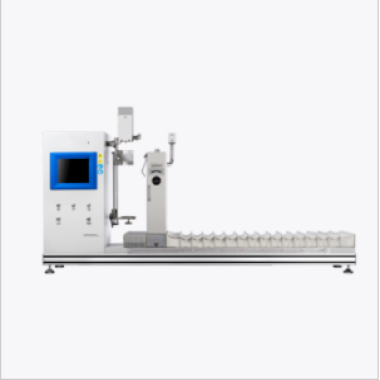

Torsional Fatigue Tester

Standard

YY/T 0857-2011 (China): Specifies torsional fatigue testing protocols for spinal pedicle screw-rod systems, including load ratios, frequency, and failure criteria.

YY/T 1560-2017 (China): Defines methodologies for evaluating the fatigue strength of spinal implant assemblies under complex loading.

ASTM F1717-18 (International): Standard test methods for spinal implant constructs in vertebrectomy models.

ASTM F2706-19: Specifies static and fatigue testing requirements for occipito-cervical and occipito-cervico-thoracic spinal implants.

Product Advantages

Multi-Axis Torsion Control: Advanced electromagnetic actuators maintain R=-1 load ratio (fully reversed torsion) with ±0.05% accuracy.

5 Million Cycle Endurance: Proven capability to complete YY/T 0857’s 5×10⁶-cycle fatigue test without calibration drift.

Dynamic Angle Control: 0.001° resolution ensures precise replication of physiological spinal motion.

Real-Time Fracture Detection: AI-powered acoustic emission monitoring identifies micro-cracks at sub-millisecond intervals.

Intuitive Workflow: 21.5” capacitive touchscreen with gesture control and pre-loaded SOPs for 10+ implant geometries.

Modular Environmental Chambers: Quick-swap pods for simulated physiological (-20°C to +50°C) and corrosive environment testing.

Product Features

Electromagnetic Servo Motors: Dual-axis torsional actuators (±180° rotation, 50 Nm peak torque).

6-DOF Kinematic Simulation: Replicates natural spinal motion (flexion/extension ±20°, lateral bending ±15°, axial rotation ±10°).

Dynamic Load Control: 0.1–5 Hz frequency range with programmable waveforms (sine, square, random, custom).

Thermal-Mechanical Chamber: ±0.3°C temperature stability with integrated humidity control (10–95% RH).

High-Speed Imaging Ready: Syncs with external cameras for full-field strain mapping (DIC optional upgrade).

Safety System: Triple-redundant emergency stop, overload clutches, and laser-based specimen breakage detection.

Technical Parameters

| Parameter | Specification |

|---|---|

| Max. Torsional Moment | ±50 Nm (1 Nm resolution) |

| Angular Range | ±180° (0.001° resolution) |

| Frequency Range | 0.1–5 Hz (0.01 Hz increments) |

| Load Ratio (R) | -1 to 0.1 (adjustable) |

| Temperature Control | -20°C to +50°C (PT1000 sensors) |

| Humidity Control | 10–95% RH (non-condensing) |

| Data Sampling Rate | 100 kHz (synchronized across 16 channels) |

| Power Requirements | 220V/110V ±10%, 50/60Hz, 2.500W |

| Dimensions (W×D×H) | 1.800 × 1.200 × 2.100 mm |

| Weight | 1.100 kg (including environmental chamber) |

| Noise Level | <65 dB (A-weighted) |

Accessories

Spinal Implant Fixture Kit:

Self-centering pedicle screw clamps (4.5–7.5 mm diameter compatibility)

Rod-bending jigs with laser-aligned loading anvils

Thermal-Mechanical Chamber:

20L capacity with rapid cooling/heating (15°C/min)

316L stainless steel interior with HEPA filtration

TorsionMaster Pro Software:

Automated S-N curve generation and fatigue limit calculation

21 CFR Part 11-compliant audit trail with blockchain timestamping

Remote monitoring via dedicated iOS/Android app

Operator Kit:

Calibrated torque wrench set (0.5–50 Nm)

Specimen alignment gauges (ASTM F1717 compliant)

Calibration Bundle:

NIST-traceable torque calibration weights

Angular encoder verification tool

Safety Kit:

Laser safety curtains

Acoustic enclosure with 30 dB noise reduction

在线联系供应商

Other supplier products

| Ignition Distance Measurer for Spray Aerosols | Product Description Conforms to UN Recommendations on the Transportation of Dangerous Goods - Manual of Tests and Criteria 31.4 Ignition Distance ... | |

| Constant Temperature Chamber | Features and Benefits 1.Using advanced temperature control system and high-precision temperature sensor, the temperature can be accurately control... | |

| Sliding Bearing Fatigue Test device | Standards ASTM D2596 / ASTM D2783 / IP 239 EP, DIN 51350 / 1-5. ISO / CD 11008. VW 1444. VW 1454 Material Research and Development During the re... | |

| Helmet Strap Tensile Strength Measuring Instrument | Purpose Apply a certain initial load to the helmet strap system for a certain period of time. Then, let a weight of a certain mass fall from a cer... | |

| Safety Helmet Impact Acceleration Tester | The safety helmet impact acceleration tester is an instrument used to test the performance of safety helmets when subjected to impact. It can simul... |

Same products

| Xenon Test Chamber | 卖方: Standard International Group (HK) Limited | Features and Benefits 1.The use of xenon arc lamp as a light source, can simulate the full sunli... | |

| Single Cable Vertical Flame Tester | 卖方: 上海千实精密仪器 | Introduction Single Cable Vertical Flame Tester is used for the vertical flame propagation of a ... | |

| Safety Helmet Flammability Tester | 卖方: 上海千实精密仪器 | Product Introduction: Safety hat flame retardant performance tester for safety hat flame retarda... | |

| Furniture flammability tester | 卖方: 上海千实精密仪器 | Product details Furniture flammability tester is mainly used to test the combustion performance ... | |

| Flame retardant testing machine | 卖方: 上海千实精密仪器 | Feature highlights: Flame Retardant Tester is designed for testing plastic runway surface layers... |