,croissant,cakes,biscuit,pastry,etc.

1) Insulation System:

A: Using rockwool insulation hybrid cotton,take access method for modular,more full of cotton insulation insulation properties, device power consumption to a minimum.

B: The inner wall of the oven used in all high reflection efficiency 1.5mm thick and 304 stainless steel bore, ensure the furnace during baking heat loss to a minimum.

2) Drive section:

A: The transport conveyor is the chain plate form, it use Hangzhou Donghua chain belt(European technology, customized professional manufacturers),advantages of low noise, wear-resistant high temperature of 500 degrees, chain material collected 40Cr alloy materials, after tested, ultimate tensile load reaches 100KN longer life, better stability, give customers more peace of mind.

B: Chain plate with hot rolled plate bending from 3.0, surface appearance, high strength, flexural resistance, proper storage of heat, stable transfer amount fiery end, the furnace temperature equilibrium. Four bolt connection.

C: SEW reducer and matching motor powered, frequency stepless speed can be precisely controlled by the baking time, good acoustics, high stability.

D: Conveyor using 65Mn spring tension way, the flexibility to automatically adjust the tightness of the conveyor belt, the chain operated more in line with the requirements of mechanics, running more smoothly.

3) Exhaust systems:

A: According to the arrangement of the baking process food inflation hair, stereotypes dehydration, color three stages, exhaust pipe arranged in three stages.

B: Exhaust hood using natural air ejector exhaust hood design, ensure reasonable nature row tide, using exhaust hood exhaust pipe design, not directly connected to the furnace smoke pipe tobacco pipe, but connected to the exhaust hood, around of exhaust hood may enter natural air. Because the furnace temperature and altitude smoke tube forming hot outside temperature difference stress, continuous upward flow of hot air, exhaust hood external natural cold air into supplemented by the exhaust hood, so that the smoke pipe gas flow kinetic energy increases, exhaust more smoothly reasonable, the real heat loss without affecting the premise of rational water vapor discharge, excess water vapor in the furnace if it can not reasonably discharge but will reduce the oven temperature to produce steam emission beneficial during baking products, avoid dripping water vapor to the product, the impact of product shelf life.

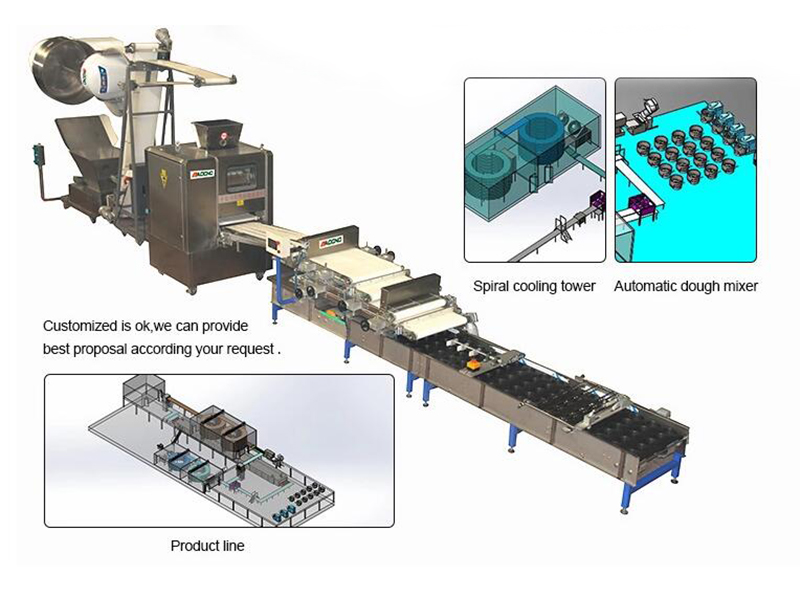

AOCNO Bakery Equipment builds and renovates a variety of fully and semi-automated bakery equipment. We specalize in Spiral cooling tower,Tunnel oven,Mixer,Dough divider.

在线联系供应商

Other supplier products

| High Speed Dough Divider | High Speed Dough Divider Suitable for high-capacity burger hot dogs and other food factories Feature: Automatic dough divider and rounder for produ... | |

| Bread cooler | Bread cooler Temperature: room temperature Why cool bread? During the cooling process of the bread, the temperature gradually decreases, the outer... | |

| hamburger/Bun/Cake/Hot dog production line | hamburger/Bun/Cake/Hot dog production line Available 24,000 pcs/h. Energy: gas or electric Information: Thisbread production lineis one of our popu... | |

| Spiral Fermenting Room | Spiral Fermenting Room Specification: Humidity Control 60%-90% Proofing time adjustable(min) 30min-120min Belt width range(mm) 23... | |

| Rotary oven | Rotaryoven Introduction:Ourrotary ovenboast assure large baking area with minimum surface requirement. And also with a steam system which provides ... |

Same products

| VISUAL EFFECTS DESIGN | 卖方: LUOYANG FIREFISHS CULTURE COMMUNICATION CO.,LTD. | the volume visual effects Service is dedicated to crafting astonishing and lifelike visual effect... | |

| VIDEO PACKAGING1 | 卖方: LUOYANG FIREFISHS CULTURE COMMUNICATION CO.,LTD. | Our Video Packaging Service offers businesses tailored and efficient packaging solutions. With ou... | |

| SOCIAL MEDIA VIDEOS MAKING | 卖方: LUOYANG FIREFISHS CULTURE COMMUNICATION CO.,LTD. | Our Social Media Videos Making Service provides a professional solution for crafting captivating ... | |

| FireFishs - Motion Graphics | 卖方: LUOYANG FIREFISHS CULTURE COMMUNICATION CO.,LTD. | Our good motion graphics services cater to a variety of needs. Whether it's Video Packaging, Spor... | |

| FireFishs - Motion Design | 卖方: LUOYANG FIREFISHS CULTURE COMMUNICATION CO.,LTD. | css motion design encompasses a wide range of services designed to captivate audiences and convey... |