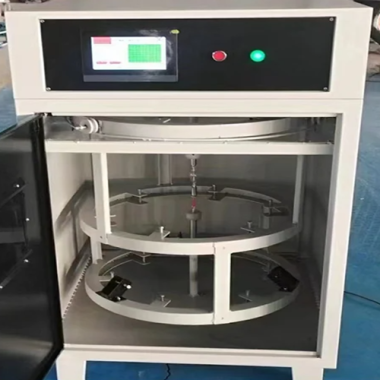

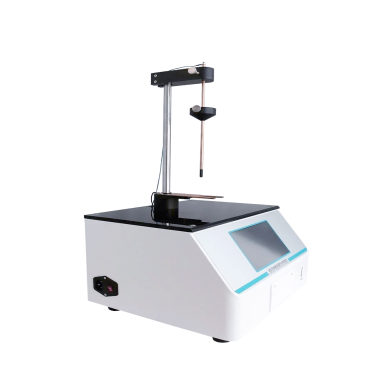

Cork Puncture and Chip Detection Instrument

The rubber stopper puncture debris detector is a device specifically used to detect the number of debris generated during the puncture process and the puncture force of rubber stoppers (especially those for injectables). The following is a detailed description of its main uses, compliance standards, and technical parameters:

Standards

- YBB00332004 - 2015 Determination of Puncture Debris of Rubber Stoppers and Gaskets for Injectables - YBB00322004 - 2015 Determination of Puncture Force of Rubber Stoppers and Gaskets for Injectables - GB 8368 - 2018 (May involve relevant standards for packaging materials, but the specific details need to be determined according to the equipment's intended use and the information provided by the manufacturer) These standards specify in detail the test methods for the puncture debris and puncture force of rubber stoppers, specimen preparation, test conditions, etc., providing a unified standard for the use of the detector.

Main Uses

The main purpose of the rubber stopper puncture debris detector is to evaluate the puncture debris - generating performance and puncture force of rubber stoppers to ensure they meet relevant standards and requirements. Through testing, rubber stoppers with puncture debris issues can be promptly identified and removed, preventing unqualified products from entering the market, thus safeguarding the safety and effectiveness of drugs. This device is widely used in the medical, pharmaceutical, and packaging industries, and is of great significance for ensuring drug quality and patient safety.

Technical Parameters

- Puncture Force Range: Generally, it can reach 0 - 200N, and the specific value varies depending on the equipment model and brand. This range covers the testing needs for most rubber stopper puncture tests.

- Control System: PLC control systems are mostly adopted to achieve precise control and data recording. The PLC system is characterized by high stability and reliability, ensuring the accuracy and traceability of the testing process.

- Operation Interface: Equipped with a 7 - inch touch - screen operation interface, which supports Chinese - English switching for simple and intuitive operation. The touch - screen interface allows operators to easily set testing parameters, monitor the testing process, and view test results.

- External Dimensions: Approximately 500mm×500mm×450mm (The specific dimensions may vary depending on the equipment model and brand), making it easy to place and move. The compact design enables the equipment to be used in different production sites and laboratories.

- Puncture Speed: It can be set arbitrarily within the range of 0 - 100mm/min, and the design value range can reach 0 - 200mm/min. Different puncture speeds can simulate different puncture conditions, allowing for a more comprehensive evaluation of the puncture performance of rubber stoppers.

- Test Materials: Applicable to the puncture debris performance testing of rubber stoppers for various specifications of vials, ampoules, cartridge vials, infusion bottles, etc. Meanwhile, the equipment also has the ability to customize test fixtures for different samples to adapt to various specifications of specimens.

- Data Recording and Processing: The equipment can automatically record test data and generate test reports, facilitating subsequent quality traceability and analysis. Some equipment also supports remote data uploading and cloud storage functions, making the management of test data more convenient and efficient.

在线联系供应商

Other supplier products

| Nasal Oxygen Cannula Tester YY/T 1543 | Introduction The Nasal Oxygen Tube Tester plays a crucial role in the medical field. The following is a detailed introduction to its main uses, co... | |

| Catheter Residual Vacuum Tester YY/T 0339 | Compliance Standards YY/T 0339 - 2019 Suction Catheters for the Respiratory Tract, etc. Main Uses The catheter residual vacuum tester is mainly ... | |

| Constant elongation stress meter | Tensile Testing Machines | Standard constant tensile stress meter conforms to the standard GB/T 21461.2-2008 Plastic ultra-high molecular weight polyethylene (PE-UHMW) moldi... | |

| Helmet UV Pretreatment Box Tester / Helmet UV pretreatment box | Product Introduction Helmet ultraviolet pretreatment box is used for helmet ultraviolet irradiation pretreatment, according to the new national st... | |

| Geomembrane Environmental Stress Cracking Resistance Tester | Scope of application: The stress cracking strength of polyolefin geomembrane was measured and evaluated by notch constant load tensile test. Durin... |

Same products

| Bottle Wall and Bottom Thickness Tester | 卖方: Standard Group (Hong Kong) Limited | The wall and bottom thickness tester for bottles is a measuring instrument widely used in the pha... | |

| Pinhole Tester / Pinhole Testing Equipment | 卖方: Standard Group (Hong Kong) Limited | The pinhole tester for aluminum foil is a device specifically used to detect micro - pinholes in ... | |

| Cork Puncture and Chip Detection Instrument | 卖方: Standard Group (Hong Kong) Limited | The rubber stopper puncture debris detector is a device specifically used to detect the number of... | |

| Aluminum Ointment Tube Toughness Tester | 卖方: Standard Group (Hong Kong) Limited | The ductility tester for aluminum tubes is a device specifically used to detect the ductility ind... | |

| Vacuum leak tester / Vacuum leak instrument | 卖方: Standard Group (Hong Kong) Limited | Vacuum Decay Leak Tester specializes in the detection of leaks in ampoules, vials, injection bott... |