Cement Rotary Kiln

Cement Rotary Kiln

Since 1950s, CIC rotary kiln manufacturerhad started manufacturing of pyro processing equipment. These series of pyro processing rotating kiln equipment were used in various fields, that enforce us to overcome many difficulties. Nowadays, our rotary kiln in cement industry meets the incineration requirements of this equipment for various materials. The complete sets of the pyro processing heavy equipment and machinery CIC rotary kilnmanufacturer can provide includes the dry, semi-dry and wet-processed cement rotary lime kiln, self-return soda steam calciner, metallurgy rotary kiln, environmental dryer and cooler, etc which are widely used in the industries of cement producing, metallurgy, chemical, environment protecting and ,etc.

Design of Rotating Kiln

Shell: Kilned carbon steel and alloy steel shell by automatic welding.

Supporting Device: Advanced spindle with automatic temperature measuring device and electronic heater unit.

Tyre and Roller: Made of ZG35CrMo steel and 42CrMo steel.

Driving Device: Rotary lime kiln is equipped with the reducer with the hard tooth surface and flexible diaphragm coupling, by continuous current dynamo or variable-frequency and variable-speed motor.

Kiln Seal Device: Different types of the seal are designed to match the needs.

Low-speed driving device is equipped.

Available for hazardous waste incineration such as chemical waste incinerator and industrial waste incinerator. In addition, fertilizer coolerand fertilizer granulator are also in the custom options.

What are the Design Parameters of Rotating Kiln?

Raw material

Inlet and outlet temperature

Size of rotary kiln

Processing capacity

Scope of supply

How to Stabilize Kiln Temperature in Summer and Keep the Production?

The heat transfer modes of high-temperature gas in a kiln to kiln skin are radiation heat transfer and convection heat transfer;

There is only conduction heat transfer among kiln skin, kiln brick and kiln shell;

There is only convective heat transfer between the outer wall of the kiln and the surrounding environment;

The kiln skin is in close contact with the refractory brick, that is, the temperature of the kiln skin at the contact position is the same as that of the brick;

The firebrick is in close contact with the rotating kiln body, that is, the temperature of the firebrick at the contact part is the same as that of the kiln body;

The inner surface temperature of the cement rotary kilnis the same as the outer surface temperature (the thickness of the kiln is ignored).

Technical Parameters of Rotating Kiln

Technical Parameters of Steam Calcination Kiln for Sodium Bicarbonate with Inner Recycling Of Soda

|

Specification |

Capacity |

Design Pressure(Mpa) |

Design Temperature(℃) |

Work Pressure(Mpa) |

Work Temperature(℃) |

||||

|

m |

t/d |

Tube |

Shell |

Tube |

Shell |

Tube |

Shell |

Tube |

Shell |

|

φ2.5×27 |

400 |

Normal Pressure |

270 |

200 |

Normal Pressure |

238 |

200 |

||

|

φ2.8×27 |

520 |

Normal Pressure |

270 |

200 |

Normal Pressure |

238 |

200 |

||

|

φ3×30 |

660 |

Normal Pressure |

270 |

200 |

Normal Pressure |

238 |

200 |

||

|

φ3.2×32 |

800 |

Normal Pressure |

270 |

200 |

Normal Pressure |

238 |

200 |

||

Send product request

Other supplier products

| Calcium Carbide Furnace Tap Hole Machine | Dig furnace robot arm controlhas a walking mechanism, multi-station operator, hydraulic, electronic control, and other components. The operation is... | |

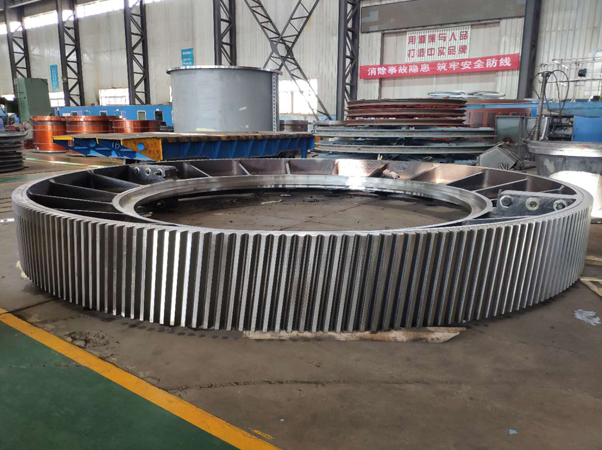

| Girth Gear | CIC is the casting & forging center in central-south China, possessing a 50t electric arc furnace, 60t LF ladle refining furnace, and 60t VD/VO... | |

| Overflow Ball Mill | In recent years, with the continuous development of grinding technology, wet grinding has become the mainstream process, overflow type ball millis ... | |

| Overflow Ball Mill | In recent years, with the continuous development of grinding technology, wet grinding has become the mainstream process, overflow type ball millis ... | |

| Vertical Centrifuge | Vertical Centrifuge The vertical centrifuge machineis made up of the screen which diameter range from 700 to 1,000 mm , the rotor body (including ... |

Same products

| Ordinary Linear Axis (SF) Linear Shaft | Seller: Lishui Jialida Bearing Co., Ltd. | Since the ordinary linear axis and the linear bearing are in point-to-point contact, the surface ... | |

| Accuator shaft 1Cr12 Steam Turbine LP casing for Indonesia Power Plant | Seller: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | Accuator shaft 1Cr12 Steam Turbine LP casing for Indonesia Power Plant is an exclusive product fo... | |

| Cement Rotary Kiln | Seller: CITIC IC LUOYANG HEAVY MACHINERY CO., LTD | Cement Rotary Kiln Since 1950s, CIC rotary kiln manufacturerhad started manufacturing of pyro pr... | |

| Screw Shaft | Seller: NANJING LESUN SCREW CO.,LTD | The extruder shaftspline type is divided into single-key, rectangular spline and involute spline.... | |

| Involute Spline Shaft | Seller: NANJING LESUN SCREW CO.,LTD | The involute shaftis the form of mandrel splines used by all the twin screw extruders over the wo... |