PA6 Compound Manufacturer

As a, share with you the factors that affect the toughening effect of modified plastics.

The three major factors that affect the toughening effect of modified plastics are explained in detail: the characteristics of the matrix resin, the characteristics and amount of the toughener, and the binding force between the two phases, which are described in detail below:

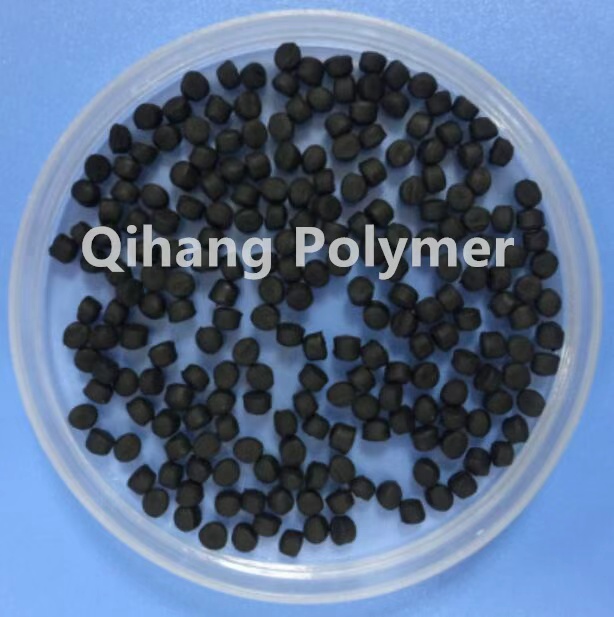

Toughening Nylon PA6 Granules

First, the characteristics of the matrix resin

Increasing the toughness of the matrix resin is conducive to improving the toughening effect of toughened plastics. Improving the toughness of the matrix resin can be achieved in the following ways:

Increase the molecular weight of the matrix resin to narrow the molecular weight distribution; improve toughness by controlling whether it is crystalline and the degree of crystallinity, crystal size, and crystal form. For example, adding a nucleating agent to theincreases the crystallization rate and refines the grains, thereby improving fracture toughness.

Second, the characteristics and amount of toughener

1. Effect of particle size of the dispersed phase of the toughening agent-For elastomer toughened plastics, the characteristics of the matrix resin are different, and the optimal value of the particle size of the dispersed phase of the elastomer is also different. For example, the optimal particle size of rubber in HIPS is 0.8-1.3 μm, the optimal particle size of ABS is about 0.3 μm, and the optimal particle size of PVC-modified ABS is about 0.1 μm.

2. The effect of the amount of toughening agent, there is an optimal value for the amount of toughening agent, which is related to the particle spacing parameter.

3. The effect of toughening agent glass transition temperature. Generally, the lower the glass transition temperature of the elastomer, the better the toughening effect.

4. The influence of the interface strength between the toughener and the matrix resin, and the influence of the interface bond strength on the toughening effect varies from system to system.

5. The effect of the elastomer toughener structure is related to the type of elastomer and the degree of crosslinking.

Third, the binding force between the two phases

The two phases have a good bonding force, which can effectively transfer between the phases when stress occurs and consume more energy. On the macro level, the better the overall performance of plastics, especially the improvement in impact strength. Generally, this binding force can be understood as the interaction force between the two phases. Graft copolymerization and block copolymerization are typical methods to increase the two-phase binding force. The difference is that they form chemical bonds through chemical syntheses, such as bonding. Branch copolymer HIPS, ABS, block copolymer SBS, polyurethane.

Our company also hason sale, welcome to consult.

在线联系供应商

Other supplier products

| Flame Retardant PC Granules | Injection molding, Flame Retardant up to UL94-V0 (3.0MM), high toughness, high impact strength, high temperature resistance, high gloss and stron... | |

| Glass Fiber Reinforced Nylon PA6 Granules | Glass Fiber Reinforced Nylon PA6 Granules Injection grade, glass fiber reinforced nylon PA6 material, high impact resistant, high strength resistan... | |

| PP modified material | Injection grade, 5%~40% talc/mineral filled PP material, high strength, smooth surface customized Main Applications: small appliance housings, air... | |

| Anti-cold Nylon PA6 Granules | Anti-cold Nylon PA6 Granules Injection Molding Grade, Anti-cold -40°C, Toughening. Main Applications: Automotive parts, Electronic Appliances... | |

| Flame Retardant ABS Material | is the world's largest general-purpose engineering plastic. It is a light yellow granular or beaded resin. It is non-toxic, odorless, and has low w... |

Same products

| Thermoplastic vulcanized rubber | 卖方: Jiangsu Qihang Polymer Technology Co.,Ltd. | We hold ISO9001, ROHSand REACH certifications, ensuring global compliance. Excellent weather res... | |

| thermoplastic elastomer tpe material 45A-50D | 卖方: Jiangsu Qihang Polymer Technology Co.,Ltd. | ||

| polyurethane thermoplastic elastomers based on carbamate copolymers (TPU) | 卖方: 854417 | Chemprene® 600系列是一类以氨基甲酸酯共聚物为基材的聚氨酯热塑性弹性体(TPU)。产品分为聚醚和聚酯两种类型,可广泛应用于汽车配件、电子组件、运动配件、密封件、鞋饰片、材料复... | |

| thermoplastic dynamic vulcanized rubber (TPV) | 卖方: 854417 | Chemprene® 900系列是EPDM/PP为基材的热塑性动态硫化橡胶(TPV),可根据不同客户的需求进行定制化服务,给客户产品的应用场景提供出最理想的解决方案 | |

| thermoplastic elastomer TPE | 卖方: 854417 | Chemprene® 800系列是SEBS/PP为基材的热塑性弹性体(TPE),可根据不同客户的需求进行定制化服务,给客户产品的应用场景提供出最理想的解决方案。 |