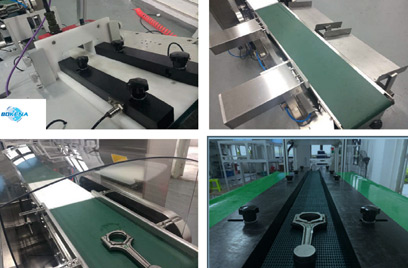

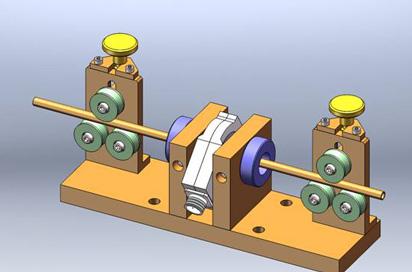

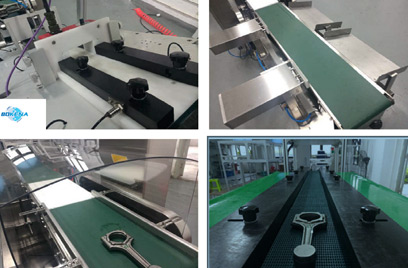

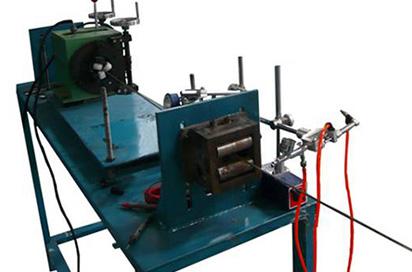

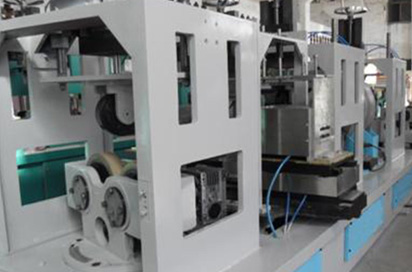

Magnetic Flux Leakage Testing Equipment

Electromagnetic detection is a very important non-destructive testing method and is widely used. Magnetic flux leakage testingis a magnetic method of nondestructive testing that is used to detect corrosion and pitting in steel structures, most commonly pipelines and storage tanks. The basic magnetic flux leakage principleis used to magnetize the steel. When used in combination with other methods, it provides a quick and inexpensive assessment of the workpiece of ferromagnetic materials. With the advancement of technology, people are paying more and more attention to the automation of the inspection process. This not only reduces the labor intensity of the inspection work but also improves the reliability of the test results and reduces the influence of human factors. The MFI magnetic flux leakage inspectionmethod is a highly automated magnetic detection technology. The principle is that after the ferromagnetic material is magnetized, the surface and near-surface defects form a leakage magnetic field on the surface of the material, and defects are detected by detecting the leakage magnetic field. In this sense, the magnetic particle detection technology commonly used in pressure vessel inspection. However, it is customary to use the method of measuring the leakage flux with a sensor as the magnetic flux leakage detection, and the magnetic flux to detect the leakage flux. The method is called magnetic particle detection and they are juxtaposed into two detection methods.

Magnetic flux leakage ndtcan only detect surface and near-surface crack defects, and it needs surface grinding when testing. It is only suitable for the detection of workpiece discontinuation. In addition to the surface and near-surface crack defects, the MFI magnetic flux leakage inspection can also find the corrosion inside the workpiece from the outside. Defects such as pits, and do not need to be polished on the surface of the workpiece, suitable for on-line inspection of workpieces. On-line inspection of workpieces is currently the most urgent method for users, which can reduce unnecessary parking and reduce inspection costs. In addition, the magnetic flux leakage detection can also quantify the depth and length of defects. Although the application of magnetic flux leakage detection technology is rarely used in workpiece inspection, it has the advantages that magnetic particle detection does not have, so its application prospect is very broad.

Nanjing BOKENA Automation System Co., Ltd., originated from the eddy current testing laboratory of the Nanjing University of Technology. It isone of the most professional ndt testing equipment suppliersin China. We sincerely invite and welcome people from all around the world to invest and create more values together.

Send product request

Other supplier products

| LGET-553 Aluminum Tube Eddy Current Flaw Detector | LGET-553 Aluminum Tube Eddy Current Flaw Detector Brief Introduction The aluminum tube is a type of non-ferrous metal which may have one or more... | |

| EDM Notch 1024 | An electric pulse is a pulse generated by electrons, and a pulse is a process of changing a voltage in a short time. Electropulsing is an unsteady ... | |

| GSET-551 Steel Wire Eddy Current Flaw Detector | GSET-551 Steel Wire Eddy Current Flaw Detector Brief Introduction Using the eddy current signal processing method and high-performance DSP alg... | |

| MFL-7389 Tube Magnetic Flux Leakage Detector | Tubing repair is an important measure to reduce the comprehensive cost of production in oil production plants to improve the quality of repairing t... | |

| Valve Tappet Eddy Current Flaw Detector QMTZET-04 | Tappet full automatic eddy current testing system is a full automatic crack hardness sorter that integrates light, electricity and machinery. The w... |

Same products

| Non standard roller bearing for strander machine 527468.ZL | Seller: JinHang Precision Bearing Co.,LTD | Special bearings527468 for tubular stranding machines running at high speeds have increased accur... | |

| Offer Non standard roller bearing for strander machine 535550 | Seller: JinHang Precision Bearing Co.,LTD | The bearing 535550 belongs to large bearings that have threaded holes for the location of eye bol... | |

| Cylindrical roller bearing 527467.ZL Tubular twister machine | Seller: JinHang Precision Bearing Co.,LTD | The dimensional and running tolerances of the bearings with cylindrical bore correspond to tolera... | |

| Cable strander high speed bearing 808288 factory | Seller: JinHang Precision Bearing Co.,LTD | Single row cylindrical roller bearings 808288 with cage are units comprising solid inner and oute... | |

| Precision bearing 535549 for Tubular stranding machine | Seller: JinHang Precision Bearing Co.,LTD | High precision bearings 535549 must guide machine parts with high precision and support forces at... |