Lead Free HASL PCB

Product Description

HASL is the predominant surface finish used in the industry. The process consists of immersing circuit boards in a molten pot of a tin/lead alloy and then removing the excess solder by using 'air knives', which blow hot air across the surface of the board.

One of the unintended benefits of the HASL process is that it will expose the to temperatures up to 265°C which will identify any potential decontaminationissues well before any expensive components are attached to the board.

|

Application area: Security |

Product feature: Peelable S/M |

|

Layer: 2 |

Surface treatment: Lead Free HASL |

|

Material: FR4 |

Line width/Line space: 0.325/0.305mm |

|

Thickness: 1.6mm |

Min hole φ: 0.75mm |

Choosing a that works best for you and your process while still keeping the environment safe is has become a much more practical solution.

Send product request

Other supplier products

| ENIG automobile reversing radar PCB | Reliability is a key driver for and transportation industries. has developed materials that engineers need to provide excellent heat resistance i... | |

| ENIG BGA PCB | is a surface mount package for integrated circuits. BGAs can provide more interconnect pins than dual in-line or flat packs, each with solder balls... | |

| Lead Free HASL PCB | Product Description HASL is the predominant surface finish used in the industry. The process consists of immersing circuit boards in a molten po... | |

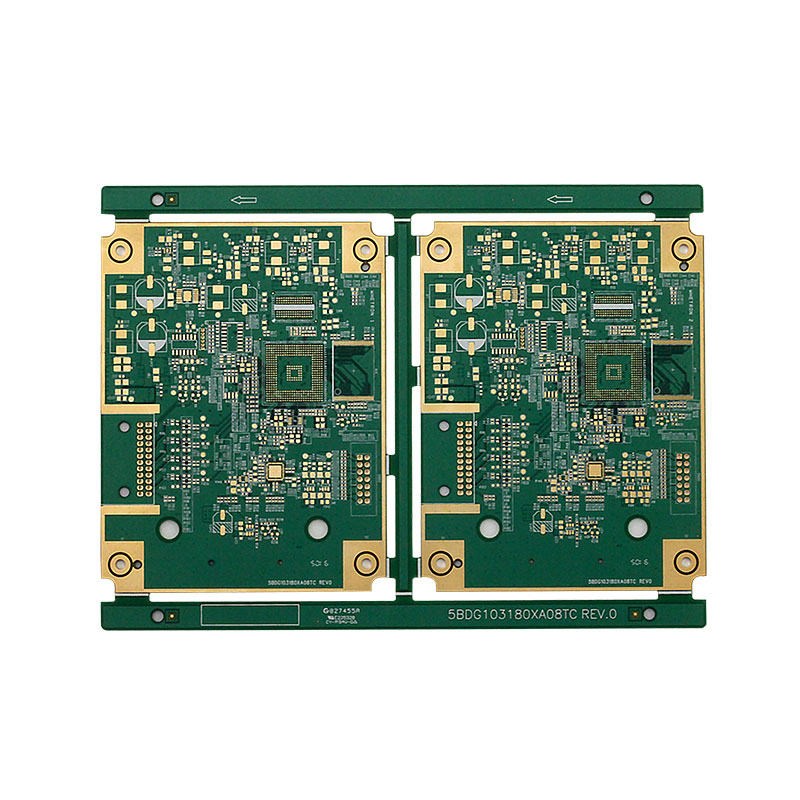

| Motherboard 8 layer motherboard ENIG FR4 PCB | Description Application area: Motherboard Product feature: Eight-layer motherboard Layer: 8 Surface treatment: ENIG ... | |

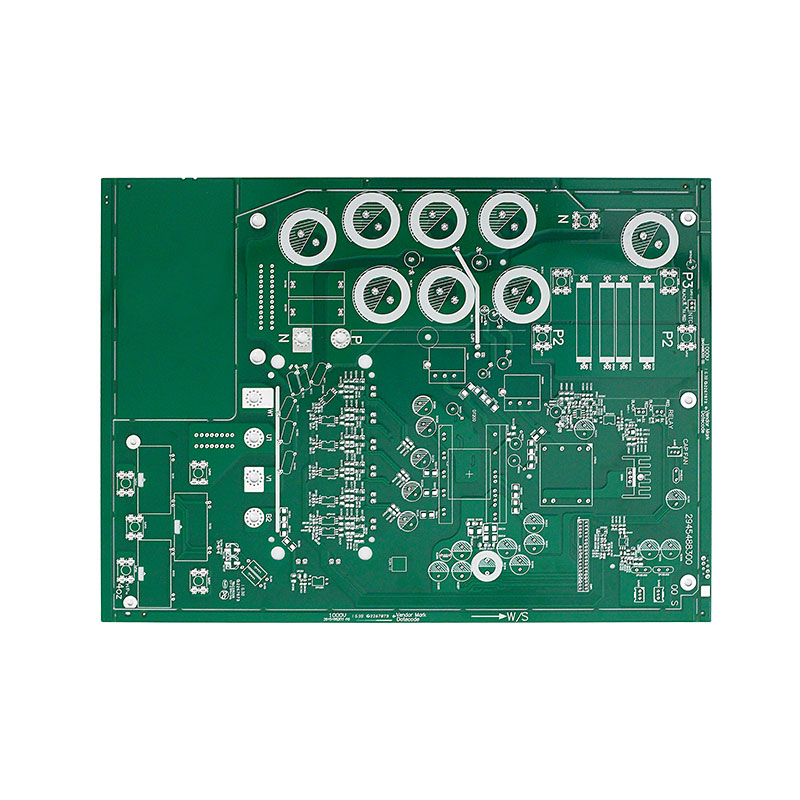

| Lead Free HASL Power heavy duty project | Product Description The outer/inner layer of the has 3 ounces of copper. Because of their thermal management capabilities, these are extremely v... |