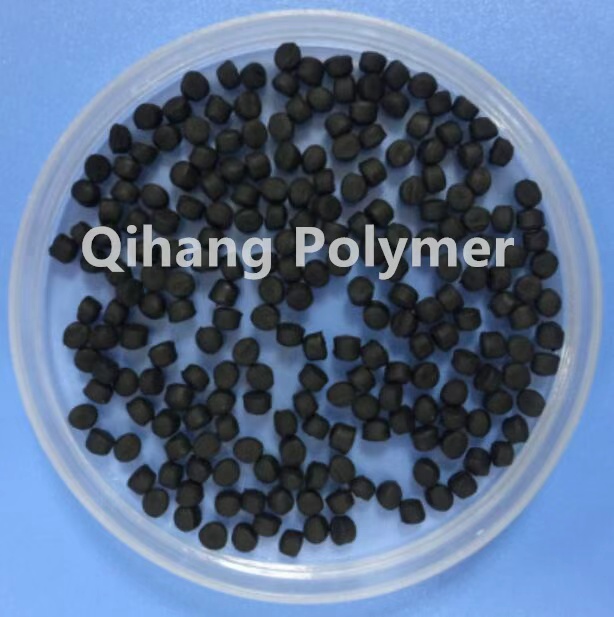

Flame Retardant ABS Material

is the world's largest general-purpose engineering plastic. It is a light yellow granular or beaded resin. It is non-toxic, odorless, and has low water absorption. It has good comprehensive physical and mechanical properties, such as excellent electrical properties, abrasion resistance, and stable size. Properties, chemical resistance, surface gloss, etc., and easy to process. The disadvantages are weather resistance, poor heat resistance, and flammability.

There are three main ways to reduce the flammability of ABS resin:

1. Blend with flame retardant polymer and ABS, such as CPE, PVC;

2. Chemical modification of existing ABS, such as adding tribromostyrene as the fourth monomer to prepare four-component ABS;

3. Add flame retardants to ABS through common methods, including inorganic flame retardants (such as MoO3) and organic flame retardants. The flame retardant type has a highly effective flame retardant effect, but other properties may not be good. Chemically modified ABS requires a specific production process, the process is more complicated, the third method strikes a balance between cost and performance, and is more flexible in designing multifunctional materials.

As an, share with you the knowledge of flame retardants. A flame retardant is an additive added to plastics to increase the difficulty of burning plastics.

1. Purpose of adding flame retardant

Resin is a high molecular organic compound, so it is flammable. With the increase of plastic products in our living environment, fires caused by plastic are common and have become one of the key concerns of the club. The combustion of plastic is a very complicated and intense oxidation reaction. The combustion process is continuously heated by external heat sources. The plastic first undergoes a free-radical chain degradation reaction with oxygen in the air to produce volatile combustibles. When a certain temperature and temperature are reached, It will burn when the concentration, and the heat released by the combustion will aggravate the plastic degradation of Taurus, generating more flammable gases to make the combustion more intense. The addition of flame retardants makes this combustion process difficult or slow.

2. Mechanism of flame retardant

(1) Separate oxygen from combustible materials. Oxygen is a major factor in combustion. Without oxygen or lack of oxygen, it is difficult to burn.

(2) The active free radicals generated during the combustion of plastics are trapped to generate water or hydrogen, which interrupts the chain oxidation reaction, which is the slowing down of the combustion and thus stops it.

(3) The flame retardant can absorb a large amount of heat during endothermic decomposition and dehydration, thereby suppressing the temperature rise of the burning part and its vicinity, making it difficult to continue the combustion.

Often the effect of one flame retardant is not necessarily ideal. In practice, several flame retardants can be used together, and the effect is much better.

Our company hason sale, welcome to consult.

在线联系供应商

Other supplier products

| PA6 Compound Manufacturer | As a, share with you the factors that affect the toughening effect of modified plastics. The three major factors that affect the toughening effect ... | |

| PP modified material | Injection grade, 5%~40% talc/mineral filled PP material, high strength, smooth surface customized Main Applications: small appliance housings, air... | |

| Glass Fiber Reinforced Nylon PA66 Granules | Glass Fiber Reinforced Nylon PA66 Granules Injection molding grade, glass fiber reinforced nylon PA66 material, high impact resistant, high strengt... | |

| Glass Fiber Reinforced PP Granules | Glass Fiber Reinforced PP Granules Injection grade, 5%~45% glass fiber reinforced PP material, high strength, low warpage, customized Main Applic... | |

| Glass fiber Reinforced ABS Material | Injection molding, dimensionally stable, high temperature resistance, low dimensional shrinkage, easy processing. Main Applications: Automotives... |

Same products

| Thermoplastic vulcanized rubber | 卖方: Jiangsu Qihang Polymer Technology Co.,Ltd. | We hold ISO9001, ROHSand REACH certifications, ensuring global compliance. Excellent weather res... | |

| thermoplastic elastomer tpe material 45A-50D | 卖方: Jiangsu Qihang Polymer Technology Co.,Ltd. | ||

| polyurethane thermoplastic elastomers based on carbamate copolymers (TPU) | 卖方: 854417 | Chemprene® 600系列是一类以氨基甲酸酯共聚物为基材的聚氨酯热塑性弹性体(TPU)。产品分为聚醚和聚酯两种类型,可广泛应用于汽车配件、电子组件、运动配件、密封件、鞋饰片、材料复... | |

| thermoplastic dynamic vulcanized rubber (TPV) | 卖方: 854417 | Chemprene® 900系列是EPDM/PP为基材的热塑性动态硫化橡胶(TPV),可根据不同客户的需求进行定制化服务,给客户产品的应用场景提供出最理想的解决方案 | |

| thermoplastic elastomer TPE | 卖方: 854417 | Chemprene® 800系列是SEBS/PP为基材的热塑性弹性体(TPE),可根据不同客户的需求进行定制化服务,给客户产品的应用场景提供出最理想的解决方案。 |