S5 Cold Work Tool Steel Plates Bars Sheet Forgings

Preheating: Heat at a rate not exceeding 400°F per hour (222°C per hour). For complex and large tools, heat to 1150-1250°F (621-677°C) and equalize. Then heat to 1300-1400°F (704-760°C) and equalize. For simple geometries, use only the second preheating temperature range.

S5 Shock-Resisting Tool Steel is a silicon-manganese tool steel which exhibits the highest impact toughness among all of the "S" type steels. The high toughness and the ability to be hardened to 62 Rockwell C make S5 an excellent choice for applications that require higher strength than S7 shock-resisting tool steel. The steel is typically hardened using an oil quench, but for simple geometries, the steel may be water quenched.

APPLICATIONS: Pneumatic tools, shear blades, mandrels, heavy-duty punches, and stamping dies.

COMPOSITION

|

C |

Mn |

Si |

Cr |

Mo |

V |

PHYSICAL PROPERTIES

Density: 0.280 lb/in3(7750 kg/m3)

Specific Gravity: 7.75

Modulus of Elasticity: 30 x 106 psi (207GPa)

Machinability: 65-70% of a 1% carbon steel

HARDENING

Critical Temperature:Ac1: 1410°F (766°C)

Preheating: Heat at a rate not exceeding 400°F per hour (222°C per hour). For complex and large tools, heat to 1150-1250°F (621-677°C) and equalize. Then heat to 1300-1400°F (704-760°C) and equalize. For simple geometries, use only the second preheating temperature range.

Austenitizing (High Heat): Heat slowly from the preheat. For Oil Quenching: 1600 - 1700°F (871 - 927°C) For Water Quenching: 1550 - 1650°F (842 - 899°C) Soak for 30 minutes for the first inch (25.4 mm) of thickness, plus 15 minutes for each additional inch (25.4 mm) of thickness.

Quenching: Oil or water to 150-125°F (66-51°C).

Tempering: Temper immediately after quenching. Hold at temperature for 1 hour per inch (25.4 mm) of thickness, 2 hours minimum, then air cool to ambient temperature. To minimize internal stresses in cross sections greater than 6 inches (152.4 mm) and to improve stability in tools that will be EDM’d after heat treatment, a soaking time of 4 to 6 hours at the tempering temperature is strongly recommended.

Cryogenic Treatment: Some prefer to do cryogenic treatment as an extension of the quench from the austenitizing treatment. Others prefer to cryogenically treat after tempering.

:Hubei Risunsteel Co., Ltd.

ANNEALING

Annealing must be performed after hot working and before re-hardening.

Heat at a rate not exceeding 400°F per hour (222°C per hour) to 1425 - 1475°F (773 - 801°C), and hold at temperature for 1 hour per inch (25.4mm) of maximum thickness; 2 hours minimum. Then cool slowly with the furnace at a rate not exceeding 50°F per hour (28°C per hour) to 1000°F (538°C). Continue cooling to ambient temperature in the furnace or in air. The resultant hardness should be a maximum of 229 HBW.More information .

,based on the over one hundred years’s production history of in Huangshi, provide professional services and material for cutting tool companies, mould companies and other industrial enterprises all over the world for years.

在线联系供应商

Other supplier products

| D3/1.2080 Cold Work Tool Steel Plates Bars Sheet Forgings | Commonly used for manufacturing cold work moulds of excellent abrasion resistance with light shock loads, punch heads, cold cutting scissors, dril... | |

| High toughness H13 1.2344 SKD61 Hot Work Tool Steel | Product Details Chemical Composition (%) Standard Steel Grade C Si Mn P S Cr Mo V W DIN - ASTM H13 ... | |

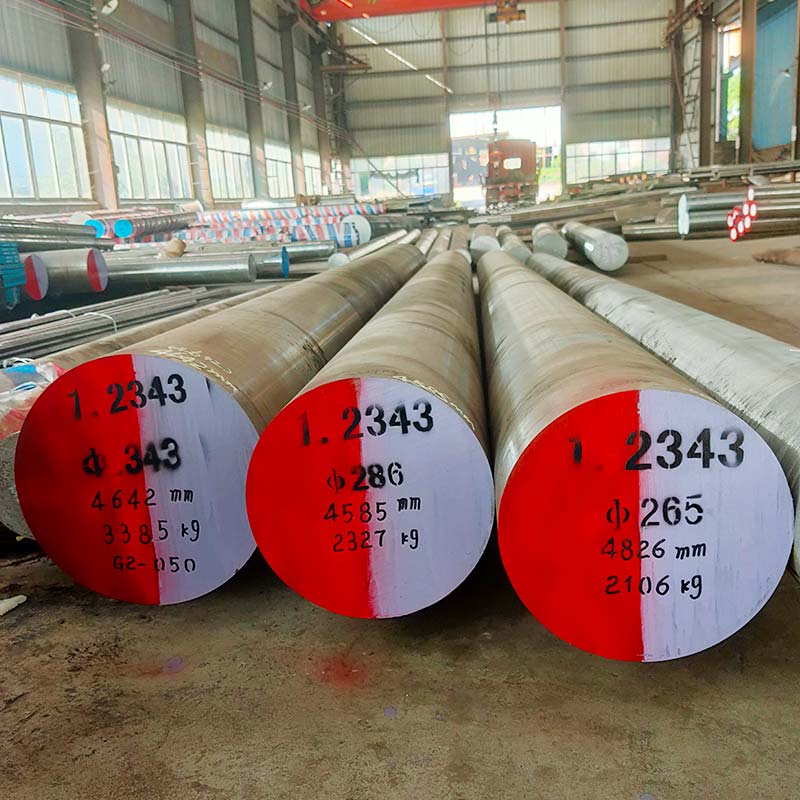

| H11/1.2343 Hot Work Tool Steel Following NADCA standard | Product Details Chemical Composition (%) Standard Steel Grade C Si Mn P S Cr Mo V W DIN - ASTM H11 ... | |

| 45CrNi4Mo/1.2767 Hot Work Tool Steel Plates Bars Sheet Forgings | Product Details Chemical composition C Mn Si Cr V Mo P S - ≤0.03 ≤0.03 Equivalent grades: DIN AFNO... | |

| S5 Cold Work Tool Steel Plates Bars Sheet Forgings | Preheating: Heat at a rate not exceeding 400°F per hour (222°C per hour). For complex and large tools, heat to 1150-1250°F (621-677&de... |

Same products

| Centrifugally cast Chromium-Nickel alloy tubes | 卖方: Nanjing Xinshuo Mechanical Equipment Co., Ltd. | Centrifugally cast Chromium-Nickel straight alloy tubes | |

| White Iron Wear Blocks, Wear Bars | 卖方: Yiwu WALKSON Machinery Equipment Co., Ltd. | The unique, formable designed wear bars is available in various lengths, grades and sizes and can... | |

| TITANIUM ALLOY STEEL TUBE | 卖方: YUHONG GROUP CO., LIMITED ZHEJIANG YUHONGWELL STEEL CO., LIMITED | TITANIUM ALLOY STEEL TUBE Titanium is the ninth most abundant element in the earth's crust and t... | |

| STEEL FITTING | 卖方: YUHONG GROUP CO., LIMITED ZHEJIANG YUHONGWELL STEEL CO., LIMITED | STEEL FITTING Steel has been used for making pipe and pipe fittings for years for its durability... | |

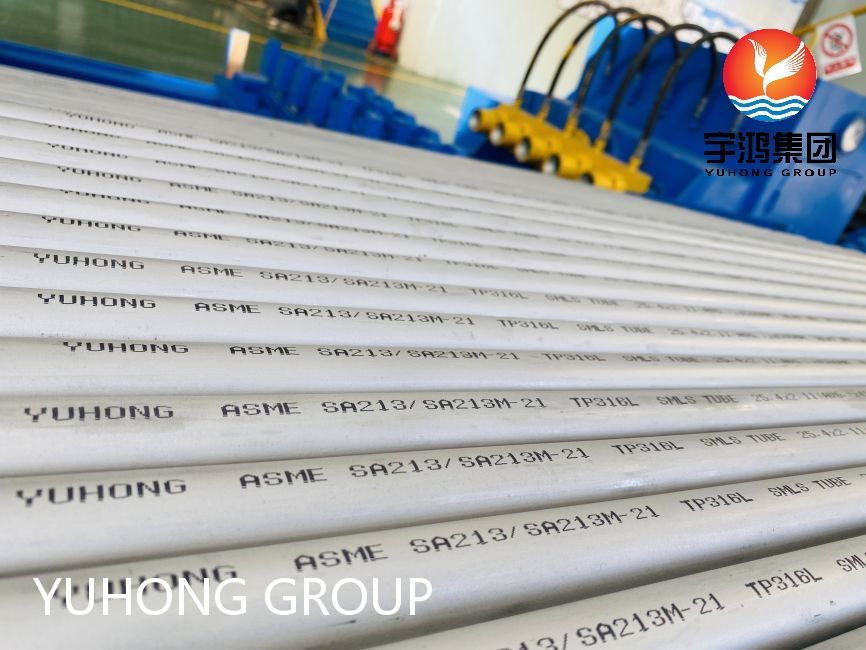

| STAINLESS STEEL PIPE/TUBE | 卖方: YUHONG GROUP CO., LIMITED ZHEJIANG YUHONGWELL STEEL CO., LIMITED | STAINLESS STEEL PIPE/TUBE Stainless steel pipe/tube is one of the most widely used in manufactur... |