Dry and Wet Retroreflectometer

Standards

EN ISO 20471:2013

ANSI/ISEA 107-2015

GB 20653-2006

GB/T 18833

Main uses

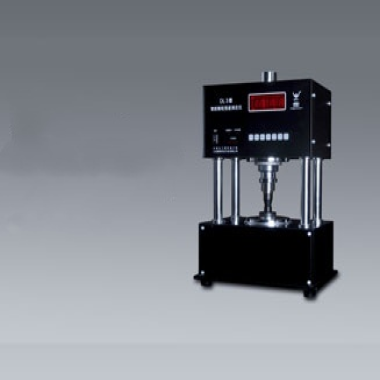

Dry and wet sand abrasive wear testing machine is mainly used to evaluate the wear resistance of materials in dry and wet sand abrasive environment. By simulating the wear environment of dry sand or wet sand in actual working conditions, the testing machine can quantitatively test the wear resistance of different materials. This kind of equipment has a wide range of application value in material research and development, product quality control, industrial production and other fields.

Specifically, the main uses of dry and wet sand abrasive wear testing machines include:

Material research and development; In the development process of new materials, wear-resistant parts are an important performance index. Dry and wet abrasive wear testing machines can help developers quickly and accurately evaluate the wear resistance of new materials, thereby guiding the optimal design of materials.

Industrial production: In industrial production, many parts need to have good wear resistance to ensure product stability and service life. By using dry and wet sand abrasive wear testing machines to test parts, it can help enterprises screen out materials and processes with good wear resistance, thereby improving product quality.

Quality control: Dry and wet abrasive wear testing machines are also widely used in product quality control. Through the wear resistance test of the products produced, the unqualified products can be found and treated in time to ensure that the products flowing to the market have good resistance.

Support Services

1 English Manual

2 Certificate of Quality

3 Remote Online Support

4 Breakdown Support

5 Applications Support

6 12 months warranty

7 CE, ISO 17025 Certificate

8 7 * 24 Service

9 Spare Parts

10 Training

11 Installation

Applicable standards

Dry and wet abrasive wear testing machines usually need to follow certain standards and specifications when testing. Here are some common applicable standards:

ASTM Standards: Standards developed by the American Society for Materials and Testing (ASTM) include content related to dry and wet abrasive wear testing. For example, the ASTM G65 standard may specify specific methods and requirements for abrasive wear tests of dry-sand rubber wheels; The ASTM G105 standard may specify specific requirements for abrasion test methods for wet sand rubber and rubber wheels. These standards specify parameters and requirements such as loading methods, abrasive types, test cycles, and data recording during the test process.

B Ash standard: China's machinery industry standard (B Ash) may also contain content related to dry and wet abrasive wear tests. For example, the JB/ 7705 standard specifies the rubber wheel method in the wear test method for loose abrasive particles, which can be used to evaluate the wear resistance of materials in dry sand environments. In addition, JB/T 9396 and other standards may specify the size of the sample, fixture design and other specific requirements.

When conducting dry and wet sand abrasive wear tests, it should be ensured that the selected standards are consistent with the test purposes and requirements, and the test methods and steps specified in the standards are strictly operated. At the same time, it is also necessary to pay attention to the calibration and maintenance of the testing machine to ensure the accuracy and reliability of the test results.

Specifications

Light resource:Standard Light A, color temperature 2856K

Illuminometer: 0.01lux~200klux (Equipped with machine)Optical

detectorAngular aperture: δく12′

observation angle a:12′ ~2° adjustable,accuracy:6′

angle of incidence β:0° ~40° adjustable,accuracy:1°

Sample holder:Available to accurate locate between first spindle β 1 and

Sample holder second spindle β2

Thedistancefromopticaldetector to specimen surface:15m (need 15 darkroom); Configure thelaser rangefinder

Nozzle diameter:1.19mm, to produce a conical and steadywater column for water pipe

Nozzle distance to specimen:1000mm

Sample holder device:Specimen size: 150*150mmor 50*50mm

Spray water speed:284mm/h

Time control:0-99.99min, accuracy:0.01min

在线联系供应商

Other supplier products

| Particle Strength Tester | Standard ASTM D4179: Standard Test Method for Single-Pellet Pressure Resistance of Catalysts and Catalyst Carriers ASTM D6175: Standard Test Me... | |

| Spinal Internal Fixation Components System Tester | Standard YY/T 0961-2014 (China): Specifies static/fatigue testing protocols for spinal fixation systems, including connection integrity and anti-l... | |

| Cut Susceptibility Tester | Standard IEC 61730-2: Photovoltaic (PV) Module Safety Qualification – Requirements for Testing UL 1703: Flat-Plate Photovoltaic Modules and... | |

| Taber abrasion tester | Standards: ASTM D3884 、 ASTM D1175 、 ASTM D1044 、 ASTM D4060 、 TAPPI T476 、 ISO 9352 、 ISO 5470-1 、 JIS K7204 、 JIS A1453、 JIS K6902 、 JIS L1096 、... | |

| Temperature and Low Air Pressure Test Chamber | Features and Benefits 1.The test chamber combines a wide temperature and humidity range, low pressure range, can complete a variety of complex low... |

Same products

| Xenon Test Chamber | 卖方: Standard International Group (HK) Limited | Features and Benefits 1.The use of xenon arc lamp as a light source, can simulate the full sunli... | |

| Single Cable Vertical Flame Tester | 卖方: 上海千实精密仪器 | Introduction Single Cable Vertical Flame Tester is used for the vertical flame propagation of a ... | |

| Safety Helmet Flammability Tester | 卖方: 上海千实精密仪器 | Product Introduction: Safety hat flame retardant performance tester for safety hat flame retarda... | |

| Furniture flammability tester | 卖方: 上海千实精密仪器 | Product details Furniture flammability tester is mainly used to test the combustion performance ... | |

| Flame retardant testing machine | 卖方: 上海千实精密仪器 | Feature highlights: Flame Retardant Tester is designed for testing plastic runway surface layers... |