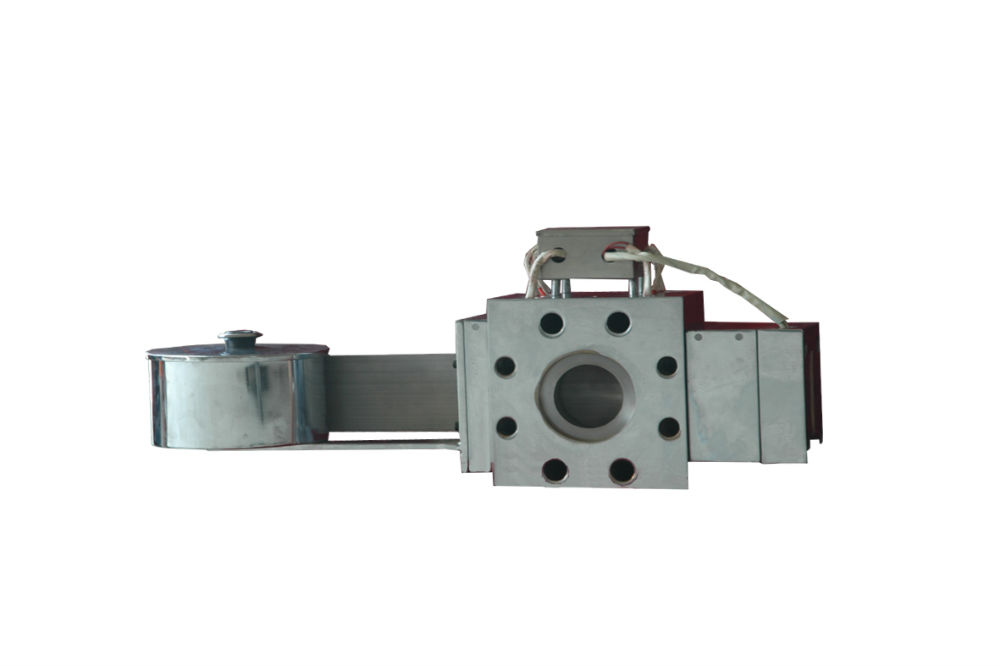

Back flush Screen Changer

Due to the very effective screen cleaning with high pressure impulses, its rate of the screen-cleaning exceeds 80% , repeated usage up to 100-400 times (depending on the filtration fineness), minimizing the screen cost. Eliminate busy operation in the process of filter calcinations, ultrasonic cleaning, chemical immersion, and save the cost of various cleaning equipment.

100% availability of the production line while cleaning and replacing the screen, elimination of scraps. Low operation costs of production.

Filtration area from 365cm2 to 10000cm2. It has been installed on the USA-funded enterprises PS recycling machine, the output is 1100kg / h , filtering accuracy of 40 ~ 60 mesh , the new screen feed pressure 2.5Mpa , after line strength to wash filter , the feed pressure drops ranging from 2.5 ~ 2.7Mpa, screen washed rate is of 90% or more .

It can be used on Fiber, blown film, flat film, cast film , pipe , sheet , wire , recycling and pelletizing.

Other supplier products

All supplier products

Same products

|

|

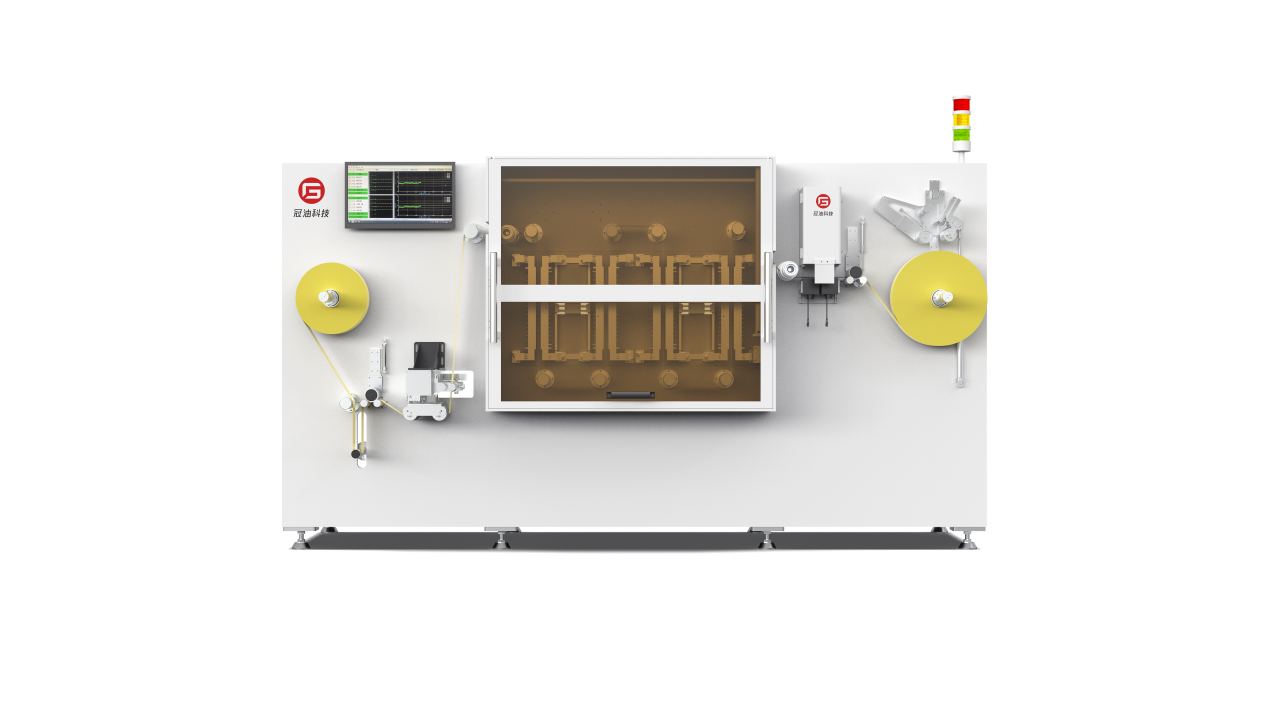

The Single Workstation Electrostatic Perforating Machine |

Seller: Wuhan Guan You Technology Co., Ltd. |

The single workstation electrostatic perforating machineis a professional cigarette paper static ... |

|

|

YZH WHEN1510 Stationary Pedestal Rockbreaker Boom |

Seller: Shandong Yirun Foundation Engineering Co., Ltd |

Below is a detailed introduction to the YZH WHEN1500 fixed hydraulic demolition arm, covering its... |

|

|

YZH WHEN1410 Stationary Pedestal Rockbreaker |

Seller: Shandong Yirun Foundation Engineering Co., Ltd |

YZH WHEN1410 Stationary Pedestal Rockbreaker is a specialized equipment designed for secondary cr... |

|

|

JY-160S2 Standard Plastic Injection Machine |

Seller: Dongguan Jieyang Machinery Co., Ltd |

Straight screw ejected assembly.

Two(three)-phase temperature, ejected speed, backing pressure a... |

|

|

WPC Terrace panel extrusion line |

Seller: Qingdao Trusty Plastic Machinery Co.,Ltd |

Wood-polymer composite (WPC), unlike wood, has higher resistance to aggressive environments and v... |