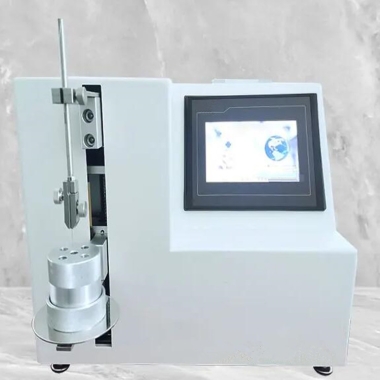

Hot Tack Tester / Heat Seal Tester

Main Uses of the Hot - Tack Tensile Tester

The hot - tack tensile tester is an instrument specifically designed to test the hot - tacking and heat - sealing properties of packaging materials. Its main uses include, but are not limited to: - Evaluating the Heat - Sealing Performance of Packaging Materials: By simulating the heat - sealing conditions of packaging production lines, it tests the strength of materials after heat - sealing, ensuring that packaging materials can maintain their integrity during transportation and storage. - Quality Control: During the production of packaging materials, regular testing with a hot - tack tensile tester can promptly identify production issues, ensuring stable and reliable product quality. - Material R & D: In the process of developing new materials, the hot - tack tensile tester can be used to evaluate the impact of different formulations and processes on the heat - sealing performance of materials, providing a basis for material optimization. - Applications in Multiple Fields: In addition to packaging materials, the hot - tack tensile tester can also be used to test the peeling and breaking properties of soft materials such as adhesives, adhesive tapes, self - adhesive labels, and paper, providing technical support for the application of these materials.

Compliance Standards

GB/T 34445 - 2017 ASTM F2029

Technical Parameters

- Heat - Sealing Pressure: Adjustable from 0.05 MPa to 0.7 MPa, used to simulate different heat - sealing conditions. - Heat - Sealing Time: Adjustable from 0.1s to 999.9s, ensuring that the heat - sealing process reaches a stable state. - Hot - Tack Time: Adjustable from 0.1s to 999.9s, used to evaluate the performance of materials during the hot - tacking process. - Temperature Control: Using digital P.I.D temperature - control technology, it can quickly reach the preset temperature and maintain the temperature stable. - Force Range: Multiple ranges are available, such as 0 - 200N (some devices may have a larger range). - Accuracy: Generally level 1 or higher, ensuring the accuracy of measurement results.

Send product request

Other supplier products

| Guidewires Tip Flexibility Tester | The Guidewires Tip Flexibility Tester is designed and manufactured in accordance with the relevant clauses of YY/T 1554-2017 and YY 0450.1-2003. It... | |

| Thermal - Cold Cycle meter | Standard BS 7291: Compliant for thermal cycling tests on thermoplastic pipe systems (1769 Series with pressure chamber). Adaptive Certification... | |

| Sliding Bearing Fatigue Testing chamber | Standards ASTM D2596 / ASTM D2783 / IP 239 EP, DIN 51350 / 1-5. ISO / CD 11008. VW 1444. VW 1454 Material Research and Development During the re... | |

| Guide pin anchoring force tester | The Guide Pin Anchoring Force Tester is designed to evaluate the anchoring performance of mammary positioning wires and guide needles. It ensures t... | |

| Sharp edge tester | Standards : ASTM F963 4.8. EN71-1998 8.14. GB6675-2003 A.5.9. 16CFR 1500.48 Basic Configuration: Sharp Edge Tester: 1 unit Foot switch: 1 set ... |

Same products

| Xenon Test Chamber | Seller: Standard International Group (HK) Limited | Features and Benefits 1.The use of xenon arc lamp as a light source, can simulate the full sunli... | |

| Single Cable Vertical Flame Tester | Seller: Qinsun Instruments Co., LTD | Introduction Single Cable Vertical Flame Tester is used for the vertical flame propagation of a ... | |

| Safety Helmet Flammability Tester | Seller: Qinsun Instruments Co., LTD | Product Introduction: Safety hat flame retardant performance tester for safety hat flame retarda... | |

| Furniture flammability tester | Seller: Qinsun Instruments Co., LTD | Product details Furniture flammability tester is mainly used to test the combustion performance ... | |

| Flame retardant testing machine | Seller: Qinsun Instruments Co., LTD | Feature highlights: Flame Retardant Tester is designed for testing plastic runway surface layers... |