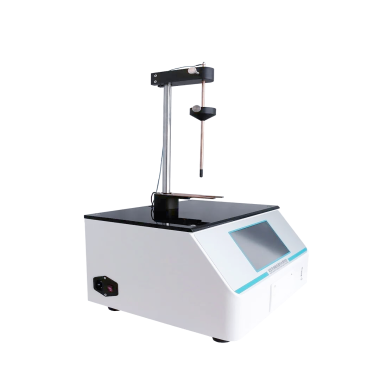

Hot Tack Tester / Heat Seal Tester

Main Uses of the Hot - Tack Tensile Tester

The hot - tack tensile tester is an instrument specifically designed to test the hot - tacking and heat - sealing properties of packaging materials. Its main uses include, but are not limited to: - Evaluating the Heat - Sealing Performance of Packaging Materials: By simulating the heat - sealing conditions of packaging production lines, it tests the strength of materials after heat - sealing, ensuring that packaging materials can maintain their integrity during transportation and storage. - Quality Control: During the production of packaging materials, regular testing with a hot - tack tensile tester can promptly identify production issues, ensuring stable and reliable product quality. - Material R & D: In the process of developing new materials, the hot - tack tensile tester can be used to evaluate the impact of different formulations and processes on the heat - sealing performance of materials, providing a basis for material optimization. - Applications in Multiple Fields: In addition to packaging materials, the hot - tack tensile tester can also be used to test the peeling and breaking properties of soft materials such as adhesives, adhesive tapes, self - adhesive labels, and paper, providing technical support for the application of these materials.

Compliance Standards

GB/T 34445 - 2017 ASTM F2029

Technical Parameters

- Heat - Sealing Pressure: Adjustable from 0.05 MPa to 0.7 MPa, used to simulate different heat - sealing conditions. - Heat - Sealing Time: Adjustable from 0.1s to 999.9s, ensuring that the heat - sealing process reaches a stable state. - Hot - Tack Time: Adjustable from 0.1s to 999.9s, used to evaluate the performance of materials during the hot - tacking process. - Temperature Control: Using digital P.I.D temperature - control technology, it can quickly reach the preset temperature and maintain the temperature stable. - Force Range: Multiple ranges are available, such as 0 - 200N (some devices may have a larger range). - Accuracy: Generally level 1 or higher, ensuring the accuracy of measurement results.

在线联系供应商

Other supplier products

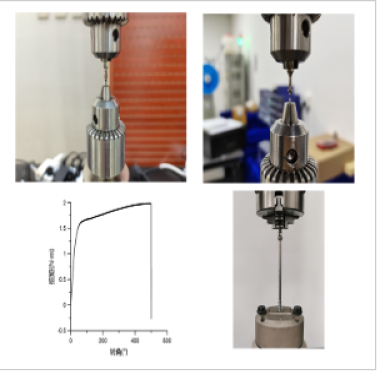

| Intervertebral Fusion Cages Torsion Fatigue Tester | Standard YY/T 0959-2014 (China): Specifies torsional fatigue testing protocols for intervertebral fusion devices, including load ratios, frequency... | |

| Puncture Strength Tester STD - NDG5 | Compliance Standards ASTM D638 (Plastics Tensile Properties) ISO 13934-1 (Textile Tensile Strength) SAE J2749 (Automotive Composite Testing) JI... | |

| Torque - to - Failure Tester | Standard YY/T 0662-2008(Chinese standard for orthopedic implant testing) ISO 5832-1(Metallic materials for surgical implants – Wrought stai... | |

| Flooring Materials Abrasion Resistance Tester | Standard ASTM D3884(Abrasion Resistance of Textile Fabrics) ISO 5470-1(Rubber or Plastics-Coated Fabrics - Abrasion Resistance) EN 660-2(Abrasio... | |

| Aluminum Ointment Tube Toughness Tester | The ductility tester for aluminum tubes is a device specifically used to detect the ductility indicators of packaging materials such as aluminum so... |

Same products

| Plastic Smoke Density Tester F313 | 卖方: Standard International Group (HK) Limited | The F313 Plastic Smoke Density Tester is a precision instrument designed to measure the specific ... | |

| Xenon Test Chamber | 卖方: Standard International Group (HK) Limited | Features and Benefits 1.The use of xenon arc lamp as a light source, can simulate the full sunli... | |

| Single Cable Vertical Flame Tester | 卖方: 上海千实精密仪器 | Introduction Single Cable Vertical Flame Tester is used for the vertical flame propagation of a ... | |

| Safety Helmet Flammability Tester | 卖方: 上海千实精密仪器 | Product Introduction: Safety hat flame retardant performance tester for safety hat flame retarda... | |

| Furniture flammability tester | 卖方: 上海千实精密仪器 | Product details Furniture flammability tester is mainly used to test the combustion performance ... |